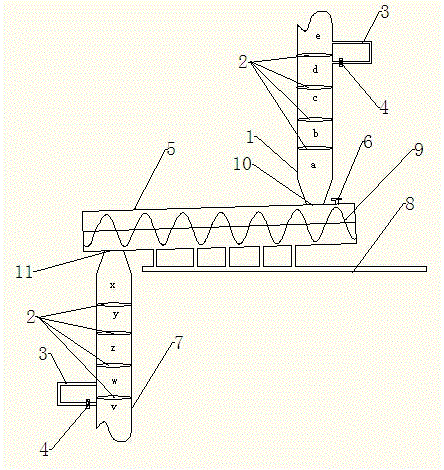

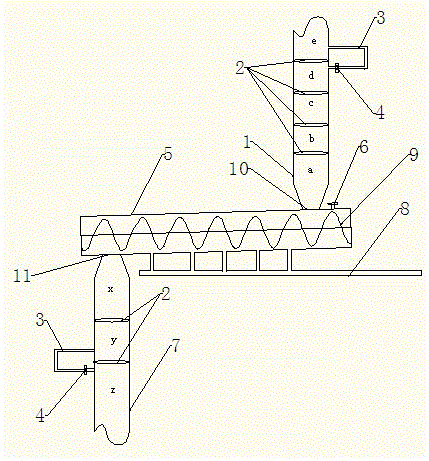

Sandy soil conditioner and continuous steam-pressing device and method thereof

A technology of soil conditioner and autoclave device, applied in fertilization device, fertilizer mixture, application and other directions, can solve the problems of unstable effect, reduced production efficiency, large pressure loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] The sandy soil conditioner comprises the following components in parts by weight:

[0111] Polyacrylamide 11.46

[0112]Carboxymethylcellulose 7.59

[0113] Furfural residue 13.58

[0114] Peat 16.84

[0115] Bentonite 19.22

[0116] stick clay 12.15

[0117] Boron magnesium powder 6.54

[0118] Straw powder 18.49

[0119] Biogas residue 11.91

[0120] Humic acid 13.86

[0121] Trace elements 0.87.

[0122] The trace elements are: a mixture of boric acid, borax, zinc sulfate, copper sulfate, manganese sulfate, and ammonium molybdate, and the weights of boric acid, borax, zinc sulfate, copper sulfate, manganese sulfate, and ammonium molybdate are all the same.

[0123] Choose three lands with the same soil quality and close proximity, and the common characteristics of the three lands are sandy soil. The soil has more sand and less mud, and the structure is poor; it leaks water and fertilizer, and is prone to drought; the soil is barren and has low nutrient conte...

Embodiment 2

[0131] The sandy soil conditioner comprises the following components in parts by weight:

[0132] Polyacrylamide 8

[0133] Carboxymethyl cellulose 4

[0134] Furfural residue 8

[0135] Peat 14

[0136] Bentonite 12

[0137] stick clay 6

[0138] Boron magnesium powder 3

[0139] straw powder 12

[0140] Biogas residue 6

[0141] Humic acid 8

[0142] Trace elements 0.3.

[0143] The trace elements are: a mixture of boric acid, borax, zinc sulfate, copper sulfate, manganese sulfate, and ammonium molybdate, and the weights of boric acid, borax, zinc sulfate, copper sulfate, manganese sulfate, and ammonium molybdate are all the same.

Embodiment 3

[0145] The sandy soil conditioner comprises the following components in parts by weight:

[0146] Polyacrylamide 15

[0147] Carboxymethylcellulose 10

[0148] Furfural residue 20

[0149] Peat 22

[0150] Bentonite 25

[0151] stick clay 18

[0152] Boron magnesium powder 12

[0153] straw powder 25

[0154] Biogas residue 18

[0155] Humic Acid 19

[0156] Trace elements 1.5.

[0157] The trace element is a mixture of zinc sulfate, copper sulfate and manganese sulfate, and the weight of the three is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com