Easily welded ageing high-strength steel and heat treatment process thereof

A high-strength steel and easy-to-weld technology, applied in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve the problems of high energy consumption, long production cycle, low strength level, etc., and achieve low energy consumption, short production cycle, and production The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

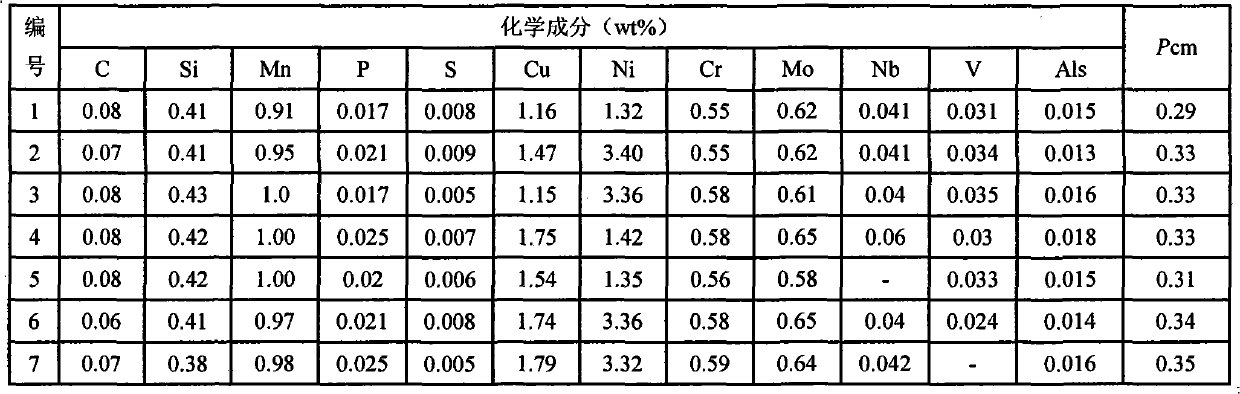

[0040] The aging high-strength steel of the present invention and its direct quenching heat treatment process are further described below in conjunction with specific examples:

[0041] Attached Table 1 lists the chemical composition of seven specific examples of the aging high-strength steel of the present invention. The production methods of these kinds of steel are as follows: the pretreated molten iron is subjected to top-bottom combined blowing on the converter, after desulfurization and slag removal, the S in the molten iron is ≤0.005%, and then the molten steel is subjected to LF and VD refining to reduce the gas in the molten steel content, and adjust the composition so that the chemical composition of molten steel meets the requirements of Table 1, and the balance is Fe and unavoidable impurities. The molten steel whose composition meets the requirements in Table 1 is cast into a slab with a section of 200-300mm×1650mm through a continuous casting machine. Then the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com