High-temperature-resistant photo-curing material and preparation method thereof

A light-curing material and high-temperature-resistant technology, used in additive processing, manufacturing tools, additive manufacturing, etc., can solve the problems of poor high temperature resistance and easy cracking, and achieve the effect of strong high temperature resistance, not easy to crack, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

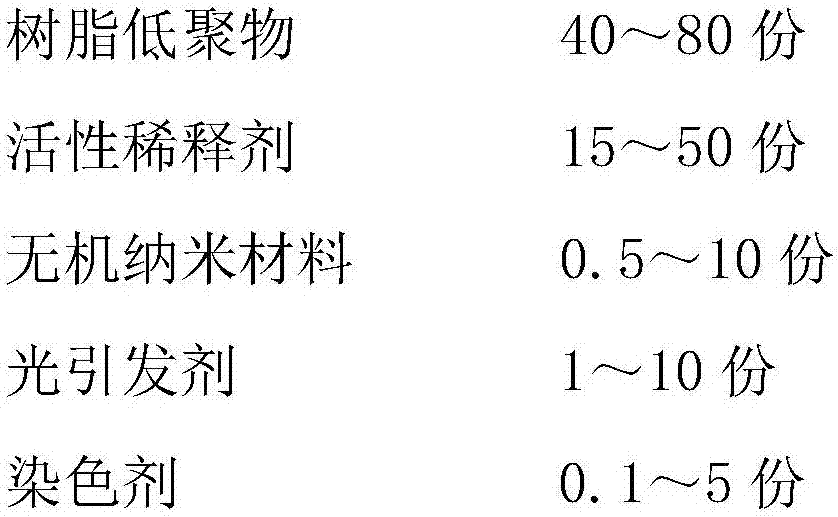

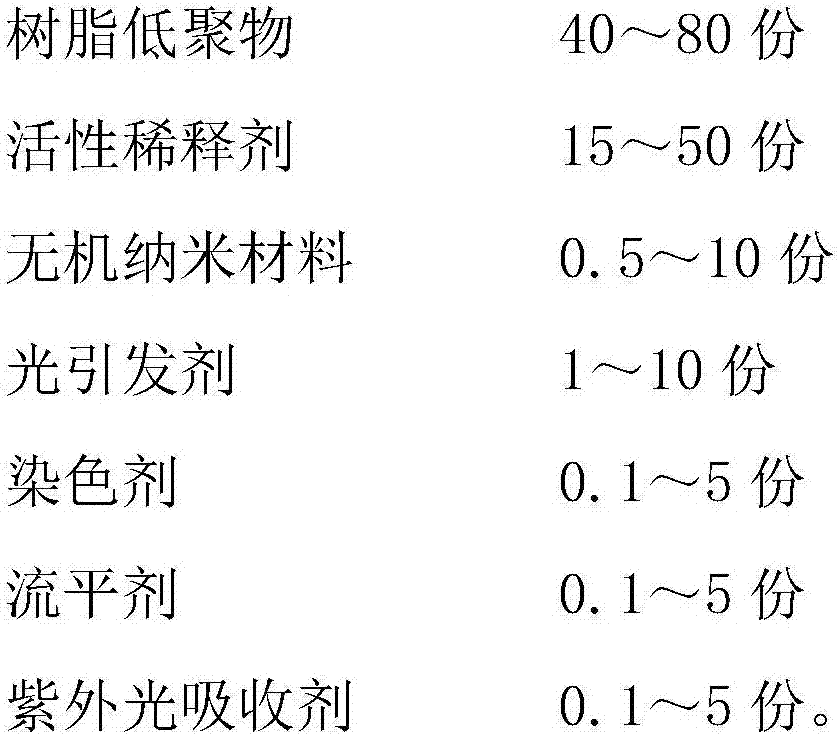

Method used

Image

Examples

Embodiment 1

[0042]In parts by weight, 2 parts of nano-montmorillonite and 2 parts of rectorite were added to 16 parts of 3,3,5-trimethylcyclohexyl acrylate, 15 parts of 1,6-hexanediol diacrylate Ultrasonic vibration in the mixed reactive diluent formed was 20~30min, then add the composition of 33 parts of bisphenol A type epoxy acrylates and 27 parts of bisphenol A type epoxy resins, then add 2 parts of benzoin diethyl ether, 1 Part 1-hydroxycyclohexyl phenyl ketone photoinitiator, 1.3 parts of dyeing agent, 0.4 part of leveling agent and 0.3 part of ultraviolet light absorber; The selected dyeing agent is iron oxide red, and the selected ultraviolet light absorber is Phenyl o-hydroxybenzoate, the selected leveling agent is BYK-056 from BYK Company; every time a material is added, it is ultrasonically oscillated for 15 minutes, and after the last material is added and oscillated for 15 minutes, the whole body continues to oscillate for 30 minutes until the liquid is uniform, and then the p...

Embodiment 2

[0047] In parts by weight, add 0.5 parts of nano-montmorillonite to a mixed reactive diluent consisting of 10 parts of tripropylene glycol diacrylate and 5 parts of isobornyl methacrylate and ultrasonically vibrate for 20 to 30 minutes, and then add 40 parts of Diacrylate (viscosity=12000~15000cps, 25°C) oligomer resin with ester ring, then add 1 part of phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide photoinitiator, 0.1 part of malachite green, 0.1 part of leveling agent and 0.1 part of UV absorber; the selected leveling agent is BYK-056 from BYK, and the selected UV absorber is phenyl o-hydroxybenzoate; One material is ultrasonically oscillated for 15 minutes. After the last material is added and oscillated for 15 minutes, the whole body continues to oscillate for 30 minutes until the liquid is uniform, and then the prepared resin is printed out by the 3D printing equipment according to the predetermined process. The resin sample is tested according to the high temperature t...

Embodiment 3

[0050] In parts by weight, 5 parts of nano-titanium dioxide and 5 parts of montmorillonite were added to 20 parts of tripropylene glycol diacrylate, 20 parts of isobornyl methacrylate, 10 parts of 3,3,5-trimethylcyclohexane Ultrasonic vibration in the mixed active diluent composed of base acrylate for 20-30 minutes, then add 50 parts of diacrylate oligomer resin with ester ring, 30 parts of bisphenol A type epoxy acrylate composition, and then sequentially add 10 parts of 2-phenylbenzyl-2-dimethylamine-1-(4-morpholine benzylphenyl) butanone photoinitiator, 5 parts of malachite green, 5 parts of leveling agent and 5 parts of ultraviolet light absorber Phenyl o-hydroxybenzoate; the selected leveling agent is BYK-056 from BYK; every time a material is added, it is ultrasonically oscillated for 15 minutes, and after the last material is added and oscillated for 15 minutes, the whole body continues to oscillate for 30 minutes until the liquid is uniform, and then the prepared The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com