High-specific surface area functional active carbon material and electrode slurry preparation method

A high specific surface, electrode slurry technology, applied in battery electrodes, hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of difficulty in dispersion, affecting the capacitance performance of electrode materials, small specific gravity, etc., and achieve particle size distribution. The effect of uniformity, suppression of crystallization unevenness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Pickling, weigh 100Kg activated carbon and add to 1.5m 3 In the enamel reaction kettle, add 0.9t deionized water, stir for 30min, slowly add 45Kg~50Kg nitric acid with a concentration of 0.1mol / L~3mol / L, the solid-liquid ratio is 1:5~20 (weight), stir for 2h~3h, The reactant is repeatedly washed in a plate and frame filter press until the filtrate is neutral;

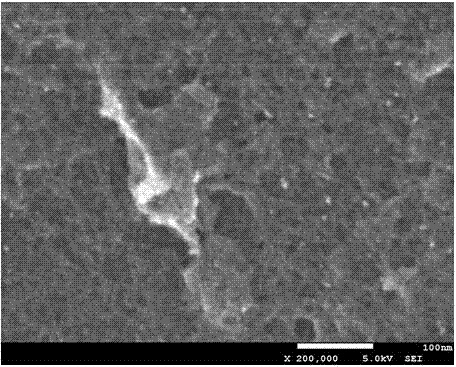

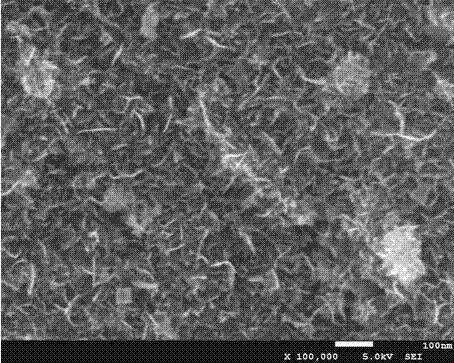

[0047] (2) Surface treatment, put the product in (1) into an enamel reaction kettle with a heating device, add 0.8t deionized water, then add 100Kg urea, and raise the temperature at a rate of 5°C / min~8°C / min , the temperature is controlled between 90 ° C ~ 100 ° C, after constant temperature, stirring for 4 h ~ 6 h, the above reactants are repeatedly washed in the plate and frame filter press until the filtrate is neutral; the surface morphology of the reaction product is as follows figure 1 The surface pores of the treated carbon material are cleaned, and the specific surface area and pore volume and diame...

Embodiment 2

[0055] Steps (1) and (2) are the same as in Example 1;

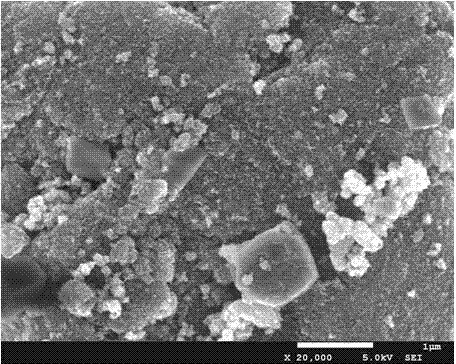

[0056] (3) Loading of oxygen-containing metal compounds, at 1.5m 3 Add 0.9t deionized water, 35Kg nickel nitrate, 2Kg hexadecyltrimethylammonium bromide to the enamel reaction kettle, stir until completely dissolved, add the reactants in (2) to the above enamel reaction kettle, and stir for 0.5 h~1.5h; Measure 25% 22.5Kg concentrated ammonia water and slowly add it to the above-mentioned enamel reaction kettle. less than 5%;

[0057] (4) High temperature oxidation, put the dried product loaded in (3) into an argon-protected resistance furnace, the heating rate is 15°C / min, the constant temperature is 350°C, and the constant temperature oxidation reaction time is 2h;

[0058] (5) For secondary loading of oxygen-containing metal compounds, add 0.9t of deionized water to the enamel reaction kettle, add 36Kg of zinc nitrate, 42Kg of lead sulfate, 20Kg of 5% polyethylene glycol-600 solution, and stir until completely dissol...

Embodiment 3

[0062] Same as Example 1, but nitric acid in (1) is changed to phosphoric acid, and the others remain unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com