Low-energy drying treatment method for discharged sludge

A treatment method and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

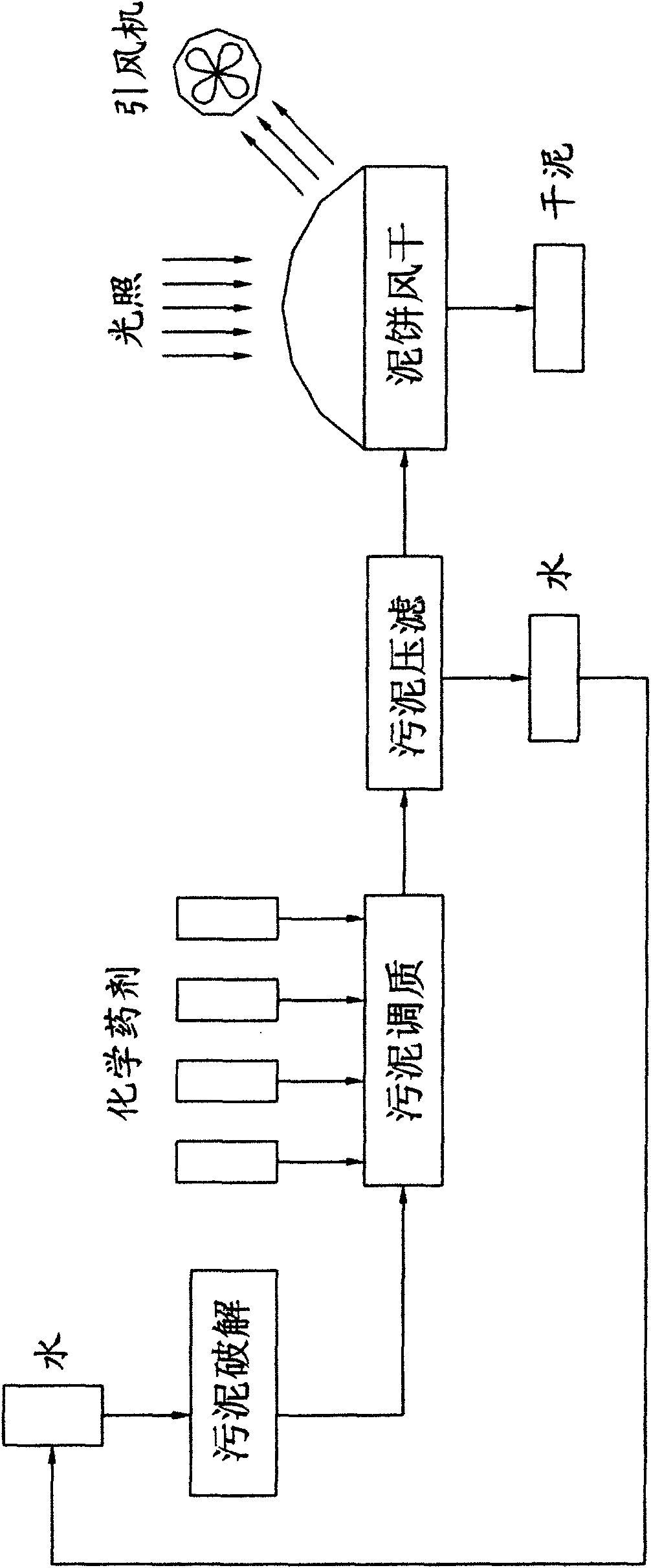

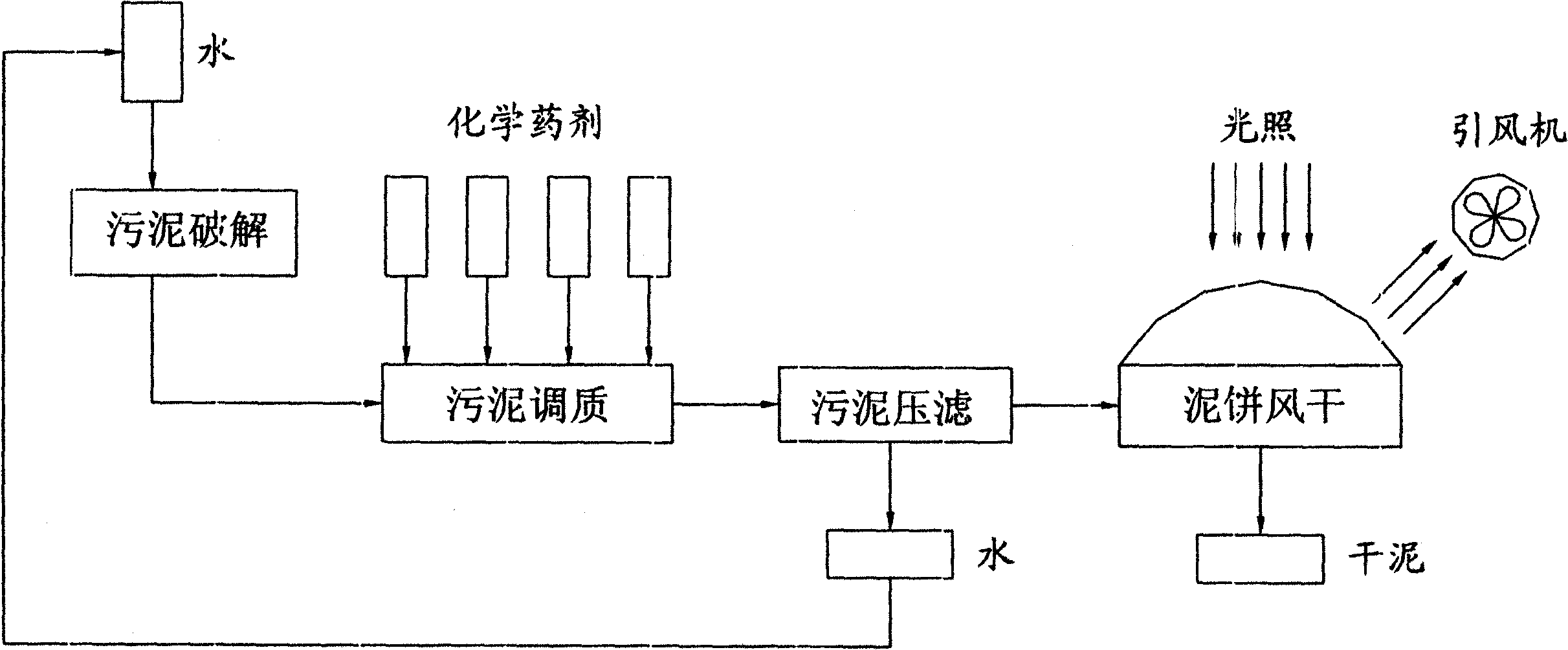

[0027] Such as figure 1 As shown, the sludge treatment method of the present invention reduces the water content of 80% of the factory sludge to 20-30% in four steps, and makes mud cakes.

[0028] The first step: the physical cracking process is realized through the following scheme:

[0029] Mix the sludge and water in the first reaction tank with a weight ratio of 1:0.6 to 1.2 for 6 to 20 minutes, and the rotation speed is 120 rpm. Stir in the middle spiral for 6 minutes, or in the first reaction tank at a weight ratio of 1:1 for 10 minutes, or in the reaction tank at a weight ratio of 1:1.2 for 20 minutes, the amount of water to be added is mainly determined according to the composition of the sludge Specific gravity and stirring time;

[0030] The second step: chemical conditioning and modification process, the sludge that has undergone physical cracking in the first step is sent to the second reaction tank to add the following chemicals:

[0031] (a) PH value adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com