Grate type titanium-based PbO2 electrode for nonferrous metal electrodeposition and preparation method of grate type titanium-based PbO2 electrode

A non-ferrous metal, electrowinning technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of short life, high electrode cost, uneven deposition layer, etc., to prolong the service life, simple preparation method, improve catalytic active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

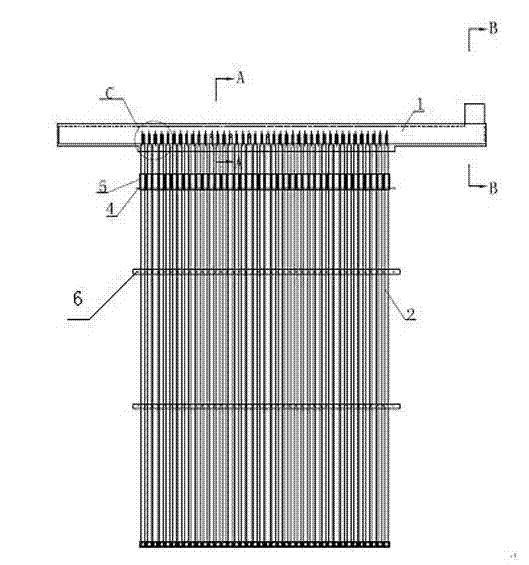

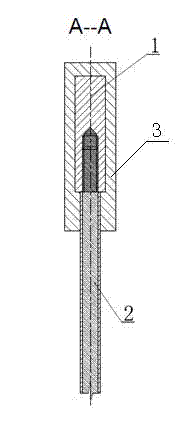

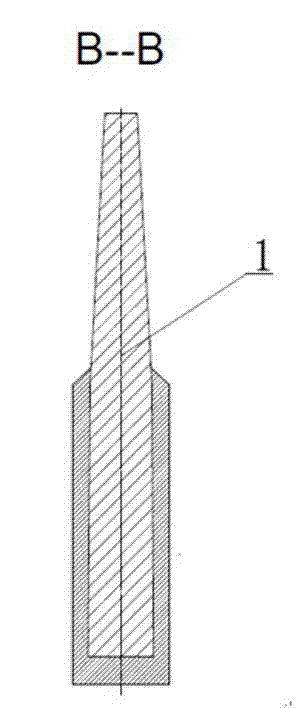

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a titanium rod or tube with a diameter of 6mm is quenched and tapped. After mechanical sandblasting and coarsening, it is placed in a 20% NaOH solution and heated to boil for 30 minutes to remove oil, and then placed in a mixed solution for 5 minutes to remove Oxide film is activation treatment, the mixed solution is 10% HNO 3 +20%HC1+5%HF solution, finally rinse with deionized water, blow dry, and place it in a drying box for 12 hours; punch a row of holes at the bottom of the copper conductive row 1 and tap the holes in the The top of the tapped titanium substrate is screwed into the hole and connected to the copper conductive bar, and then filled with lead to form a lead coating layer 3, which is combined into a fence-type titanium-based PbO for non-ferrous metal electrowinning with a size of 976mm×620mm 2 electrode.

[0030] Then proceed as follows: Pb-Ag-TiO is electrodeposited sequentially on the titanium s...

Embodiment 2

[0033] The 3mm diameter titanium rod is quenched and tapped as a whole, after mechanical sandblasting and coarsening, it is placed in a 30% NaOH solution to heat and boil to remove oil for 2 hours, and then put in a concentration of 15% HNO 3 +10%HC1+10%HF solution is pickled for 10min to remove the oxide film and then activated, finally rinsed with deionized water, blown dry, placed in a drying box for 24h until use; lay a row at the bottom of copper conductive row 1 The hole is tapped in the hole, and the top of a set of tapped titanium substrate is screwed into the hole and connected to the copper conductive bar, and then filled with lead to cover it to form a fence type titanium-based PbO for non-ferrous metal electrowinning 2 electrode.

[0034] Then proceed as follows: Pb-Ag-TiO is electrodeposited sequentially on the titanium substrate of the electrode 2 Composite layer, then alkaline electroplated α-PbO 2 Composite layer and acid plating β-PbO 2 The composite layer is obtai...

Embodiment 3

[0037] Choose a titanium rod with a diameter of 3mm~8mm or a titanium tube with a diameter of 6mm~12mm for quenching and tapping. After mechanical sandblasting and coarsening, put it in a 50% NaOH solution to heat and boil to remove oil for 1 hour, and then add 20% HNO. 3 +30%HC1+15%HF solution is pickled for 2min to remove the oxide film and then activated. Finally, it is cleaned with deionized water, blown dry, and placed in a drying box for 2h. Tapping in the hole, screw the top of a group of tapped titanium substrates into the hole and connect with the copper conductive bar, and then pour lead and wrap them to form a fence electrode.

[0038] Then proceed as follows: Pb-Ag-TiO is electrodeposited sequentially on the titanium substrate of the electrode 2 Composite layer, then alkaline electroplated α-PbO 2 Composite layer and acid plating β-PbO 2 The composite layer is obtained to obtain a titanium rod 2 for non-ferrous metal electrowinning. The electrodeposited Pb-Ag-TiO 2 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com