Low-addition-amount environment-friendly alkali-free chlorine liquid accelerator and preparation method thereof

A kind of quick-setting agent and green technology, which is applied in the field of low-dosage green alkali-free chlorine liquid quick-setting agent and its preparation, can solve the problems of high alkali content of liquid quick-setting agent, large strength loss at 28 days, poor stability period, etc., and achieve Rapid preparation, reduced energy consumption, and no loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

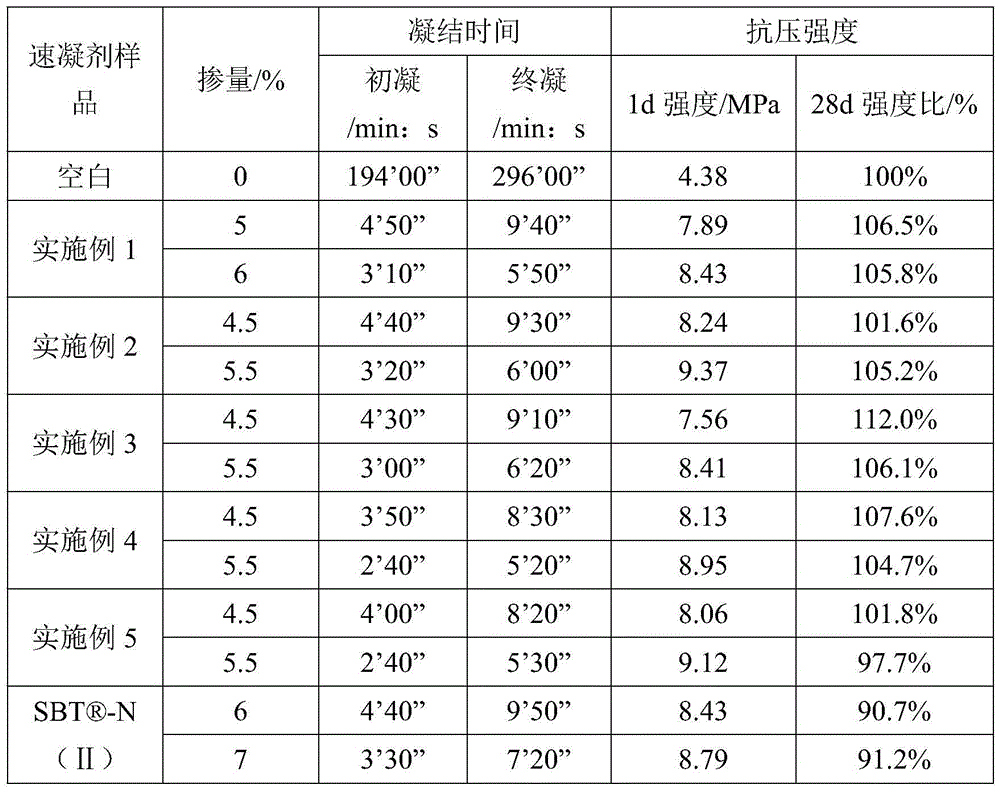

Embodiment 1

[0033] Low-volume green alkali-free chlorine liquid quick-setting agent, including the following components in mass percentage: aluminum sulfate: 45%, magnesium sulfate 8%, diethanolamine 10%, formic acid 5%, polyacrylic acid 5%, citric acid 1%, Tap water: 26%.

[0034] The preparation method of this low-volume non-alkali chlorine liquid quick-setting agent:

[0035] Add tap water into a water bath container and heat to 60°C; gradually add aluminum sulfate under continuous stirring until it dissolves into a suspension of small particles; add stabilizer and keep the temperature at 60°C for 15 minutes; slowly add alcohol amine, and stir at constant temperature until the sulfuric acid All aluminum is dissolved into a clear and transparent solution; magnesium sulfate is added and stirred until completely dissolved; organic acid and high molecular polymer are added and stirred until the solution is cooled to room temperature to obtain a low-volume green alkali-free liquid accelerat...

Embodiment 2

[0037] Low-volume green non-alkali chlorine liquid quick-setting agent, including the following components in mass percentage: aluminum sulfate: 50%, magnesium sulfate 6%, triethanolamine 9%, benzoic acid 2%, polyacrylamide 2%, citric acid 3% %, tap water: 28%.

[0038] Heat the water to 55°C; add aluminum sulfate under continuous stirring until it dissolves into a suspension of small particles; add stabilizer and keep the temperature at 55°C for 20 minutes; slowly add alcohol amine, stir at 55°C until the aluminum sulfate is completely dissolved To clarify the transparent solution, stop heating; add magnesium sulfate, stir until completely dissolved; add organic acid and high molecular polymer, stir until the solution is cooled to room temperature, and obtain a low-volume green alkali-free liquid accelerator.

Embodiment 3

[0040] Low-volume green alkali-free chlorine liquid quick-setting agent, including the following components in mass percentage: aluminum sulfate: 50%, magnesium sulfate 10%, diethanolamine 5%, oxalic acid 1%, polyacrylic acid 4%, tap water: 30% %.

[0041] Heat the water to 65°C; add aluminum sulfate under continuous stirring until it dissolves into a suspension of small particles; add stabilizer and keep the temperature at 65°C for 15-20min; slowly add alcohol amine, stir at 65°C until aluminum sulfate All dissolve into a clear and transparent solution, stop heating; add magnesium sulfate, stir until completely dissolved; add organic acid and high molecular polymer, stir until the solution is cooled to room temperature, and obtain a low-volume green alkali-free liquid accelerator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com