Composite support anchor rod and construction method thereof

A composite support and bolt technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of cracking and falling off of the spray layer, small shrinkability, poor flexibility, etc., and achieve less equipment and wide application , cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

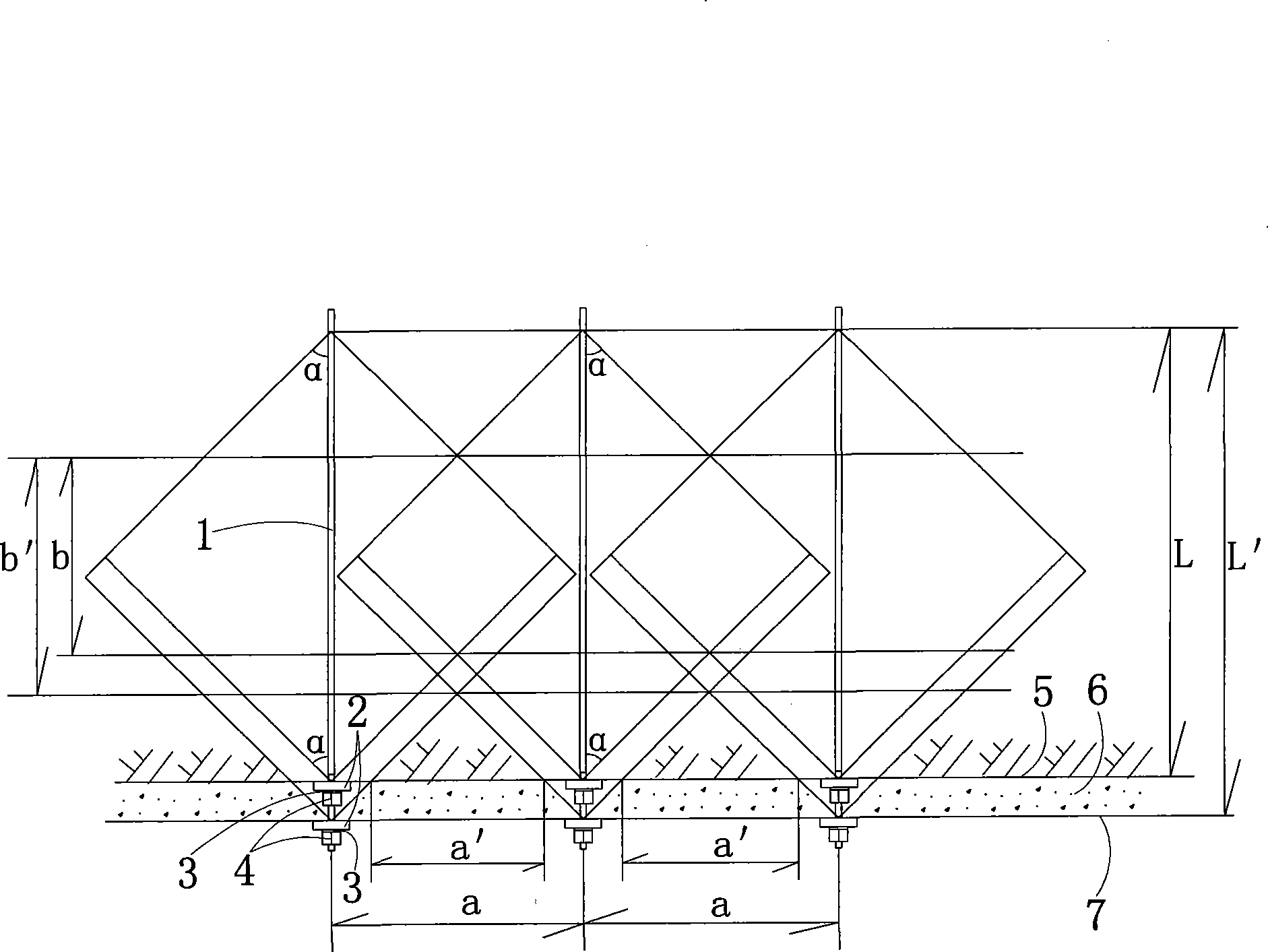

[0026] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings:

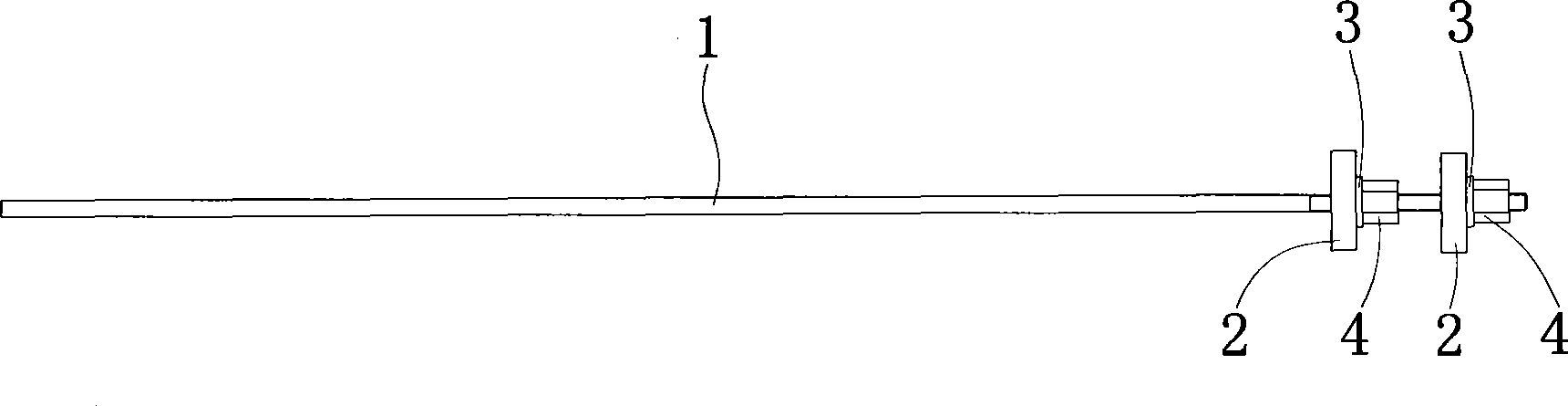

[0027] see figure 1 , the anchor rod has a rod body 1 with external threads on one side, two sets of compression parts arranged on the rod body 1, each set of compression parts includes a tray 2 socketed with the rod body 1, screwed with the rod body 1 and close to the external thread For the nut 4 at the outer end, a washer 3 is set on the rod body 1 corresponding to the space between the tray 2 and the nut 4 in each set of pressing parts, and the length of the external thread is 200mm.

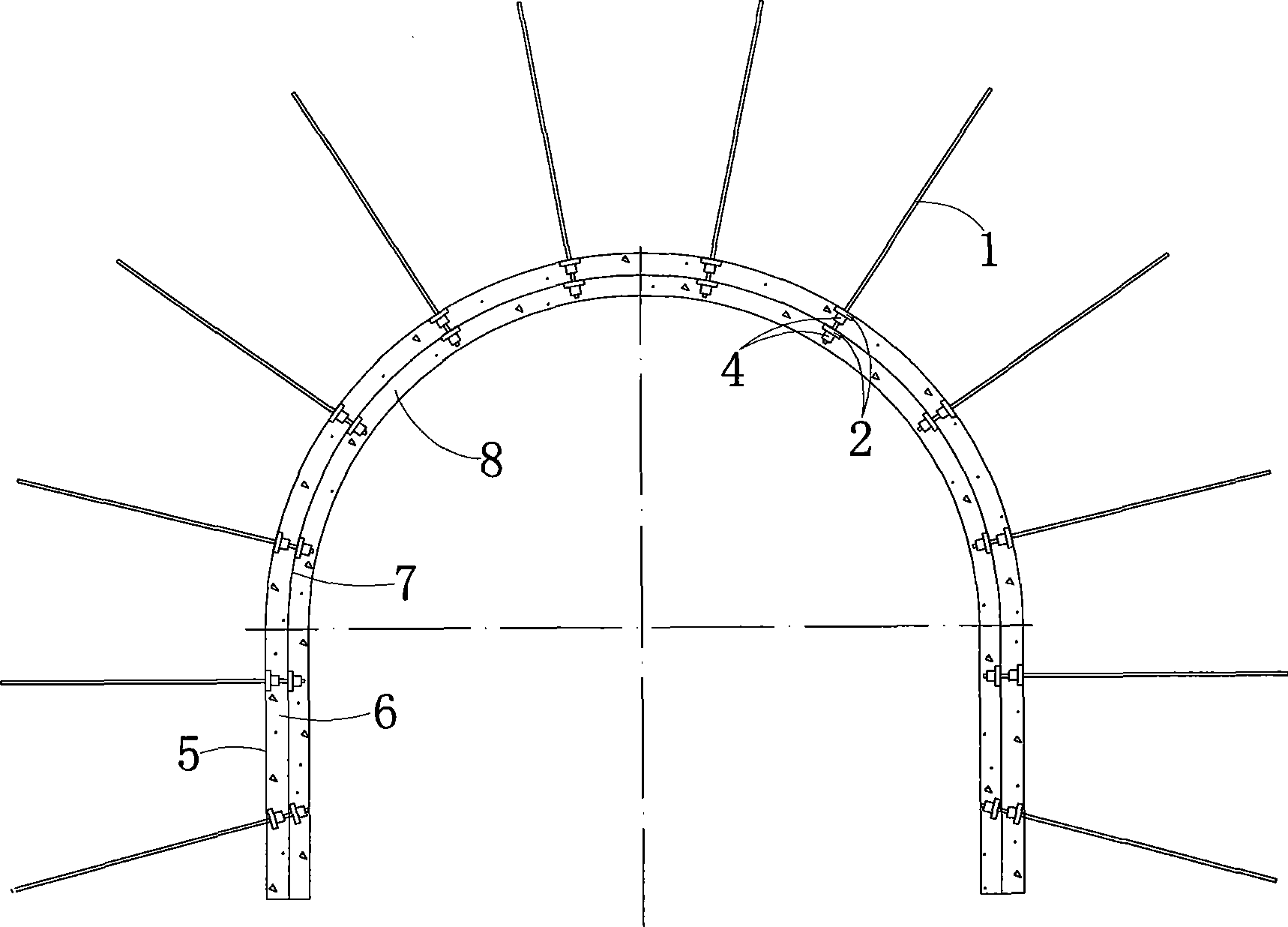

[0028] see figure 2 , the construction method of the bolt, it comprises the following process steps:

[0029] (1) Rock breaking: By blasting or mechanical means, the surrounding rock is broken to the design section size ( figure 2 The surrounding rock is not shown in the figure);

[0030] (2) Anchor hole positioning and hole formation: pre-drill anchor holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com