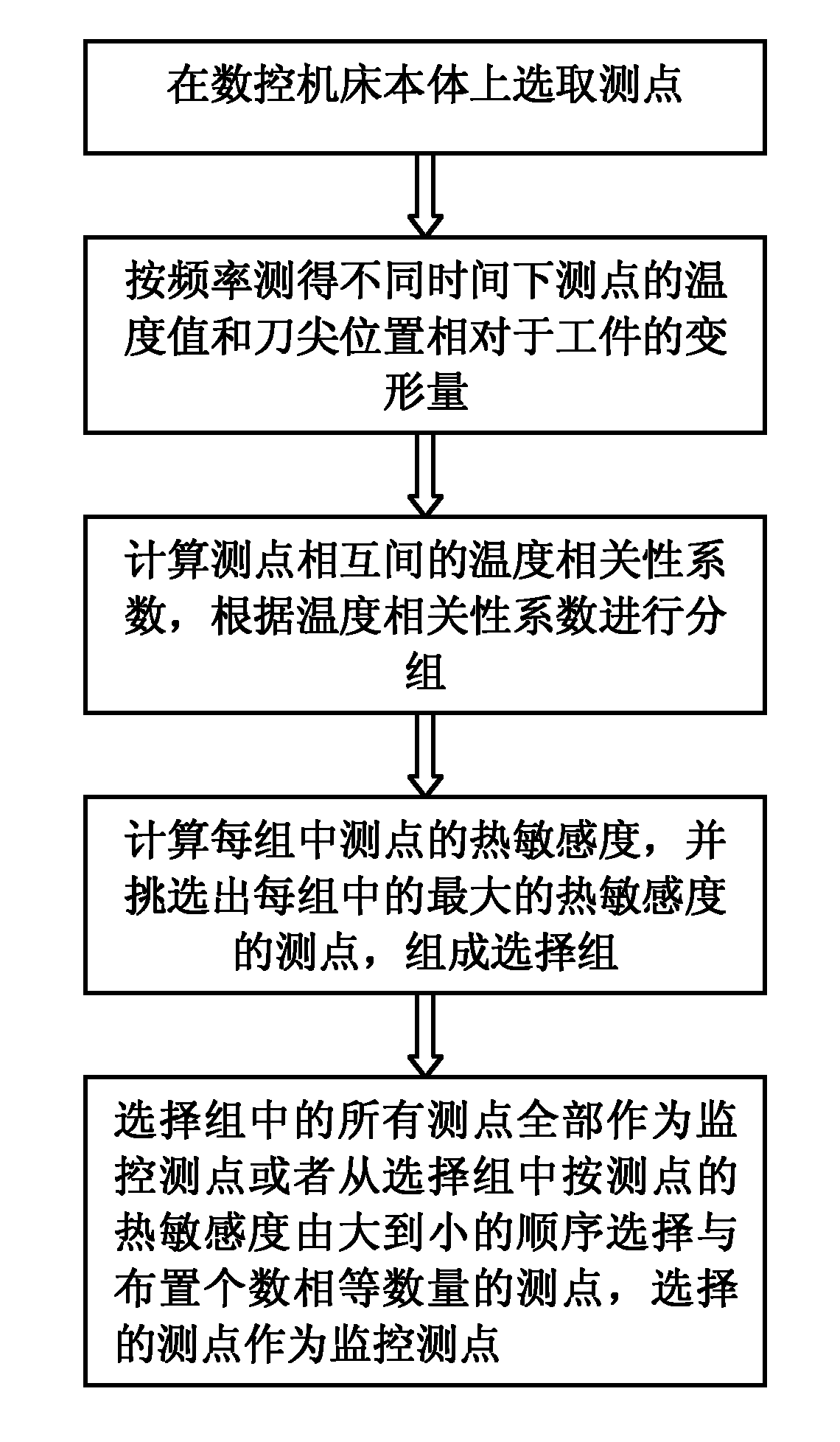

Arrangement method of heat characteristic monitoring measurement points of numerical control machine

A technology of CNC machine tools and layout methods, which is applied to measuring/indicating equipment, metal processing mechanical parts, metal processing equipment, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present invention will be further described below in conjunction with drawings and embodiments.

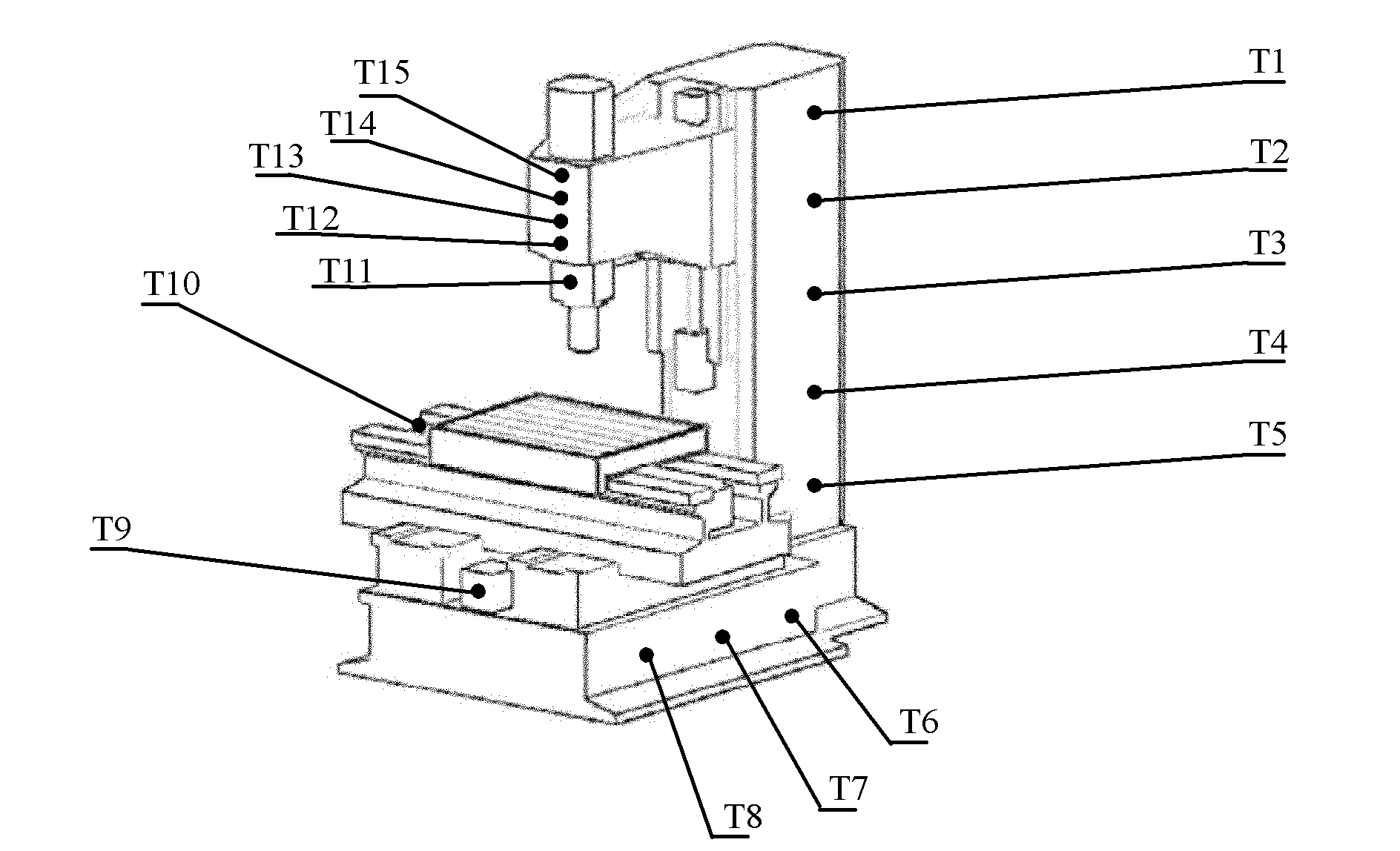

[0037] Such as figure 2 As shown, the machine tool adopts CNC milling machine XK713, and its three-way travel in the X-axis direction, Y-axis direction and Z-axis direction is 600×400×500mm. Measuring points, select different measuring points T1~T15 for detecting temperature changes on the CNC milling machine body, T1~T5 are on the column of the CNC milling machine bed, T6~T8 are on the base of the CNC milling machine bed, T9 ~T10 is on the screw bearing seat of the CNC milling machine, T11 is on the lower end cover of the spindle of the CNC milling machine, T12~T15 is on the spindle sleeve of the CNC milling machine, and then 15 thermal resistance PT100 temperature sensors are installed at the measuring points T1~T15, Used to collect temperature changes.

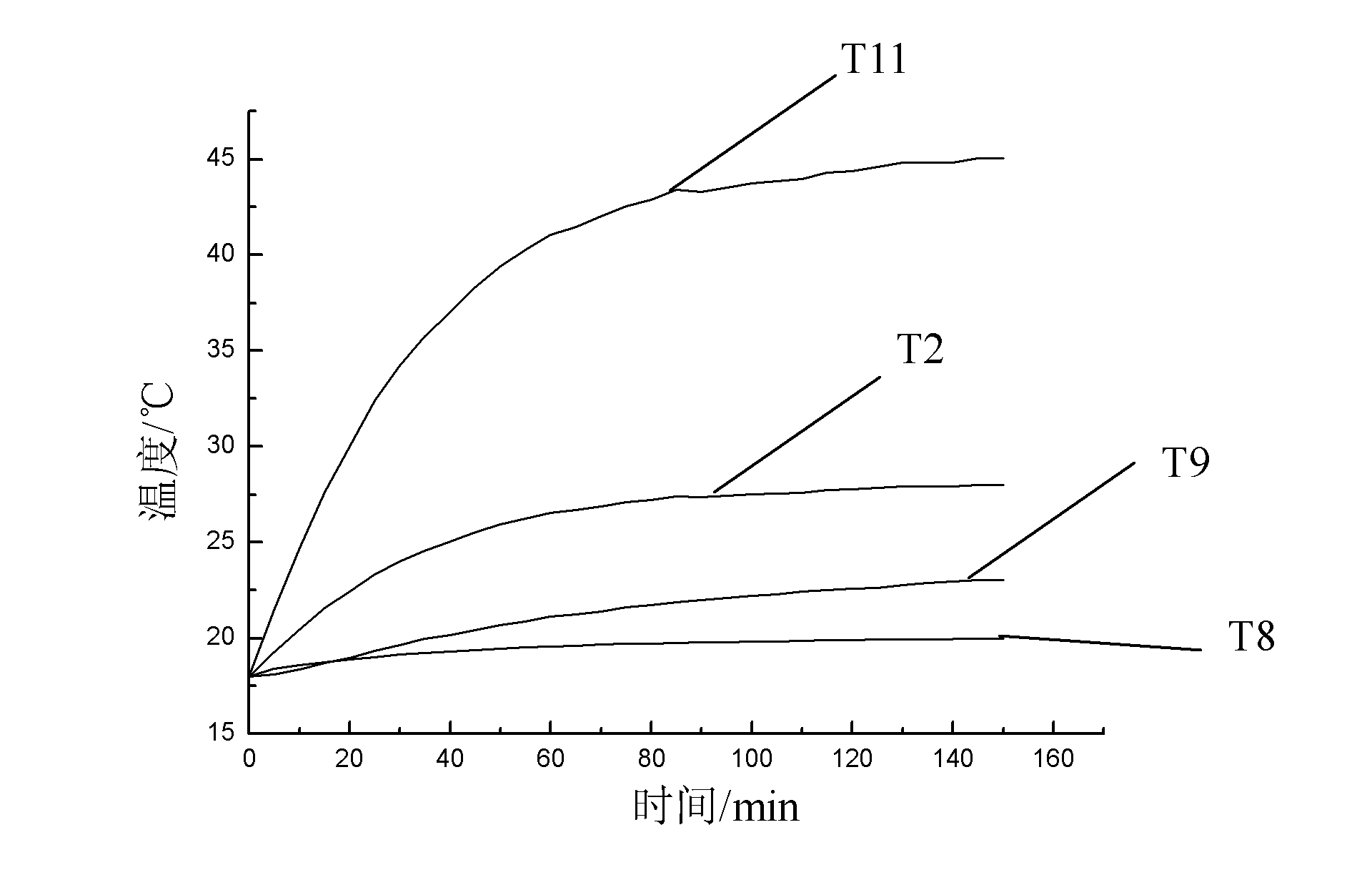

[0038] A laser displacement sensor (LK-G5000) is used to measure the deformation of the tool tip relative to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com