Metal ferrochromium preparing method by computer-controlled double microwave ovens

A computer and metal chromium technology, which is applied in the field of preparing metal ferrochromium in microwave double furnaces, can solve the problems of imperfect preparation process, low yield, failure to achieve programming and automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

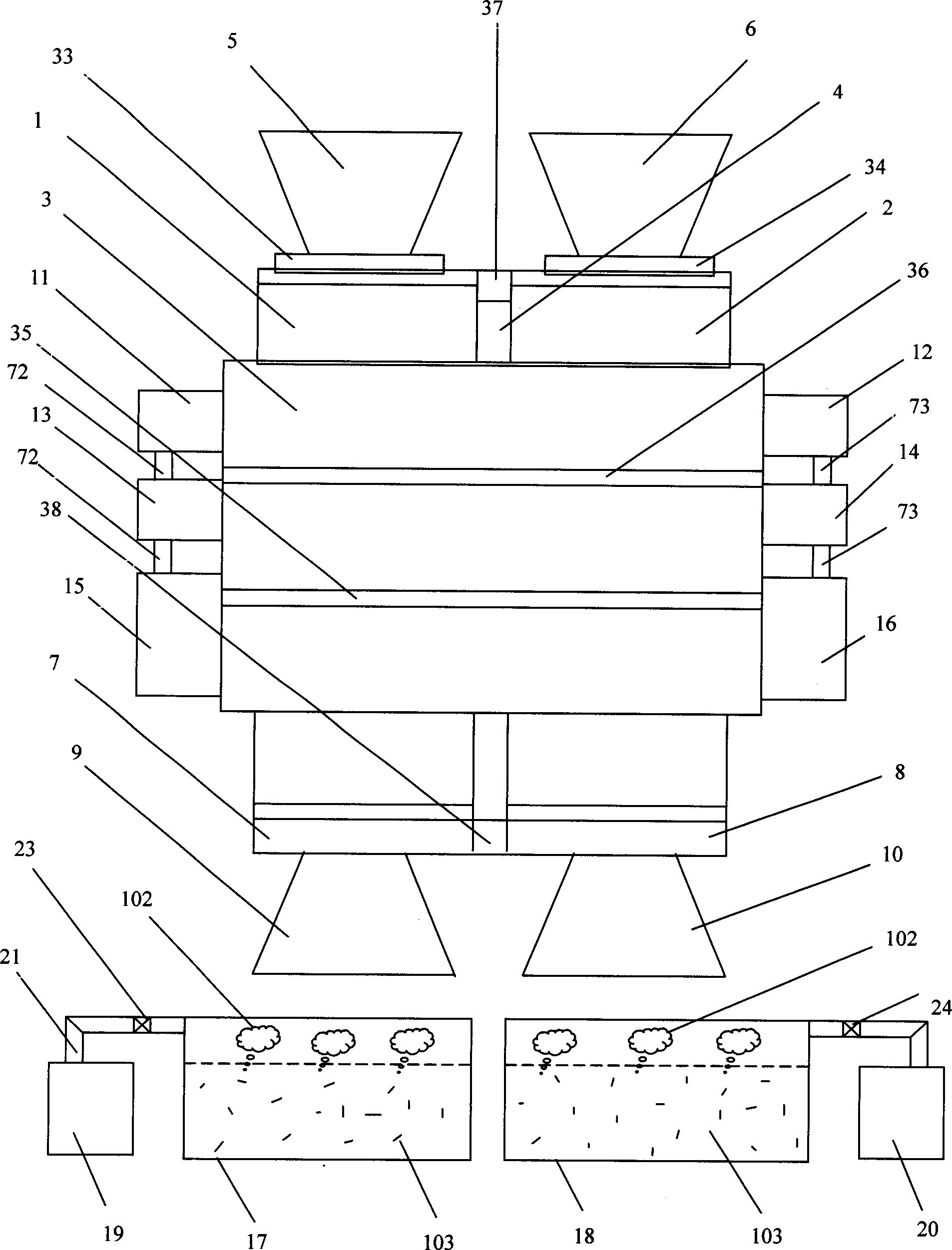

[0102] All production equipment is in ready working condition;

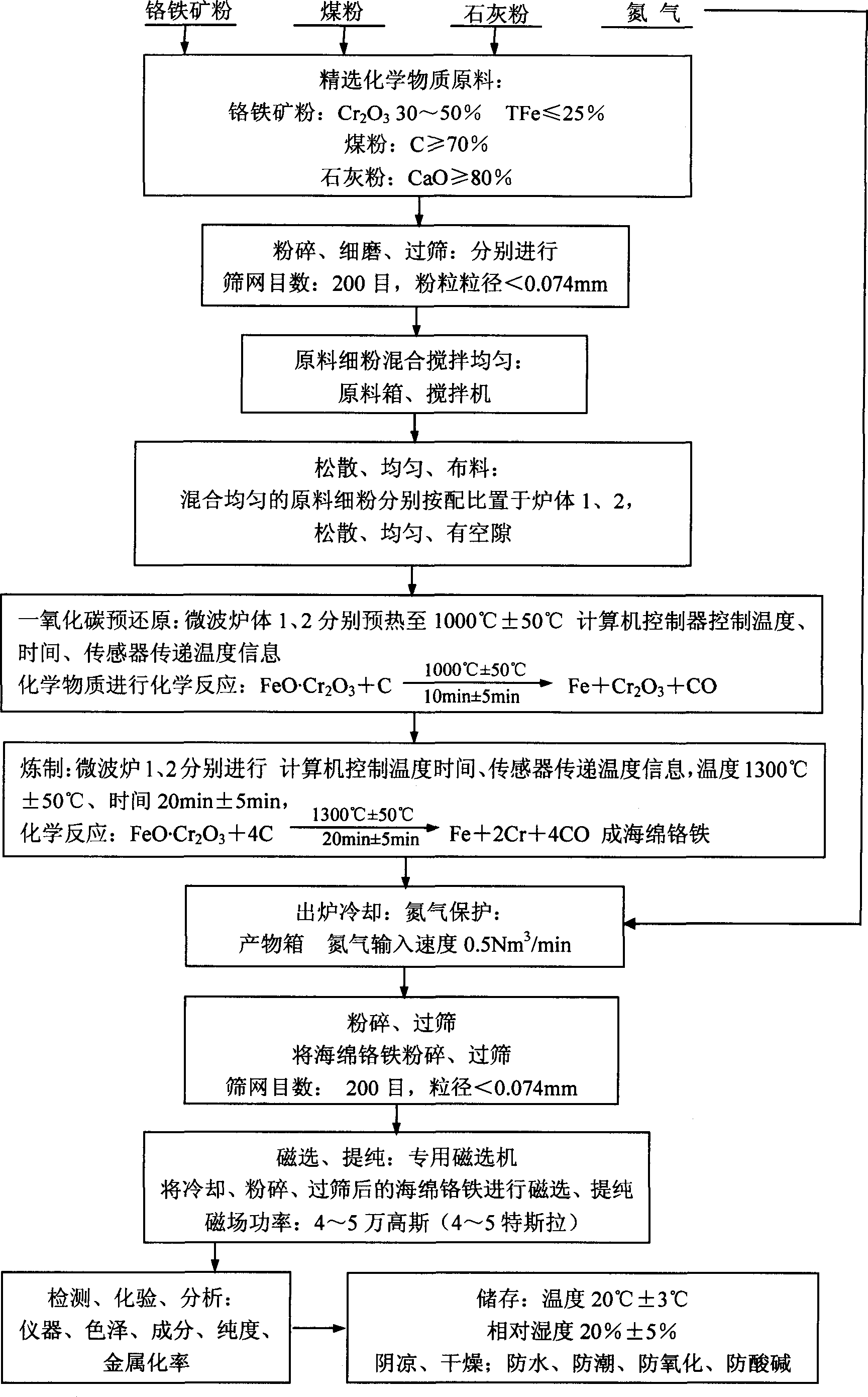

[0103] Featured and weighed 70 parts by weight of chromite powder, 17 parts by weight of pulverized coal, and 10 parts by weight of lime powder;

[0104] Crush, finely grind, and sieve the fine powder of raw materials to control the fineness, the mesh number of the screen is 200 mesh, and the particle size of each raw material powder is <0.074mm;

[0105] Mix well;

[0106] Open the left and right furnace body to loosen the material naturally;

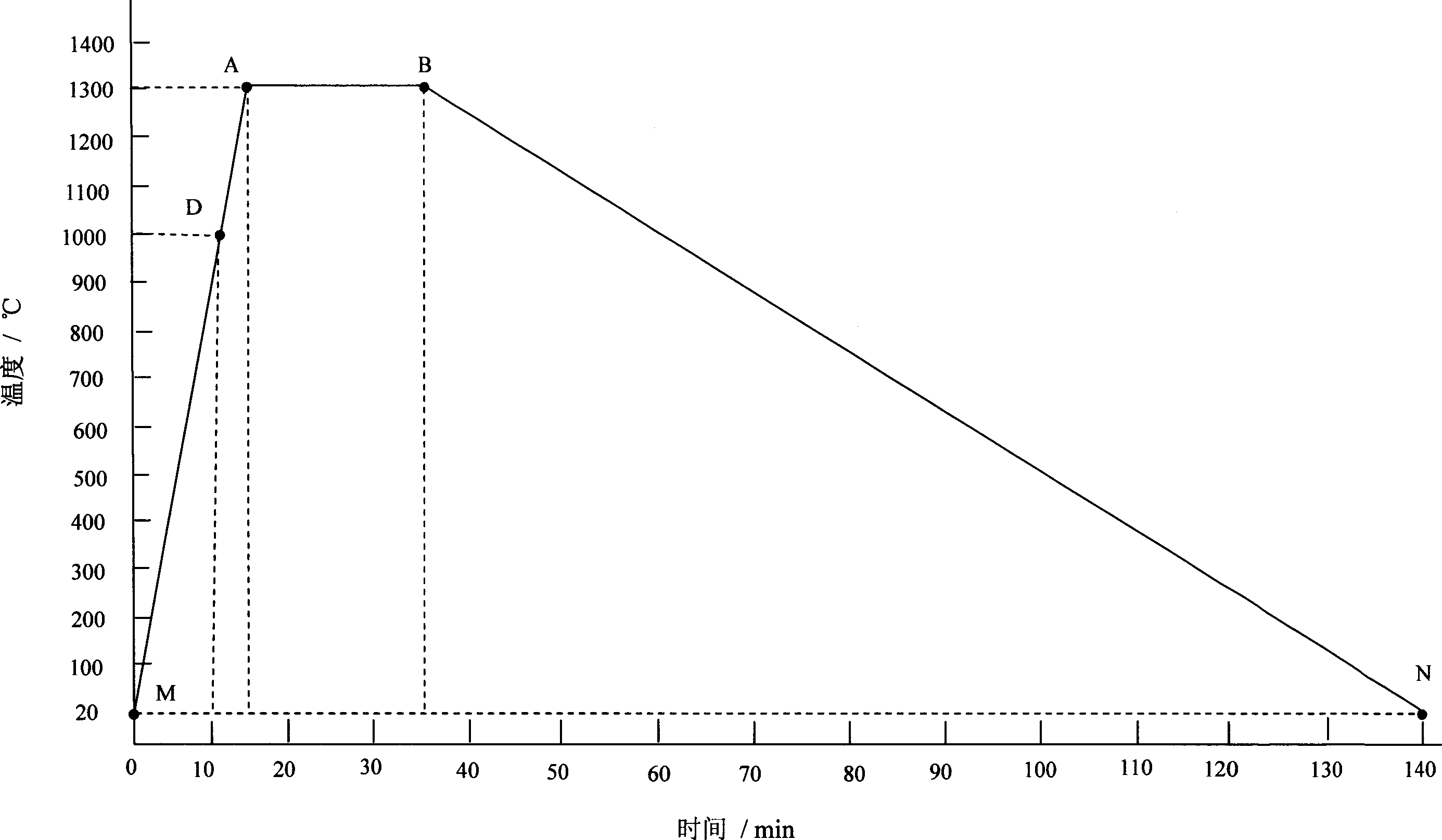

[0107] Close the left and right furnaces, preheat the left and right furnaces to 1000°C±50°C, preheat for 10min±5min, computer controls the microwave heating temperature, and pre-reduces carbon monoxide;

[0108] Refined products: the computer controller controls the temperature of the left and right furnaces to 1300°C±50°C, keeps the temperature at a constant temperature for 20min±5min, chemical reaction, refining metal ferrochrome;

[0109] Open the left and right fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com