Titanium-based beta-MnO2-RuO2 composite coating anode plate and preparation method and application thereof

A composite coating and anode plate technology, applied in the coating, metal material coating process, electrodes, etc., can solve the problems of high cell voltage and short life, and achieve low cell voltage, long service life and excellent catalytic activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

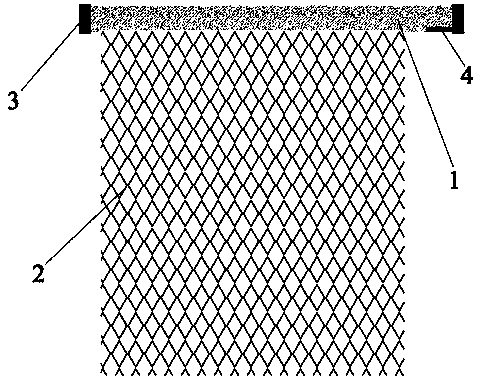

[0031] Embodiment 1: as figure 1 As shown, the titanium-based β-MnO in this example 2 -RuO 2 Composite coated anode plate, including titanium-clad copper conductive beam 1, titanium mesh substrate 2, silicone sleeve 3, conductive head 4, silicone sleeve 3 sets are set at the left and right ends of titanium-clad copper conductive beam 1, titanium-clad copper conductive beam 1 end The bottom end of the head exposes copper as the conductive head 4, the conductive head 4 is connected to an external power supply, the titanium mesh substrate 2 is fixed on the lower end of the titanium-clad copper conductive beam 1, and the titanium mesh substrate 2 is sequentially coated with a gradient Ir-Ta-Sn-SbOx Interlayer and β-MnO 2 -RuO 2 Composite surface active layer; the thickness of the gradient Ir-Ta-Sn-SbOx intermediate layer is 5µm, β-MnO 2 -RuO 2 The thickness of the composite surface active layer is 150µm; the titanium mesh substrate 2 is a diamond-shaped mesh structure with a ...

Embodiment 2

[0041] Example 2: Titanium-based β-MnO of this example 2 -RuO 2 Composite coated anode plate, including titanium-clad copper conductive beam, titanium mesh substrate, silicone sleeve, conductive head, the silicone sleeve set is set at the left and right ends of the titanium-clad copper conductive beam, and the bottom end of the titanium-clad copper conductive beam is exposed as copper. Conductive head, the conductive head is connected to an external power supply, and the titanium mesh substrate is fixed at the lower end of the titanium-clad copper conductive beam. The titanium mesh substrate is coated with a gradient Ir-Ta-Sn-SbOx intermediate layer and β-MnO in sequence. 2 -RuO 2 Composite surface active layer; the thickness of the gradient Ir-Ta-Sn-SbOx intermediate layer is 8µm, β-MnO 2 -RuO 2The thickness of the composite surface active layer is 200µm; the titanium mesh substrate 2 is a porous structure with a thickness of 5mm and a pore diameter of 8mm;

[0042] Titan...

Embodiment 3

[0051] Embodiment 3: Titanium-based β-MnO of this embodiment 2 -RuO 2 Composite coated anode plate, including titanium-clad copper conductive beam, titanium mesh substrate, silicone sleeve, conductive head, the silicone sleeve set is set at the left and right ends of the titanium-clad copper conductive beam, and the bottom end of the titanium-clad copper conductive beam is exposed as copper. Conductive head, the conductive head is connected to an external power supply, and the titanium mesh substrate is fixed at the lower end of the titanium-clad copper conductive beam. The titanium mesh substrate is coated with a gradient Ir-Ta-Sn-SbOx intermediate layer and β-MnO in sequence. 2 -RuO 2 Composite surface active layer; the thickness of the gradient Ir-Ta-Sn-SbOx middle layer is 15µm, β-MnO 2 -RuO 2 The thickness of the composite surface active layer is 150 µm; the titanium mesh substrate 2 is a porous structure with a thickness of 5 mm and a pore diameter of 8 mm;

[0052] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com