Thermal driving desorption restoration method of polluted soil

A technology of polluted soil and remediation method, applied in the field of environmental protection equipment, can solve the problems of environmental risks and land use function restrictions, increased transportation costs of polluted soil, limited disposal of polluted soil, etc. The effect of subsequent use and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

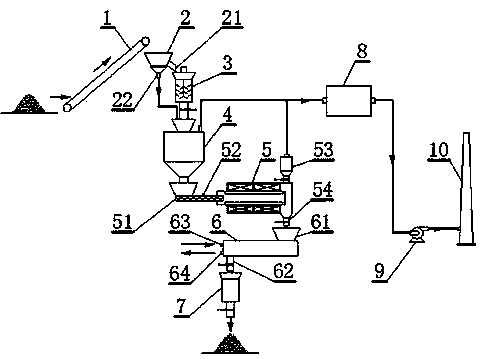

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

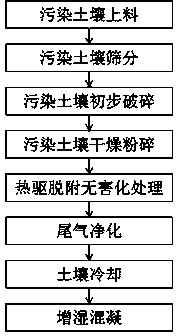

[0035] The thermal flooding and desorption repairing method for polluted soil provided by the present invention uses the polluted soil thermal flooding desorption repairing system to restore organic matter and heat-sensitive heavy metal contaminated soil, and the repaired soil meets the follow-up land use standards. The specific steps include:

[0036] Step 1: Contaminated soil feeding. The contaminated soil is transported to the screening machine 2 through the soil feeding belt 1, and the soil feeding belt 1 is used to measure the soil feeding when conveying the contaminated soil, and at the same time, the soil feeding amount is controlled by controlling the speed of the soil feeding belt 1.

[0037] Step 2: Contaminated soil screening. The polluted soil entering the screening machine 2 is divided into soil clods with a particle size larger than 80mm and so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com