A continuous autoclave method

A technology of autoclaving and autoclaving, which is applied to conveyor objects, furnaces, packaging, etc., can solve problems such as low energy utilization efficiency, low efficiency, and reduced production efficiency, and achieve the effect of improving production efficiency and energy utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

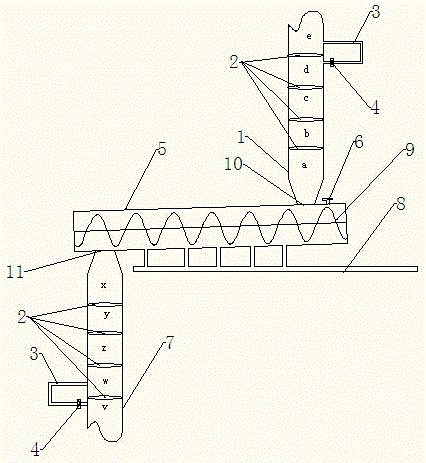

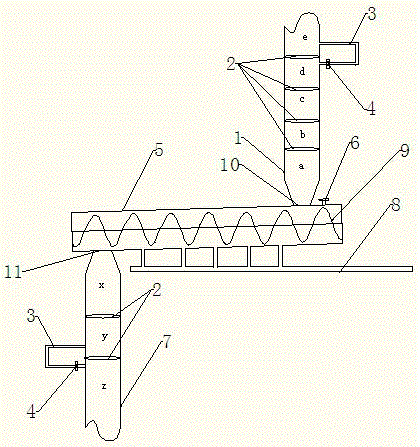

[0024] The continuous autoclaving device of the present invention includes a pressure cylinder 5, and also includes a vertical cylinder-shaped feed bin 1 and a discharge bin 7 respectively. 1 There is a feed port 10 at the corresponding position, and the lower part of the feed bin 1 is connected with the pressure cylinder 5 through the feed port 10; 5 There is a discharge port 11 at the position corresponding to the discharge bin 7, and the upper part of the discharge bin 7 is connected with the pressure cylinder 5 through the discharge port 11;

[0025] There is an auger 9 inside the pressure cylinder 5 as a pushing device, which continuously stirs, turns and pushes the material released from the feed bin 1 to the pressure cylinder 5, and improves the steam pressure efficiency of the material.

[0026] There are four valve bodies 2 in the feed bin 1 and the discharge bin 7, and the 4 valve bodies 2 in the feed bin 1 are arranged in order from top to bottom. The valve body 2 c...

Embodiment 2

[0039] The difference from Embodiment 1 is that the discharge bin is set as three bin units of x, y, and z, and its operation principle is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com