Preparation method of coated iron oxide black with medium temperature resistance

An iron oxide black, warm-coated technology, used in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of poor high temperature resistance of iron oxide black, and achieve short treatment process and dispersion performance. Superior, easy-to-operate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

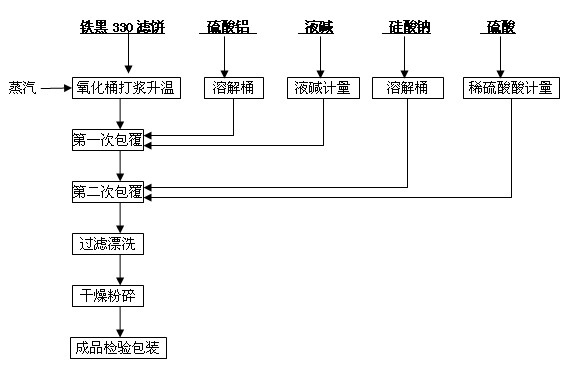

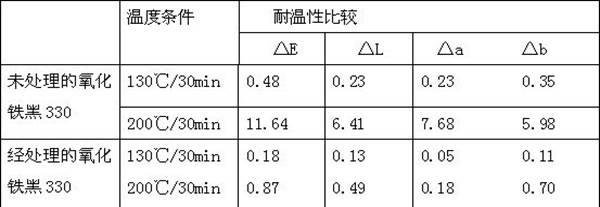

[0029] Such as figure 1 As shown, take 1 ton of iron oxide black filter cake, with a solid content of 60% and beat the temperature to 85-95 degrees. Add the auxiliary agent aluminum sulfate to 18% of the converted dry powder amount. Minutes, use 20-40% liquid caustic soda to adjust the pH to 9.5 and let it stir for 90 minutes. Calculate the amount of sodium silicate added, which is 25% of the dry powder amount. The actual amount added is 150 kg, and the beating reaction is continued for 30 minutes. Minutes, adjust the pH to be neutral with 10-20% dilute sulfuric acid, let it stir and react for 90 minutes. Rinse and tumble dry. The comparison of the test results between the medium temperature resistant iron oxide black produced by this process and ordinary iron oxide black is as follows:

[0030]

Embodiment 2

[0032] Such as figure 1 As shown, take 1 ton of iron oxide black filter cake, with a solid content of 60% and beat the temperature to 85-95 degrees. Add the auxiliary agent aluminum sulfate to 25% of the converted dry powder amount. Minutes, use 20-40% liquid alkali to adjust the pH to 9.5 and let it stir for 90 minutes. Calculate the amount of sodium silicate added, which is 20% of the dry powder amount. The actual amount added is 120 kg, and the beating reaction is continued for 30 minutes. Minutes, adjust the pH to be neutral with 10-20% dilute sulfuric acid, let it stir and react for 90 minutes. Rinse and tumble dry. The comparison of the test results between the medium temperature resistant iron oxide black produced by this process and ordinary iron oxide black is as follows:

[0033]

[0034] From the above comparison results, the temperature resistance of the coated iron oxide black pigment changes at about 200 degrees, and the ΔE is below 1.0, while the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com