Preparation method of zinc oxide varister

A technology of zinc oxide and varistors, applied in the direction of resistors, resistance manufacturing, varistor cores, etc., can solve the inability to create more ideal or more economical process conditions, limitations, inability to select high-impedance grain boundary layer components and Dosage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

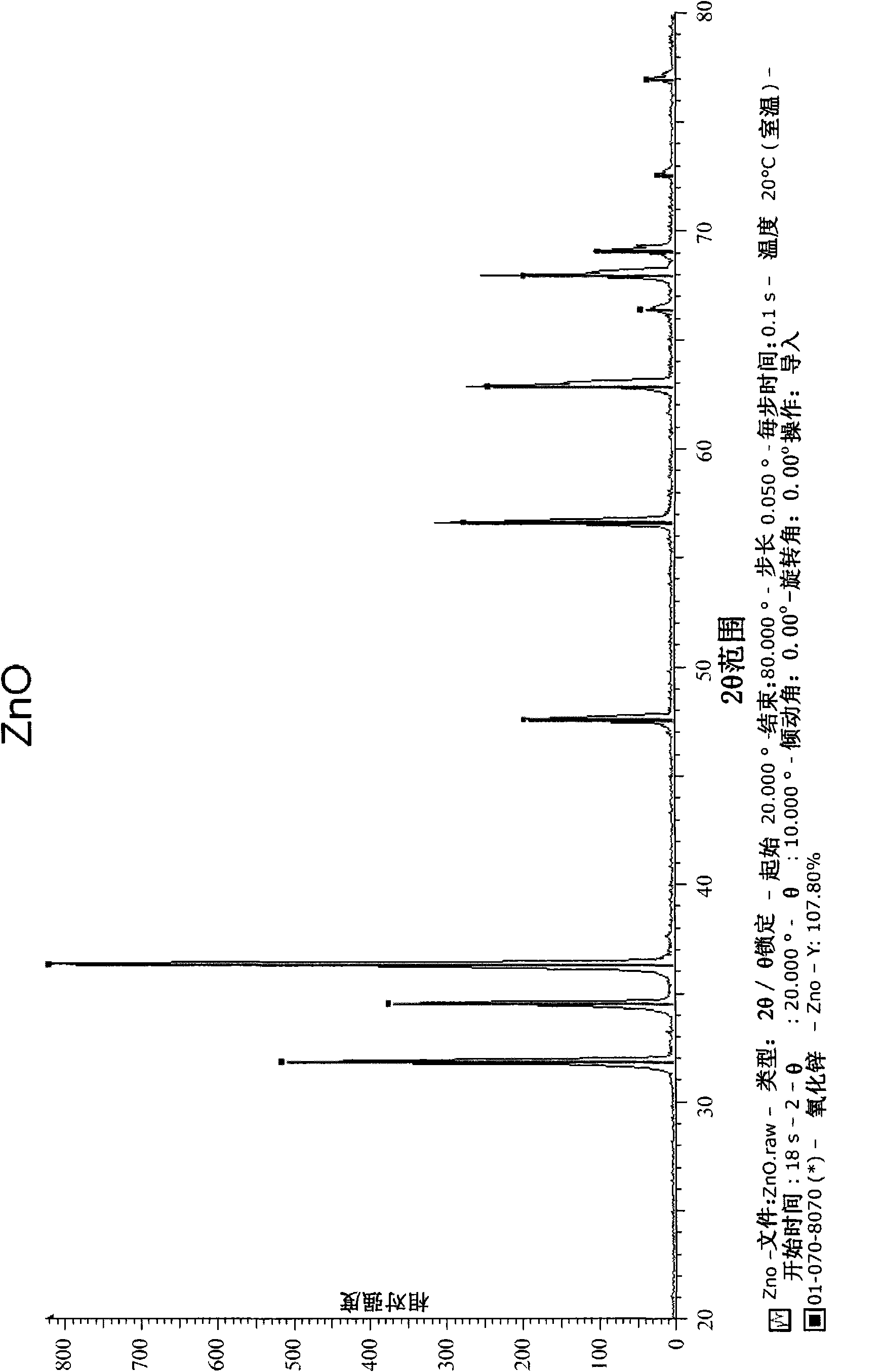

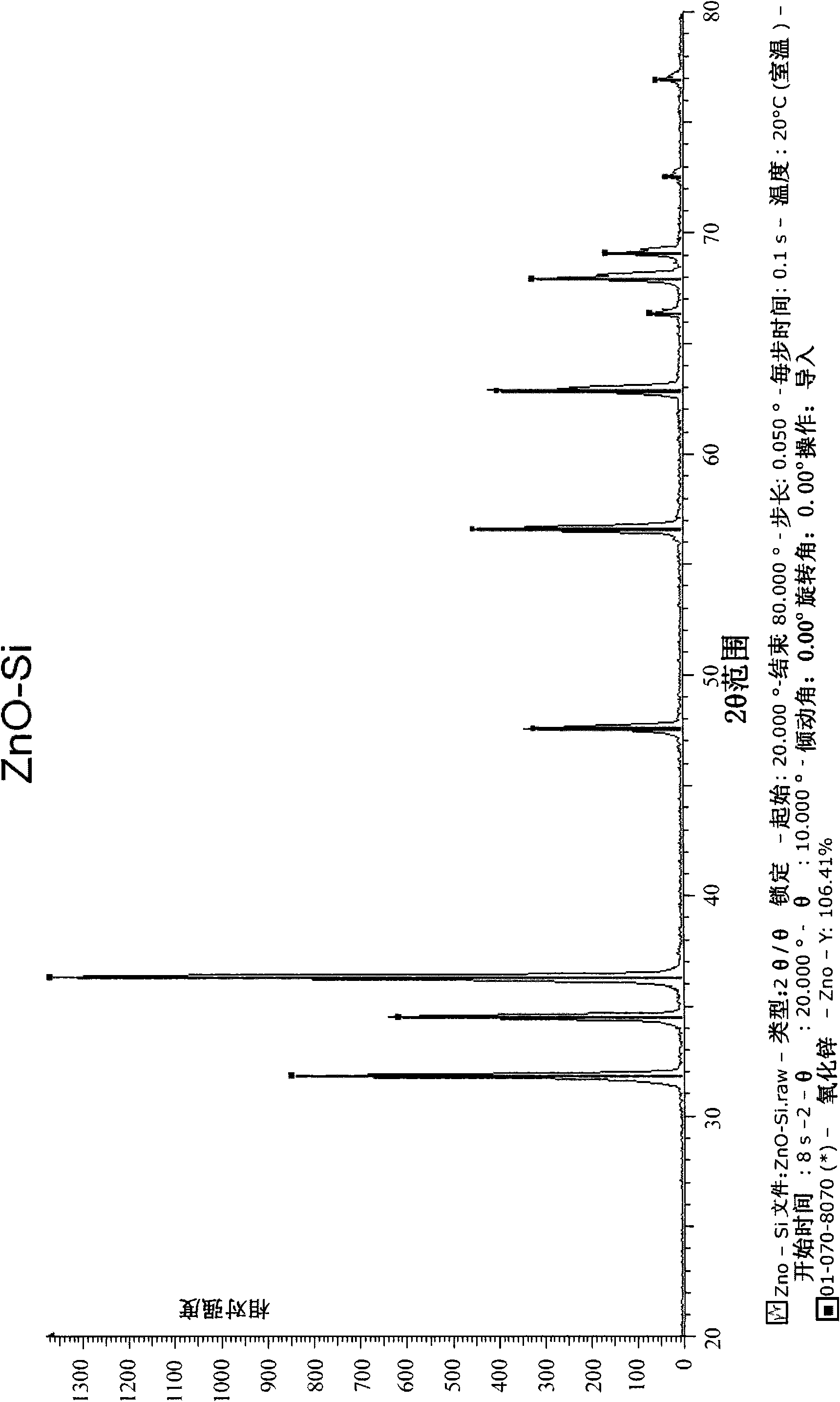

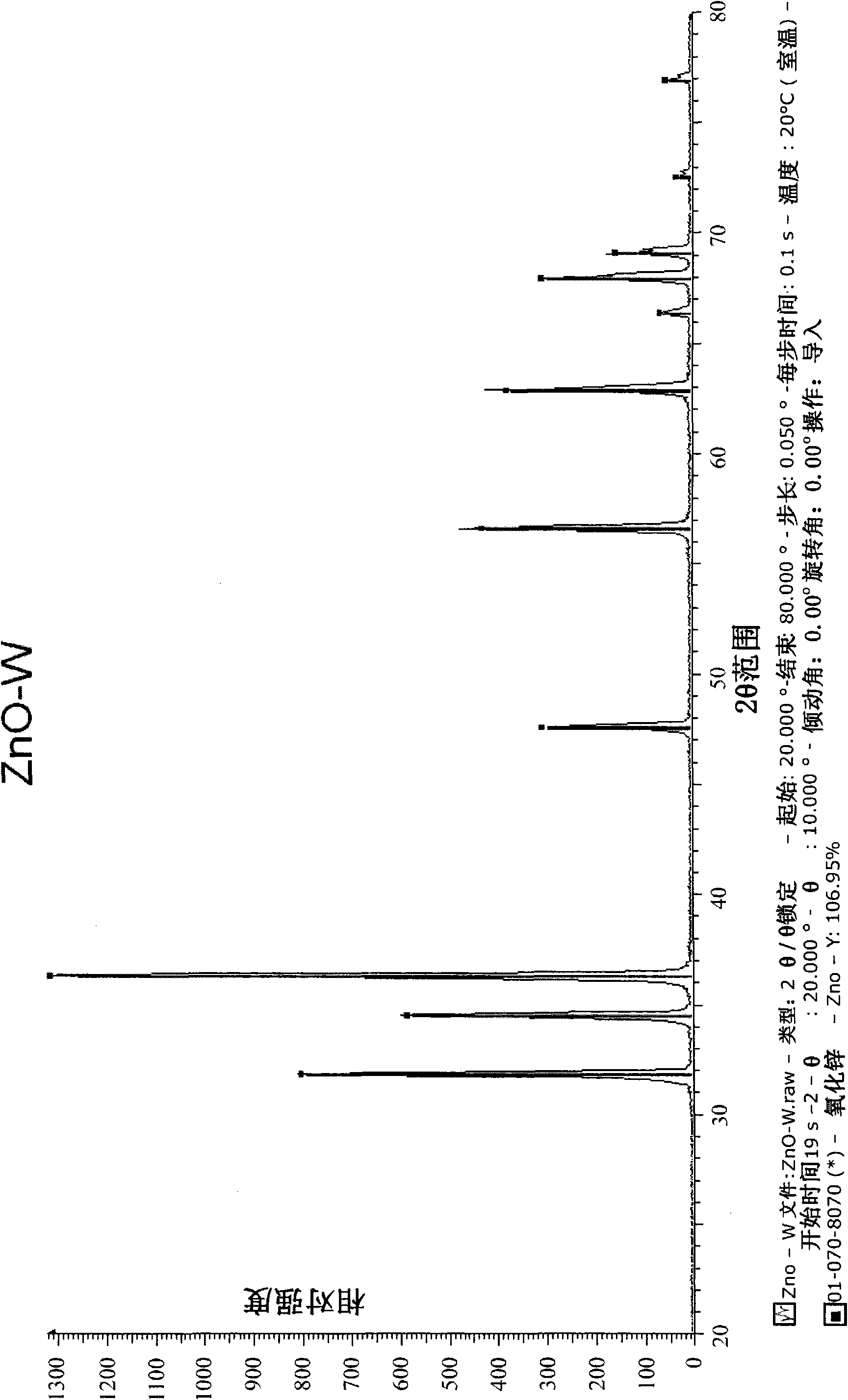

Image

Examples

preparation example Construction

[0030] The preparation method of the zinc oxide varistor of the present invention includes the following steps:

[0031] a. Prefabricated zinc oxide crystal grains containing doped ions;

[0032] According to the principle of crystallography, a solution containing zinc ions and a solution containing doped ions are prepared, and then nanotechnologies such as coprecipitation method or sol-gel process are used to obtain the precipitate, which is then heated Decompose to prepare zinc oxide crystal grains containing doped ion components.

[0033] Zinc oxide crystal grains can be doped with one or more ionic components, wherein the doping amount of ionic components is less than 15 mol% of the zinc oxide content, but less than 10 mol% is a preferred embodiment, and less than 2 mol% is the best Examples.

[0034] The doping ion component of zinc oxide crystal grains is selected from silver (Ag), lithium (Li), copper (Cu), aluminum (Al), cerium (Ce), cobalt (Co), chromium (Cr), indium (In) ,...

Embodiment 1

[0059] A chemical co-precipitation method was used to prepare the zinc oxide crystal grain samples listed in Table 1 doped with a single ion component of 1 mol%. The sintering material code-named G1-00 is prepared by chemical co-precipitation method, and its composition and weight are as follows:

[0060]

[0061]

[0062] According to the zinc oxide grain sample: G1-00 sintered material, the weight ratio is 100:10 or 100:15 or 100:30, and then the mixture is uniformly mixed at 1000kg / cm 2 The pressure is pressed into a wafer, and then sintered at a sintering temperature of 1065°C for 2 hours, and then the silver electrode is completed at 800°C, and a wafer-type zinc oxide surge absorber is made. The pressure-sensitive properties of various zinc oxide varistors were measured, and the results are shown in Table 1.

[0063] It can be seen from Table 1 that when the same sintering material is used, the pressure-sensitive characteristics of the zinc oxide varistor will vary with the ty...

Embodiment 2

[0069] The chemical co-precipitation method was used to prepare the zinc oxide crystal grain samples listed in Table 2 doped with different mol% single ion components. The G1-00 sintered material prepared in Example 1 was used.

[0070] According to the zinc oxide crystal grain sample: G1-00 sintered material, the weight ratio is 100:10, and the wafer-type zinc oxide varistor is prepared under the same conditions as in Example 1, and then the pressure of various zinc oxide varistors is measured. Sensitive performance, the results are shown in Table 2.

[0071] It can be seen from Table 2 that when the zinc oxide crystal grains contain a single doping ion component and the same sintering material is used, the pressure-sensitive characteristics of the zinc oxide varistor will vary with the use of the doping ion component of the zinc oxide crystal grains. .

[0072] Therefore, the pressure-sensitive characteristics of the zinc oxide varistor can be adjusted by controlling the type and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com