Fire exploration pipe-type temperature-sensitive self-startup extinguishing device

A technology of fire extinguishing device and fire detection tube, applied in fire rescue and other directions, can solve the problems of complex construction, inability to use multi-dimensional activity micro-environment, complex structure, etc., to achieve rapid response, direct and efficient fire-fighting action, and low-temperature environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

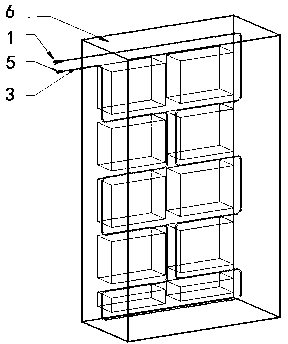

[0035] see figure 2 , this embodiment is applied to the protection of electrical control cabinets.

[0036] The external dimensions of the electrical control cabinet 6 are 2m(H)×1m(B)×0.5m(D), and there is no air exhaust port. After calculation, according to the requirements of the national standard, in order to achieve the effect of fire extinguishing, 0.7kg of FM200 (heptafluoropropane) gas needs to be injected into the cabinet within 10 seconds after the fire occurs, so as to achieve the effect of fully submerging the fire.

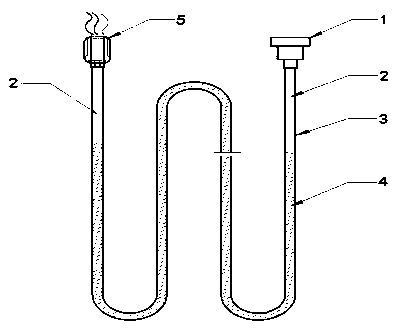

[0037] First, fill 0.7kg of FM200 (heptafluoropropane) fire extinguishing agent 4 and a fire detection tube type tubular temperature-sensing self-starting fire extinguishing device that drives nitrogen. The length is about 10 meters, and they are coiled around the electrical components in the cabinet. The distance between the pipes is 30cm~ About 40cm. The two ends of the device are placed in a high place inside the cabinet and in a position that is...

Embodiment 2

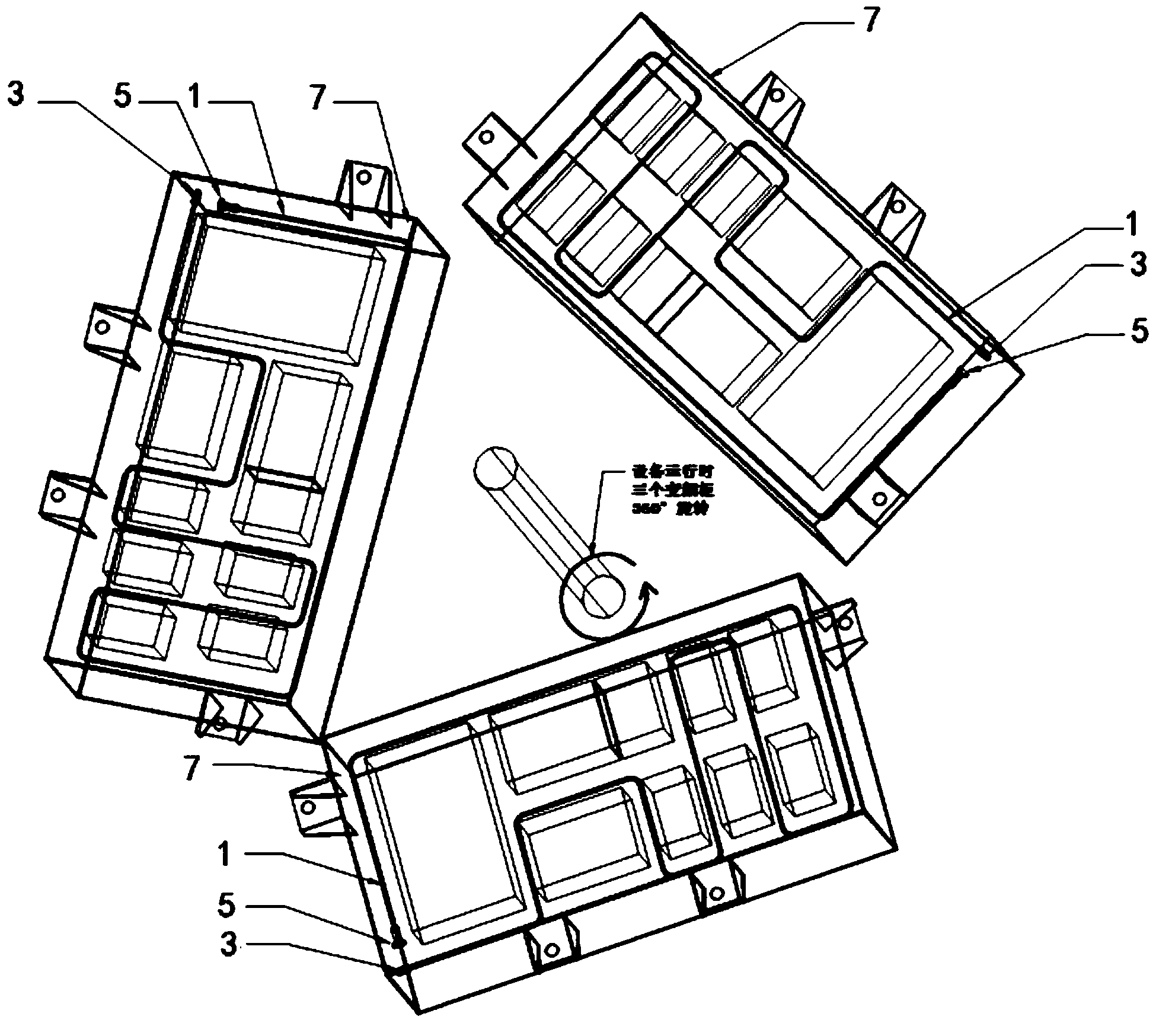

[0039] see image 3 , this embodiment is used to protect the 360-degree rotating frequency conversion electrical control cabinet.

[0040] The external dimensions of the frequency conversion electrical control cabinet 7 are 1.155m (H) × 0.59m (B) × 0.3m (D), IP65 protection level, and does not contain a discharge port. After calculation, according to the requirements of the national standard, in order to achieve the effect of fire extinguishing, it is necessary to inject 0.14kg of FM200 (heptafluoropropane) gas into the cabinet within 10 seconds after the fire occurs, so as to achieve the effect of completely submerging the fire.

[0041] First, fill 0.14kg of FM200 (heptafluoropropane) fire extinguishing agent 4 and the fire detection tube type tubular temperature-sensing self-starting fire extinguishing device that drives nitrogen, with a length of about 5 meters, coiled around the electrical components in the cabinet, and the pipe interval is 20cm to 30cm about. Combined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com