Method for preparing inorganic compound gallium nitride nanowire

A technology of gallium nitride nanowires and inorganic compounds, which is applied in the direction of inorganic chemistry, chemical instruments and methods, gallium/indium/thallium compounds, etc., which can solve the difficulties in the growth process, the unsatisfactory product morphology, and the wide application of unfavorable products, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

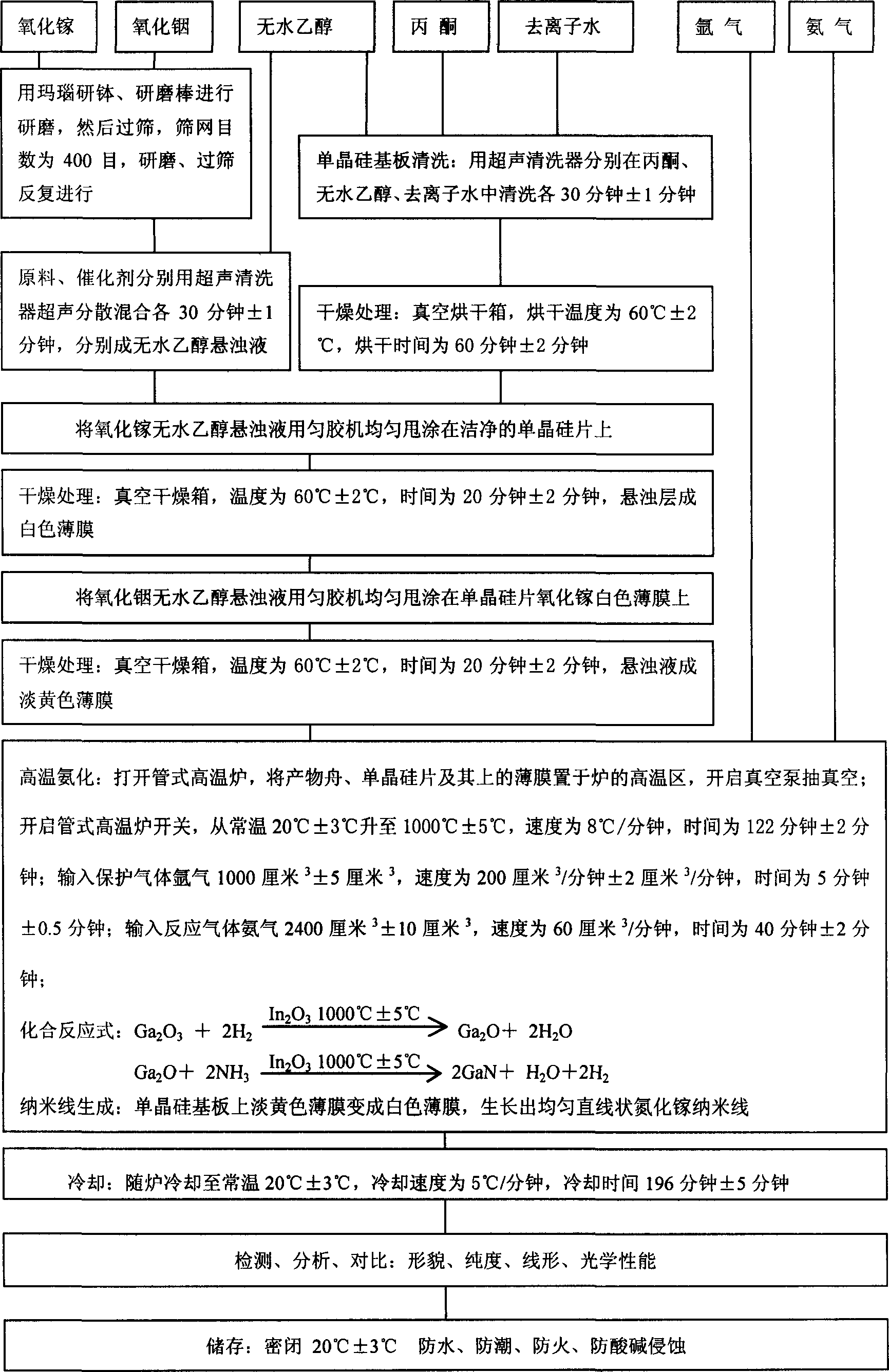

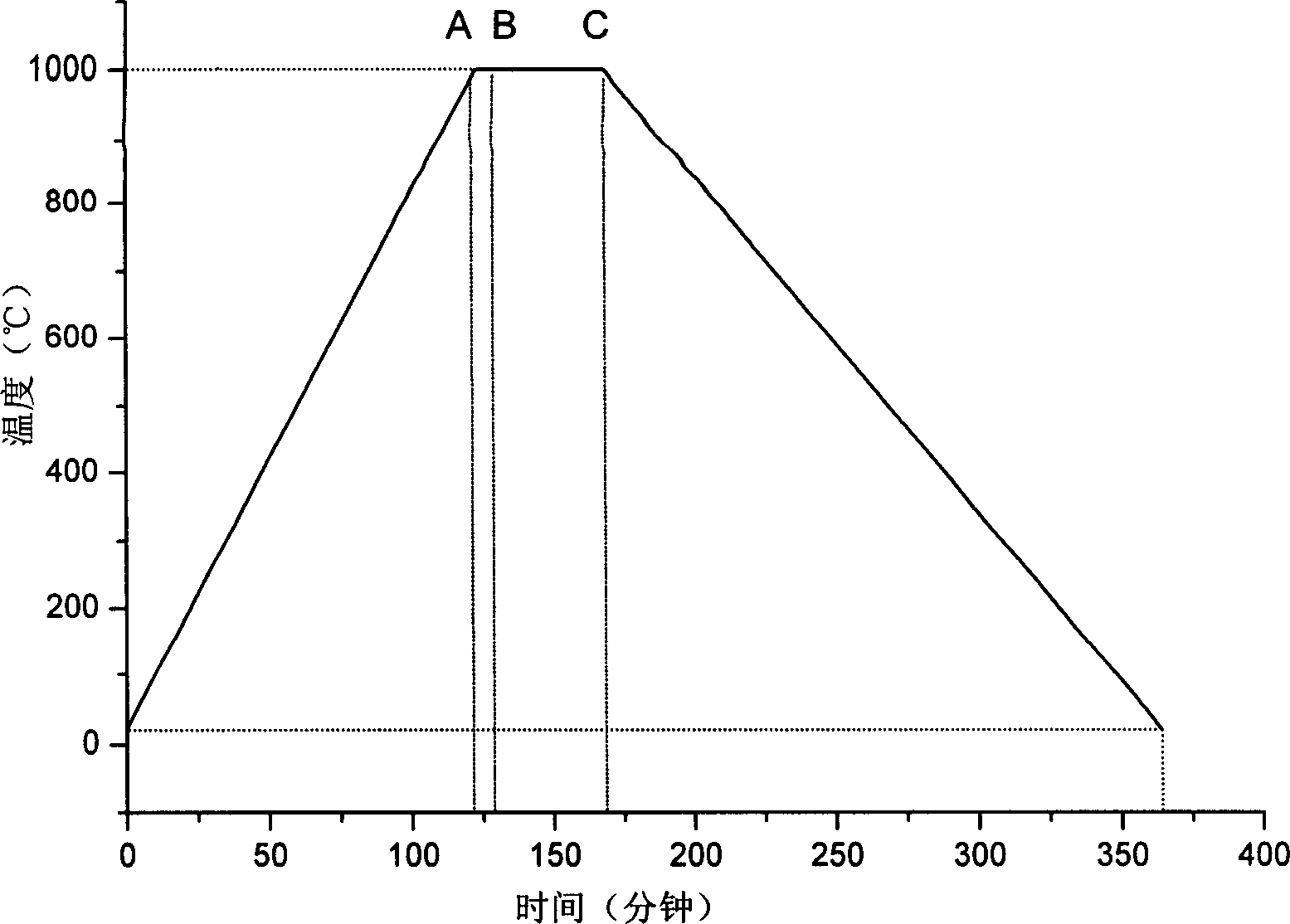

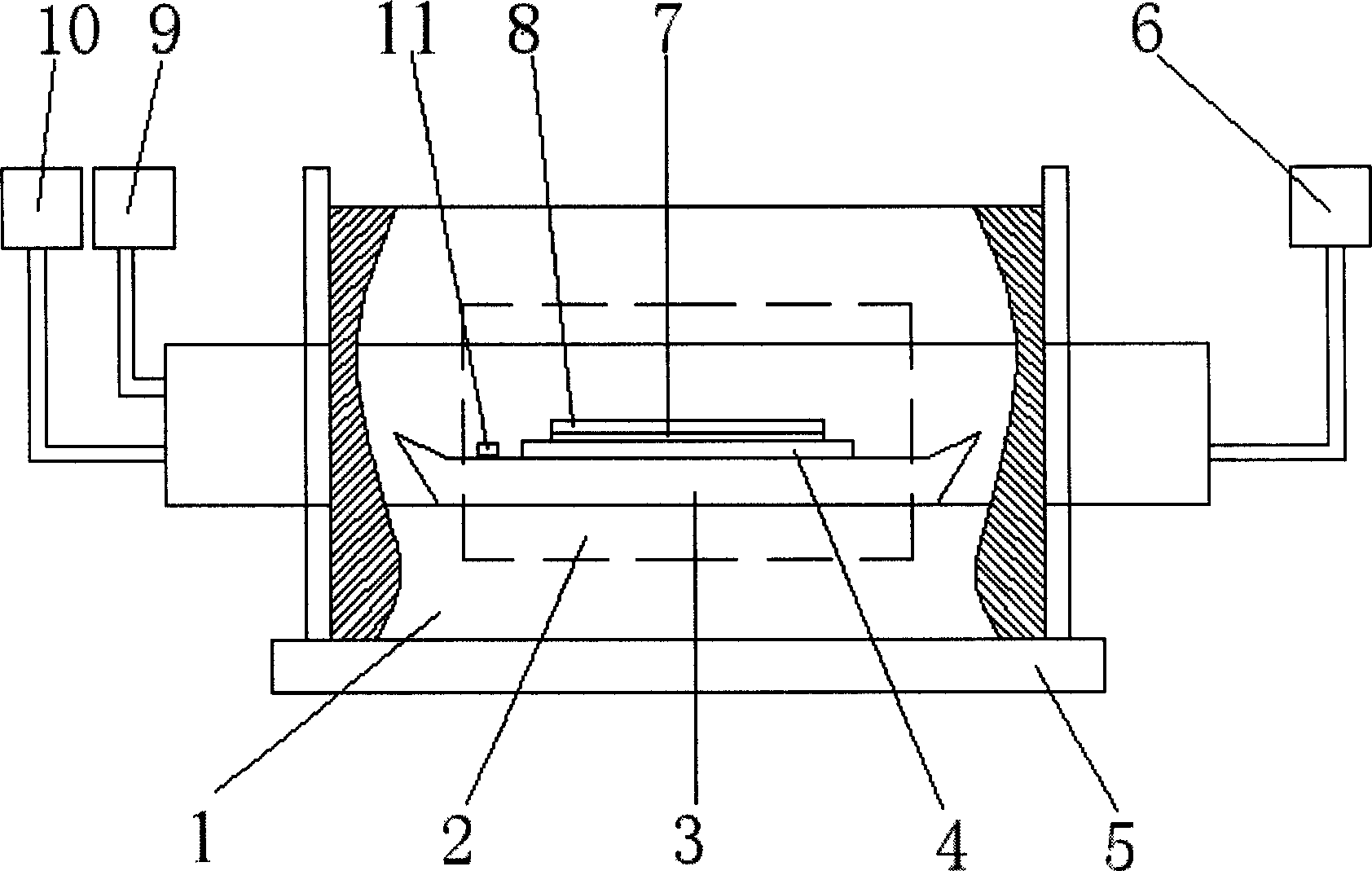

[0100] All production equipment are in quasi-working condition;

[0101] Weigh and weigh 0.5 grams of gallium oxide, 0.2 grams of indium oxide, 5 milliliters of acetone, 15 milliliters of absolute ethanol, and 2400 cm of ammonia gas according to the proportion 3 , Argon 1000 cm 3 , 10 ml of deionized water;

[0102] Grinding and sieving: Repeatedly grinding and sieving gallium oxide and indium oxide respectively into fine powder, the sieve is 400 mesh;

[0103] Ultrasonic cleaning of the monocrystalline silicon substrate: the cleaning agent is 5 ml of acetone, 5 ml of absolute ethanol, and 10 ml of deionized water, and ultrasonic cleaning is performed for 30 minutes each with an ultrasonic cleaner;

[0104] Drying: Dry in a vacuum drying oven for 60 minutes ± 2 minutes, and the drying temperature is 60°C ± 2°C;

[0105] Ultrasonic dispersion and mixing: Disperse and mix 0.2 g of gallium oxide and 0.2 g of indium oxide in 5 ml of absolute ethanol respectively, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com