Method for dismounting second-lined reinforced concrete in tunnel

A reinforced concrete and tunnel technology, applied in the direction of tunnel lining, tunnel, earthwork drilling, etc., can solve the problem of shortening, and achieve the effect of reducing disturbance, shortening construction period, and avoiding polluting gas and dust.

Inactive Publication Date: 2015-11-04

GANSU ROAD & BRIDGE CONSTR GROUP +1

View PDF3 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the deficiencies of the prior art, the present invention proposes a method for dismantling the reinforced concrete of the second lining of the tunnel, which effectively solves the disturbance and safety problems caused by blasting and mechanical direct chiseling of the reinforced concrete of the second li

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

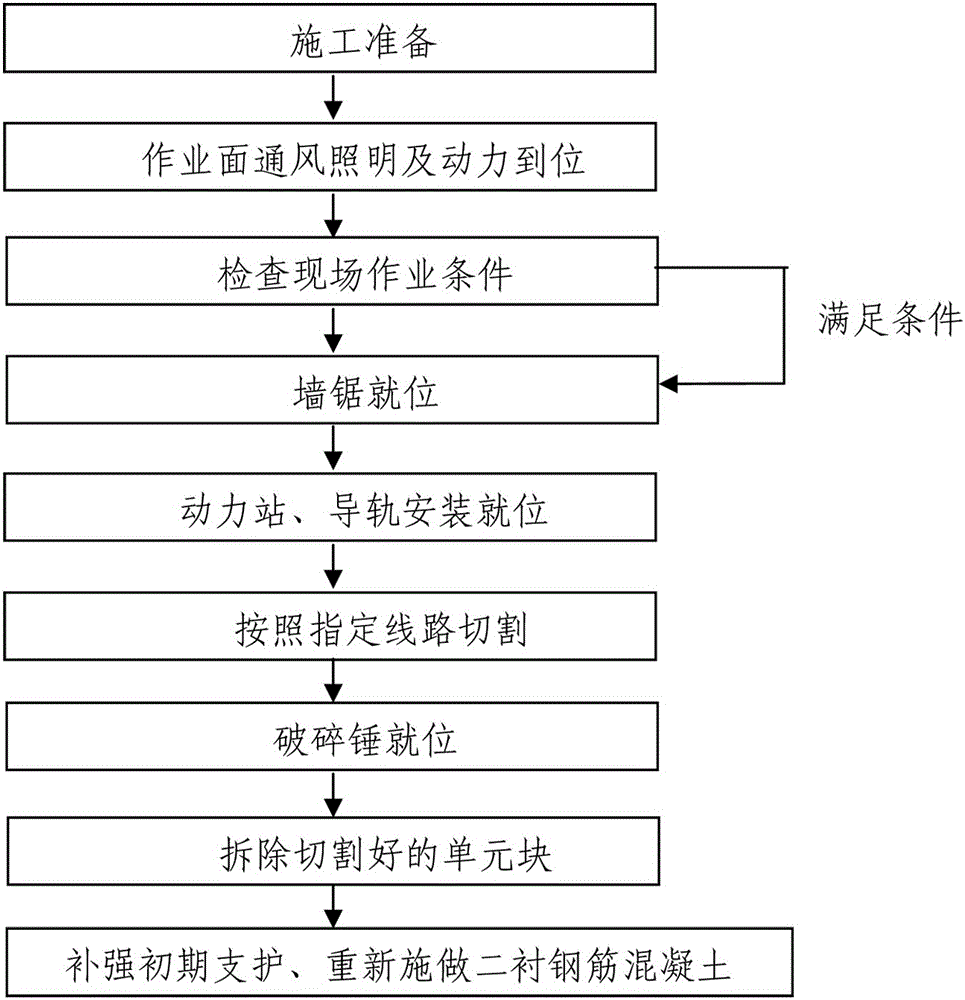

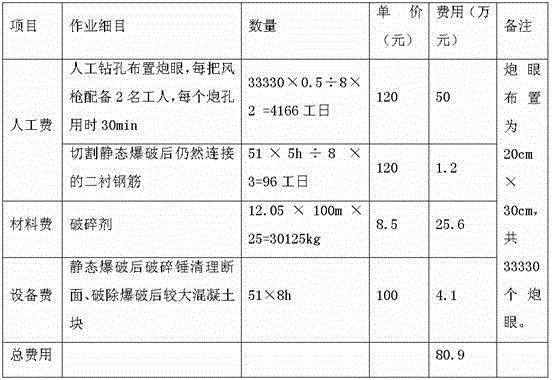

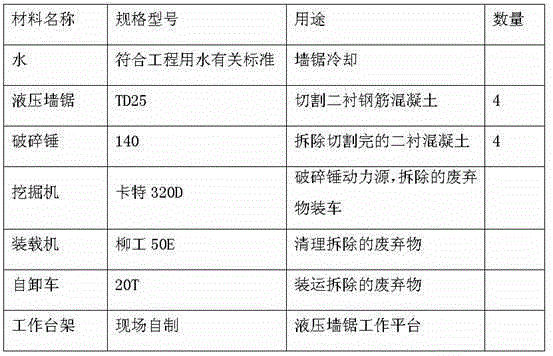

The invention discloses a method for dismounting second-lined reinforced concrete in tunnel, which comprises following steps: (1) reinforcing the to-be-dismounted second-lined reinforced concrete in tunnel; (2) cutting the second-lined reinforced concrete by using hydraulic wall saws; and (3) dismounting the second-lined reinforced concrete by using a breaking hammer. The second-lined reinforced concrete is dismounted by using the hydraulic wall saws cooperating with the breaking hammer. The hydraulic wall saws can be quickly mounted, and have simple operation, low maintenance cost and high cutting efficiency. The original second-lined reinforced concrete is cut into separated unit blocks, and the cut second-lined reinforced concrete is removed by the breaking hammer in a hopping segmented manner, so that the disturbance happened in the surrounding rocks and a supporting construction is effectively reduced, the risk of collapse is avoided, and the safety is quite high; and the construction joints formed by cutting are regular and smooth and has no need to be modified.

Description

technical field [0001] The invention relates to the technical field of tunnel construction, in particular to a method for removing reinforced concrete for the second lining of a tunnel. Background technique [0002] Tunnels located in weak surrounding rocks or areas of high ground stress may suffer from secondary lining cracking, block falling, and cracking due to the passage time of the tunnel, geological conditions of the surrounding rock, survey design, and construction management. In order to ensure the safe operation of the tunnel, it is often necessary to remove the original reinforced concrete secondary lining, and solve the tunnel secondary lining disease by reinforcing the primary support and the secondary lining structure or strengthening the secondary lining structure alone. [0003] The traditional demolition methods of reinforced concrete for secondary lining mainly include controlled blasting, static blasting and direct mechanical chisel removal. Blasting vibr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21F17/00E21D11/10

Inventor 曹贵王海张伟利姜红胡建军

Owner GANSU ROAD & BRIDGE CONSTR GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com