Heat pump-microwave combined drying device

A combined drying and microwave technology, used in lighting and heating equipment, heating to dry solid materials, drying solid materials, etc., to achieve the effect of simple and convenient use, maintenance and repair, simple form and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

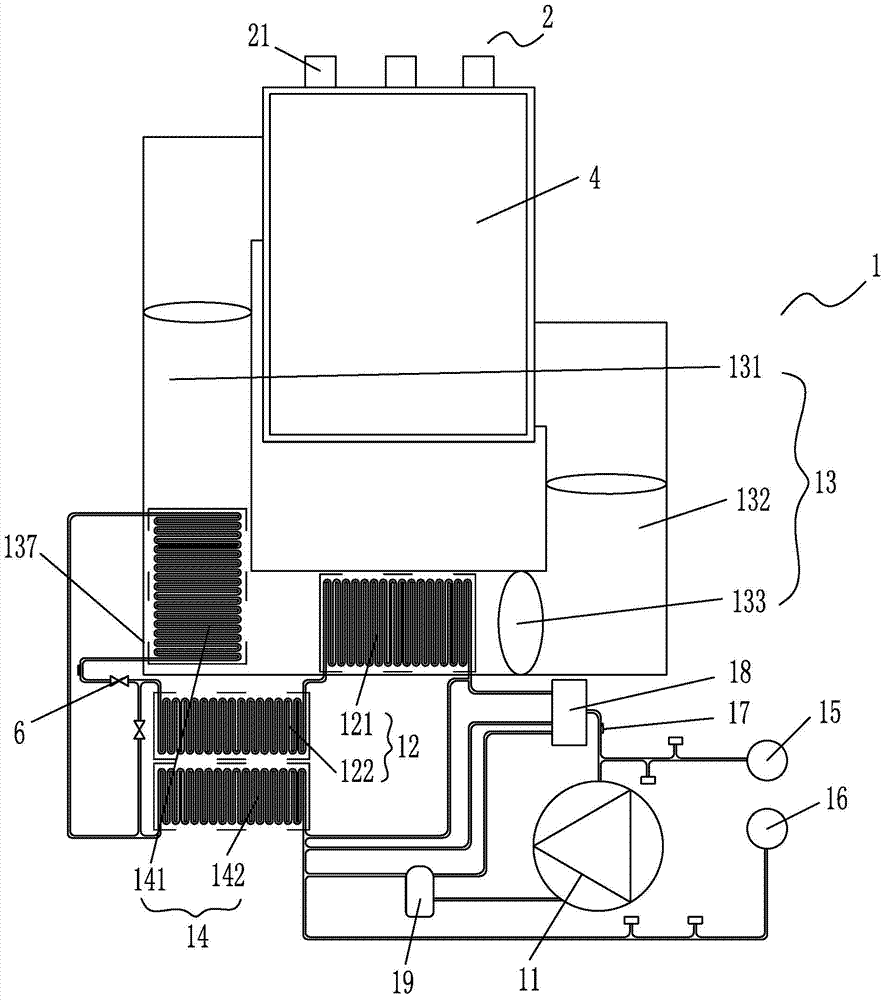

[0098] Embodiment 1: heat pump drying

[0099] First, the start temperature, stop temperature and fan frequency are respectively set on the control system 3 through the touch screen 35. When the temperature of the dry material is higher than the set stop temperature, the compressor 11 stops automatically. When the material temperature is lower than the set start temperature, the heat pump starts automatically. So cycle. Then open the left and right air ducts 131, 132 and the circulation fan 133. After the circulation fan 133 is running, the heat pump is turned on, and the compressor 11 runs after 3 minutes. The air in the left and right air passages 131, 132 flows through the evaporator 141 and the condenser 121 in sequence under the action of the circulating fan 133; the refrigerant flows through the compressor 11, the condenser 121, the throttle valve 6 and the evaporator in sequence 14. When the humid air coming out of the drying chamber 4 flows through the evaporator 1...

Embodiment approach 2

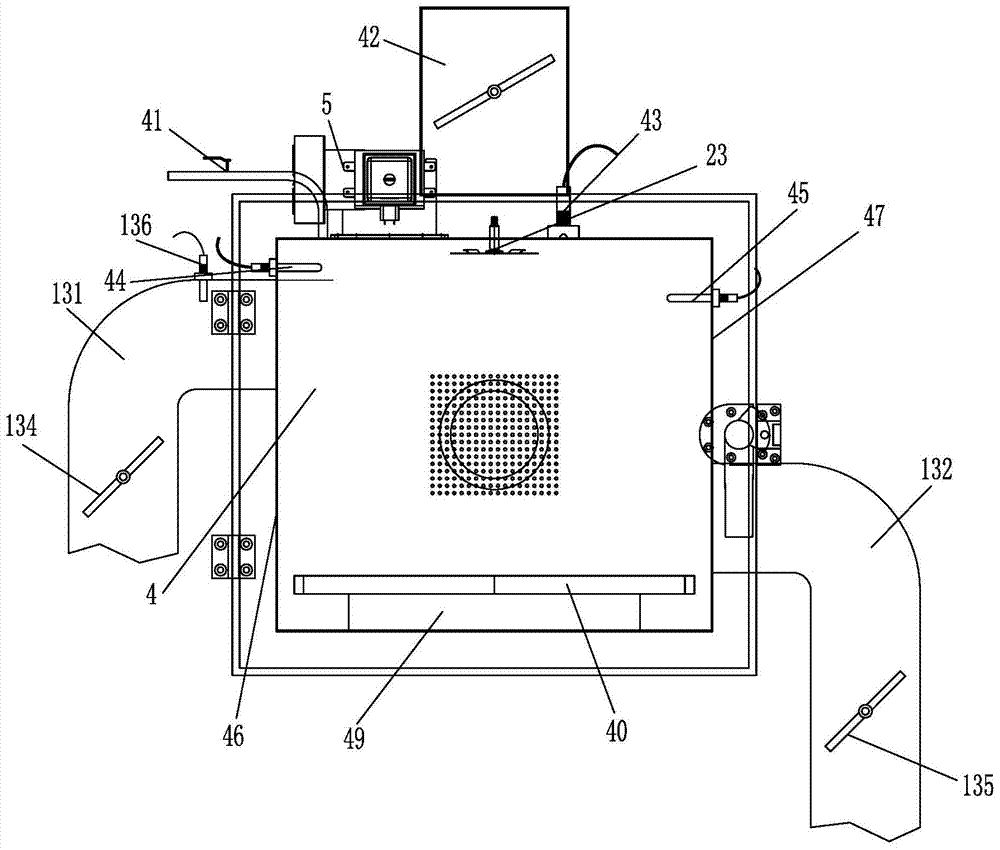

[0100] Embodiment 2: microwave drying

[0101] First, the microwave power adjustment is set in the control system 3 through the touch screen 35 . There are 3 levels of microwave input, microwave Ⅰ, microwave Ⅱ, and microwave Ⅲ, and correspond to 3 settings of temperature Ⅰ, temperature Ⅱ, and temperature Ⅲ. When temperature I is set, when the material temperature is lower than the temperature set by I, the microwave display power corresponds to the power set by temperature I. When the material temperature is higher than the temperature set by temperature Ⅰ and lower than the temperature set by temperature Ⅱ, the power displayed by the microwave is the power set by the corresponding temperature Ⅱ. The same is true for the set temperature III. Then turn on radiator 5, microwave source magnetron 21, and stirrer 23. During operation, the microwave source magnetron 21 enters the material inside the drying chamber 4 through the energy feed port 22, and rapidly generates a large a...

Embodiment approach 3

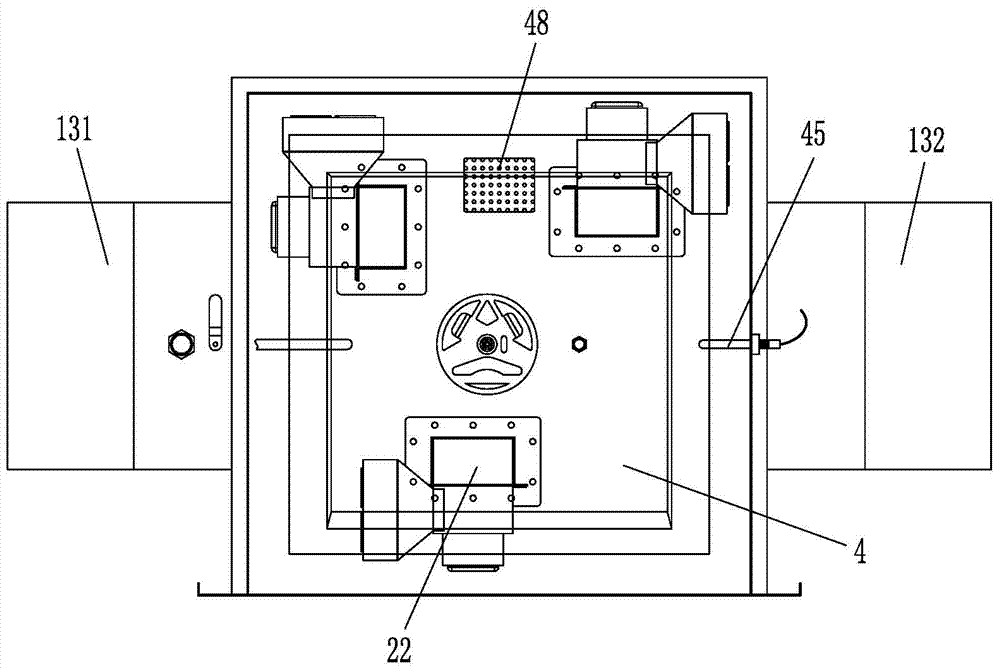

[0102] Embodiment 3: heat pump-microwave combined drying

[0103] According to the drying needs, the drying sequence of the control system 3 in the combined drying, heat pump and microwave drying modes is selected through the touch screen 35, and the experimental conditions are set according to the setting methods described in the above-mentioned embodiment 1 and embodiment 2 respectively. Set the running time of each drying mode, press the timing start button, the selected working mode starts to run, and the timing starts. When the running time is consistent with the set working time, the working mode stops working.

[0104] In the present invention, the setting of each valve in the system is not limited to figure 1 As shown, in order to make the system run normally and facilitate maintenance, valves can be added to the relevant parts of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com