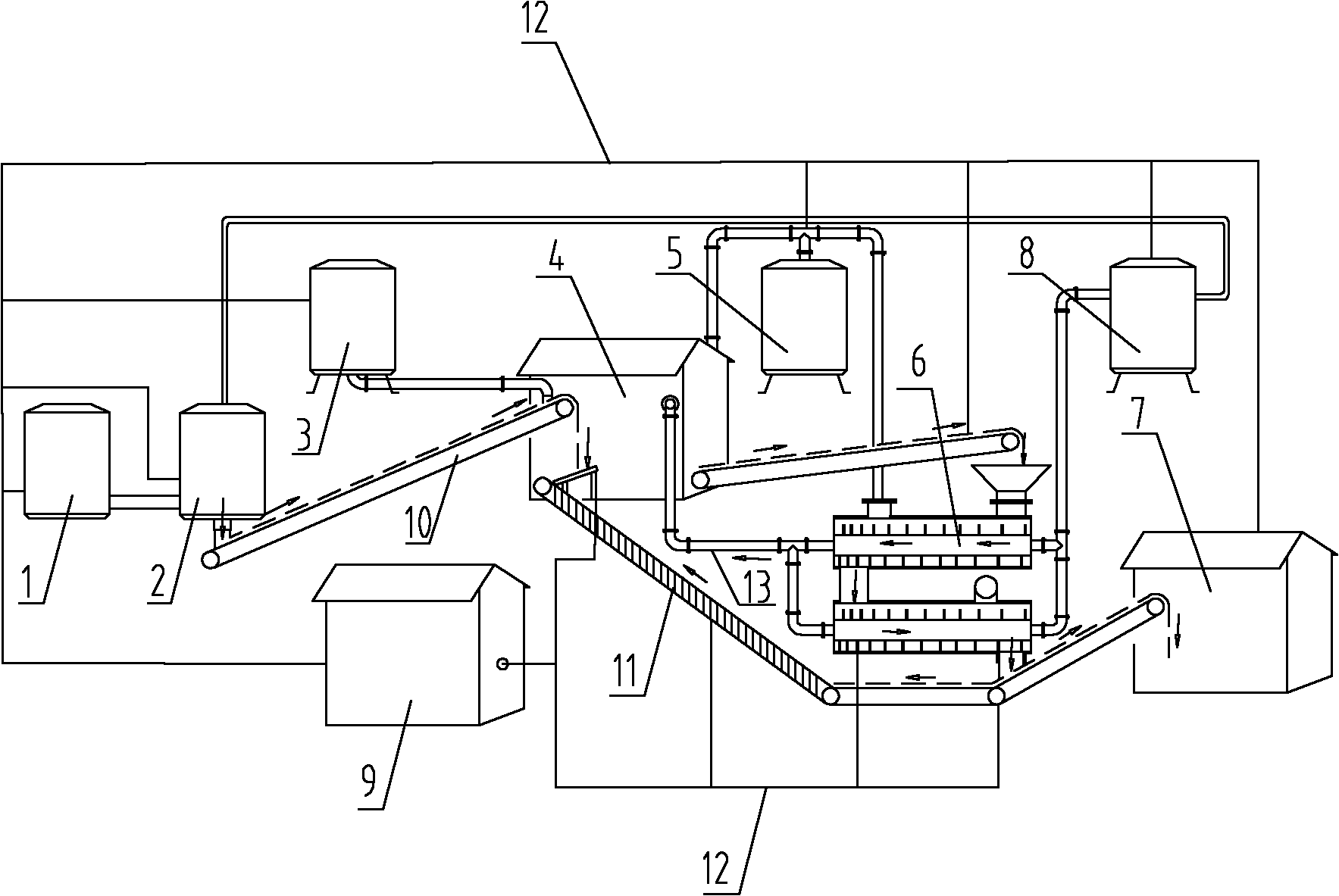

Sludge dehydrating and drying process method and device

A sludge dehydration and process method technology, applied in the field of environmental engineering, can solve the problems of high cost of polymer conditioner polyacrylamide, unfavorable secondary dehydration and drying treatment of sludge, and negative impact on the performance of lightweight brick blocks. Achieve the effect of streamlined equipment, low cost and strict management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

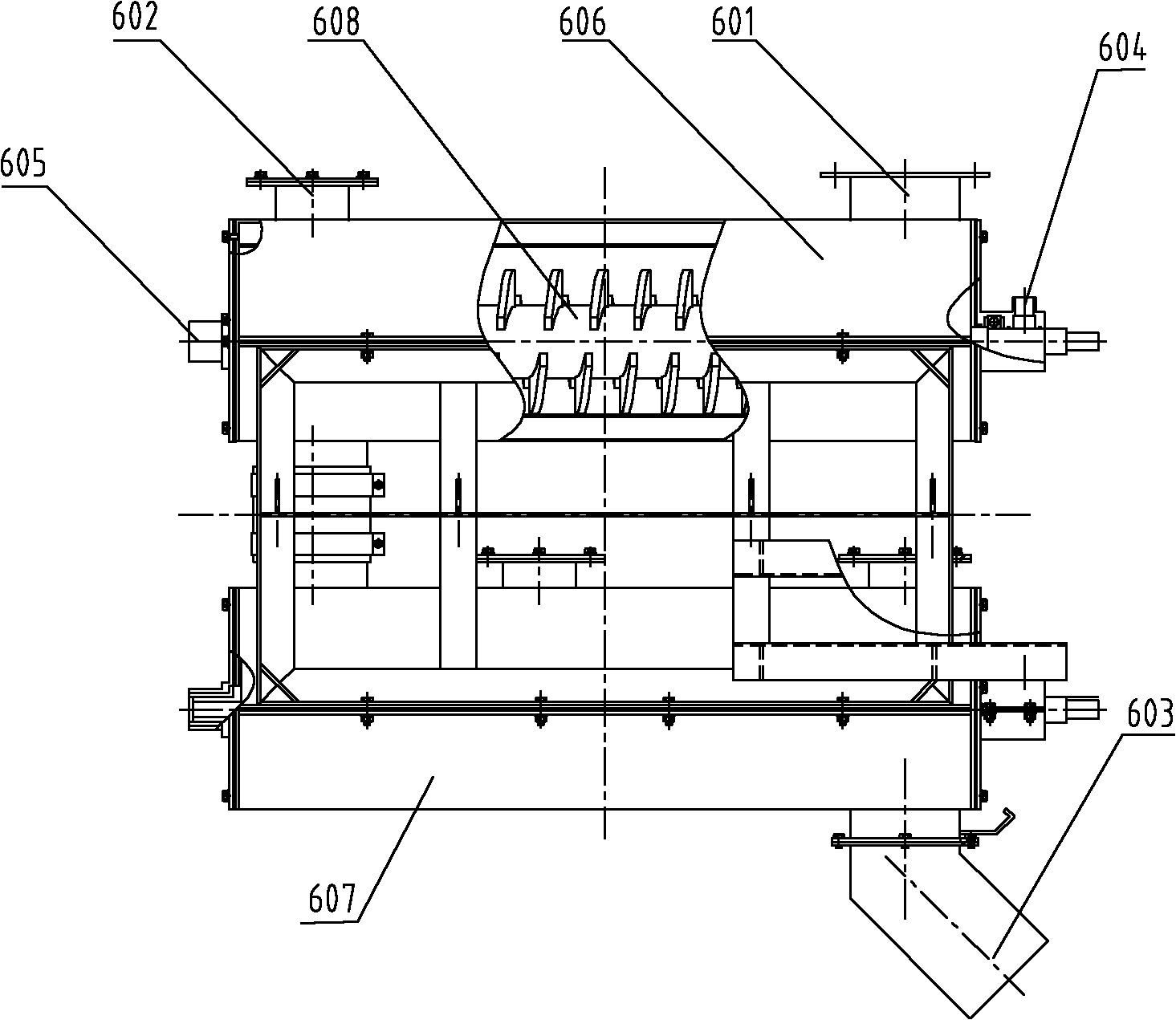

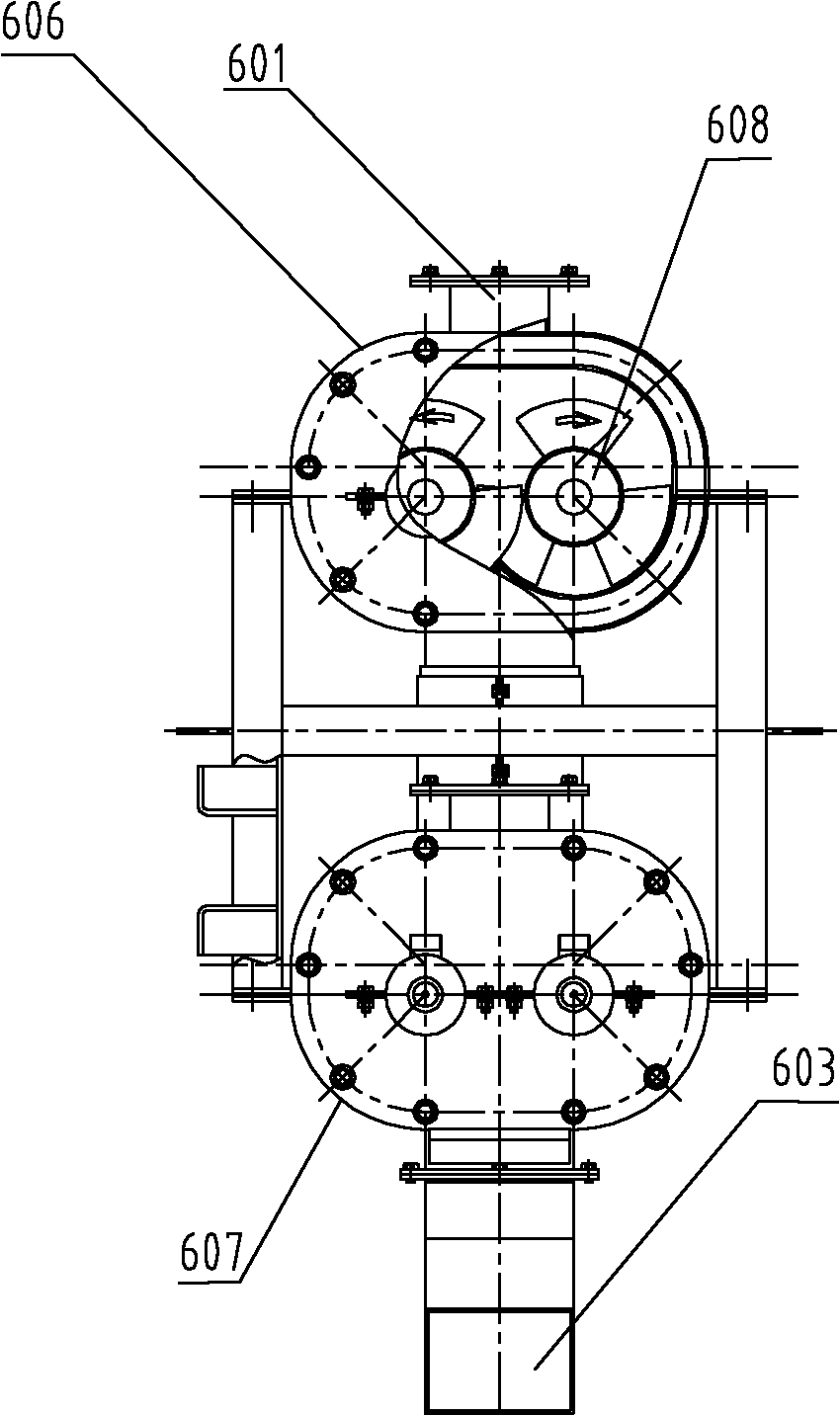

[0049] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0050] Firstly, the present invention conducts a preliminary sludge removal and dehydration conditioning test, and the sludge specific resistance and the water content of the dewatered mud cake are used as indicators to measure the sludge dehydration effect.

[0051] Traditional sludge dewatering uses organic coagulants for dehydration, organic coagulants (such as PAM, etc.) have better initial dehydration effects, but the cost of polymer conditioner polyacrylamide (PAM) is higher, and the addition of PAM conditioning The mud cake after sludge dehydration appears sticky, which is not conducive to the secondary dehydration and drying treatment of sludge. The most important thing is that the sludge added with PAM has a negative impact on the performance of making lightweight brick blocks. Therefore, it is necessary to find an economical and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com