Preparation method of in-situ quaternized antibacterial agent on surface of carbon nano tube

A technology of carbon nanotubes and acidified carbon nanotubes, which is applied in the directions of biocide-containing paint, rayon manufacturing, fiber chemical characteristics, etc., can solve the problems of harsh reaction conditions, complex chemical reactions, etc. Safe, good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

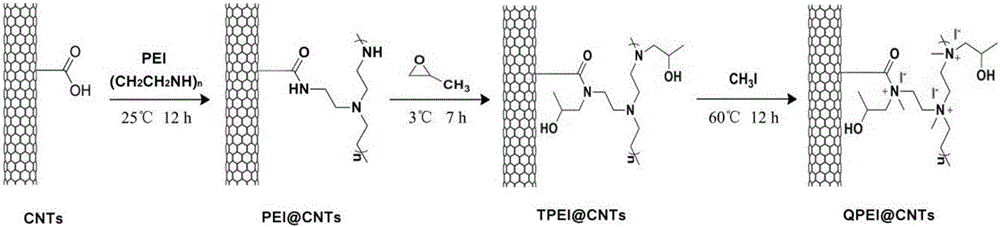

[0029] (1) Carbon nanotube grafted polyethyleneimine: disperse acidified carbon nanotubes and polyethyleneimine with a molecular weight of 70000 (mass ratio of carbon nanotubes to polyethyleneimine 1:3) in deionized water, Then mix, ultrasonic treatment for 1 hour, the power is 250W, make it evenly dispersed, and stir at room temperature for 12 hours, so that polyethyleneimine and acidified carbon nanotubes fully react, the solid product obtained from the reaction is washed with ethanol and water in turn, and suction filtered After separation, polyethyleneimine-grafted carbon nanotubes are obtained.

[0030] (2) Tertiary amination reaction: disperse the carbon nanotube grafted polyethyleneimine prepared in step (1) in deionized water, stir evenly, according to the mass ratio of propylene oxide and polyethyleneimine is 5:3 Proportioning, the tertiary amination reagent propylene oxide is slowly added dropwise to the dispersion liquid, stirred and reacted at 3°C for 7 hours, th...

Embodiment 2

[0033] (1) Carbon nanotube grafted polyethyleneimine: disperse acidified carbon nanotubes and polyethyleneimine with a molecular weight of 600 (mass ratio of carbon nanotubes to polyethyleneimine 1:3) in deionized water, Then mix, ultrasonic treatment for 1 hour, the power is 250W, make it evenly dispersed, and stir at room temperature for 12 hours, so that polyethyleneimine and acidified carbon nanotubes fully react, the solid product obtained from the reaction is washed with ethanol and water in turn, and suction filtered After separation, polyethyleneimine-grafted carbon nanotubes are obtained.

[0034] (2) Tertiary amination reaction: disperse the carbon nanotube grafted polyethyleneimine prepared in step (1) in deionized water, stir evenly, according to the mass ratio of propylene oxide and polyethyleneimine is 5:3 Proportioning, the tertiary amination reagent propylene oxide is slowly added dropwise to the dispersion liquid, stirred and reacted at 3°C for 7 hours, the ...

Embodiment 3

[0037] (1) Carbon nanotube grafted polyethyleneimine: disperse acidified carbon nanotubes and polyethyleneimine with a molecular weight of 70000 (mass ratio of carbon nanotubes to polyethyleneimine 1:1) in deionized water, Then mix, ultrasonic treatment for 1 hour, the power is 250W, make it evenly dispersed, and stir at room temperature for 12 hours, so that polyethyleneimine and acidified carbon nanotubes fully react, the solid product obtained from the reaction is washed with ethanol and water in turn, and suction filtered After separation, polyethyleneimine-grafted carbon nanotubes are obtained.

[0038] (2) Tertiary amination reaction: disperse the carbon nanotube grafted polyethyleneimine prepared in step (1) in deionized water, stir evenly, according to the mass ratio of propylene oxide and polyethyleneimine is 2.5:1 Proportioning, the tertiary amination reagent propylene oxide is slowly added dropwise to the dispersion liquid, stirred and reacted at 3°C for 7 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com