Micro-wave vacuum equipment

A technology of microwave vacuum drying and equipment, which is applied in the direction of drying solid materials, drying chamber/container, lighting and heating equipment, etc. It can solve the problems of great influence on the quality of dried food, high energy consumption, long time, etc., and achieve drying or concentration The effect of fast speed and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

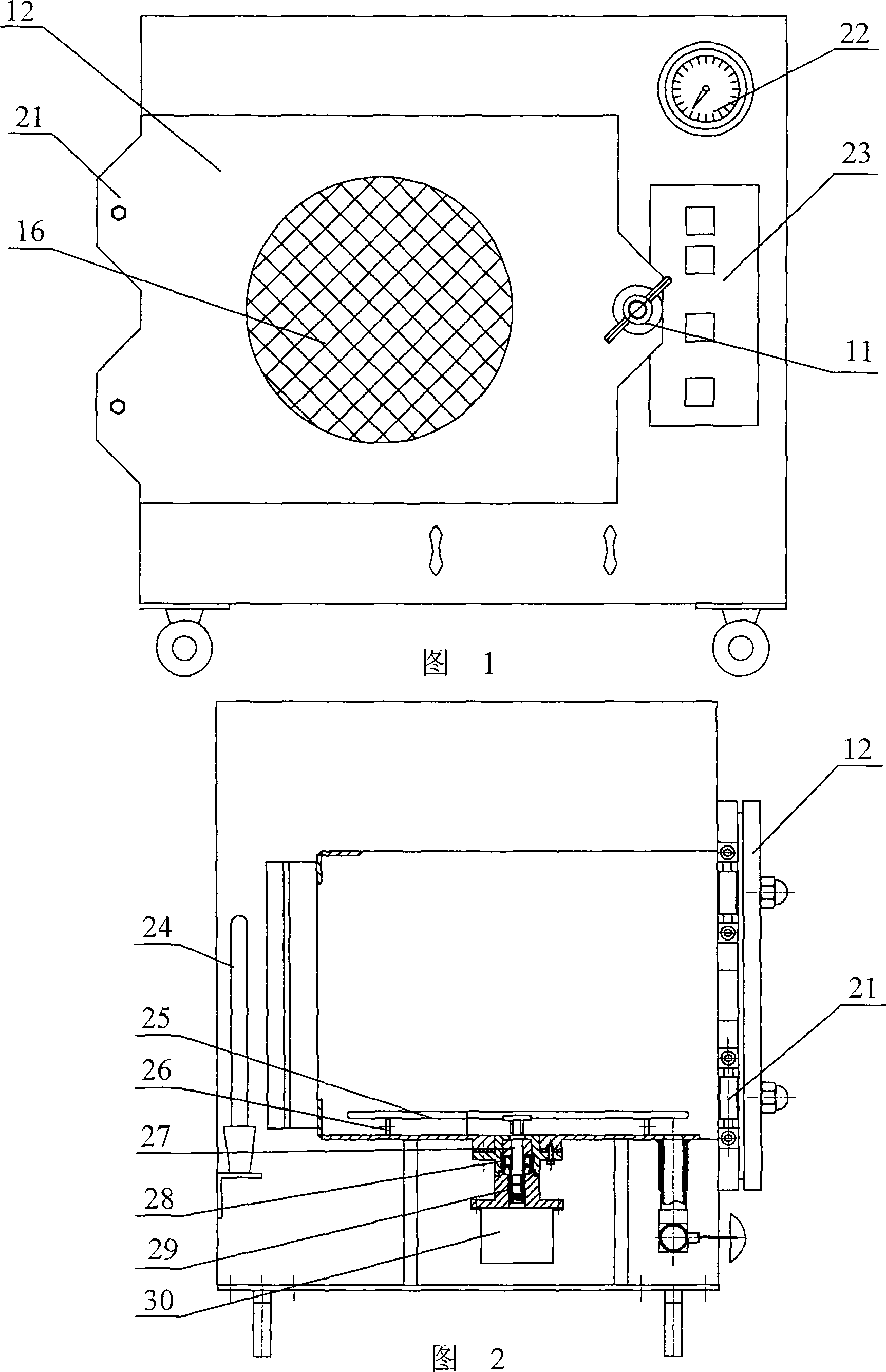

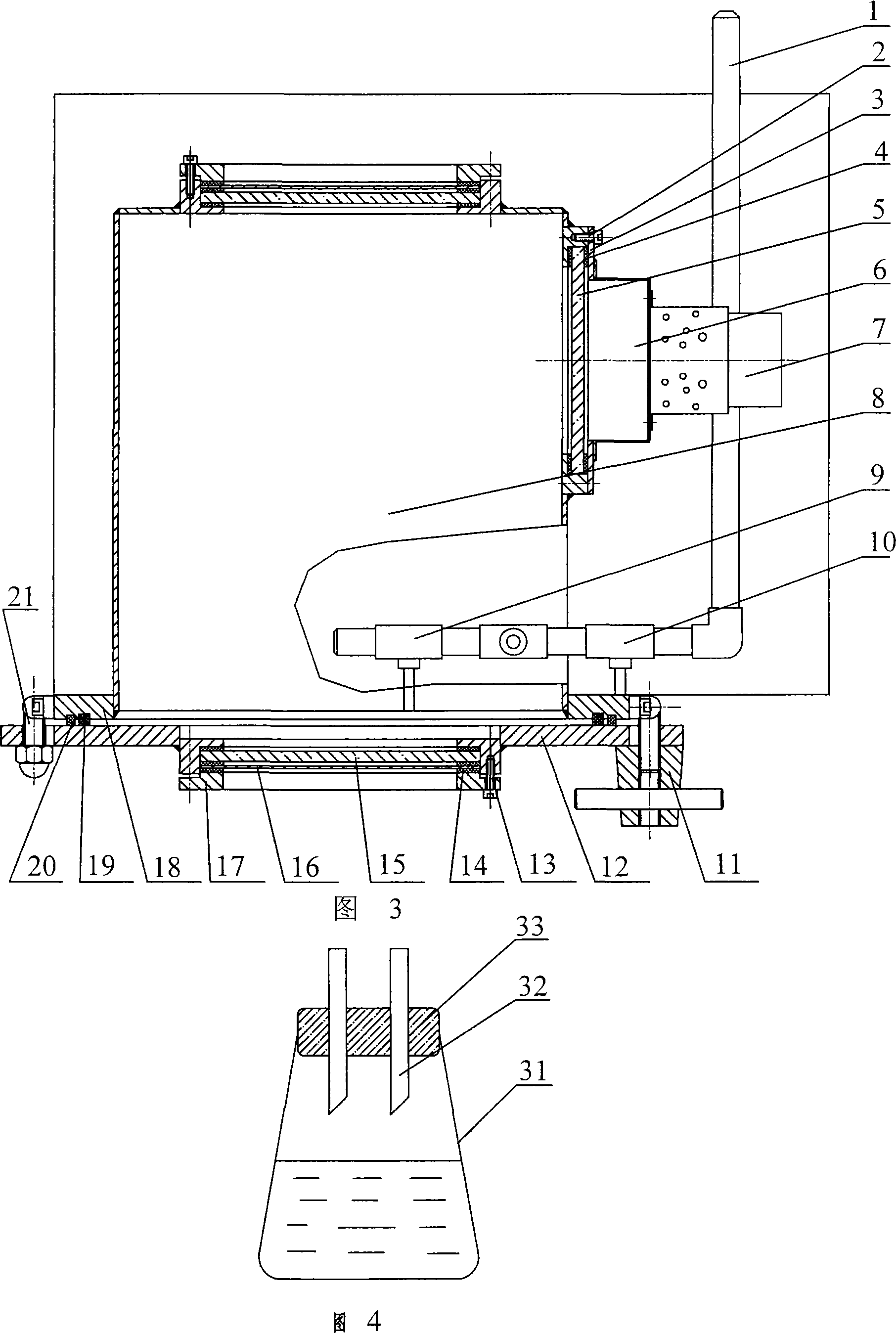

[0012] In the figure, 1 is the vacuum connection, 2 is the hexagonal bolt, 3 is the pressure plate, 4 is the gasket, 5 is the polypropylene plate, 6 is the waveguide, 7 is the magnetron, 8 is the drying chamber (resonant cavity), 9 is Vacuum breaking valve, 10 is the vacuum pipeline valve, 11 is the lock nut, 12 is the door, 13 is the hex nut, 14 is the gasket, 15 is the mirror glass, 16 is the metal mesh, 17 is the gland, 18 is the door method Lan, 19 is a rectangular silicone rubber sealing ring, 20 is a metal sealing ring, 21 is a door hinge, 22 is a vacuum gauge, 23 is a controller, 24 is a lamp, 25 is a turntable, 26 is a roller, 27 is a rotating shaft, and 28 is a Skeleton oil seal, 29 is a shaft coupling, and 30 is a motor.

[0013] As shown in the figure: a vacuum gauge 22, an operation controller 23 and a lamp 24 are arranged on the outer wall of the drying chamber 8, and an opening and closing door 12 for taking and putting materials is arranged on the wall of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com