Mounting positioning method of two-way skew curved combined truss

A combined truss and two-way oblique technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as difficulty and achieve fast installation speed, high stability, and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings.

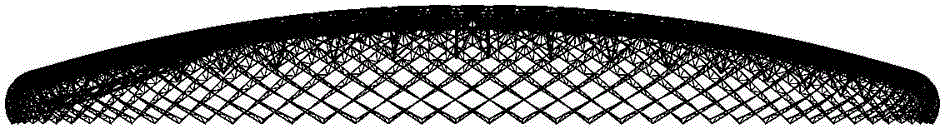

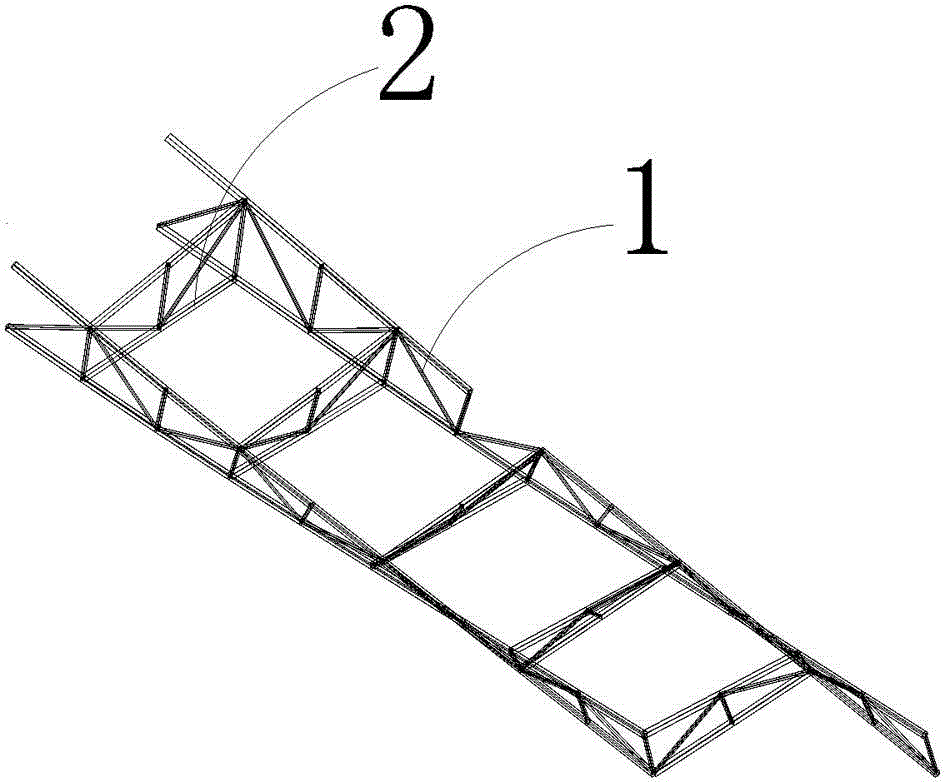

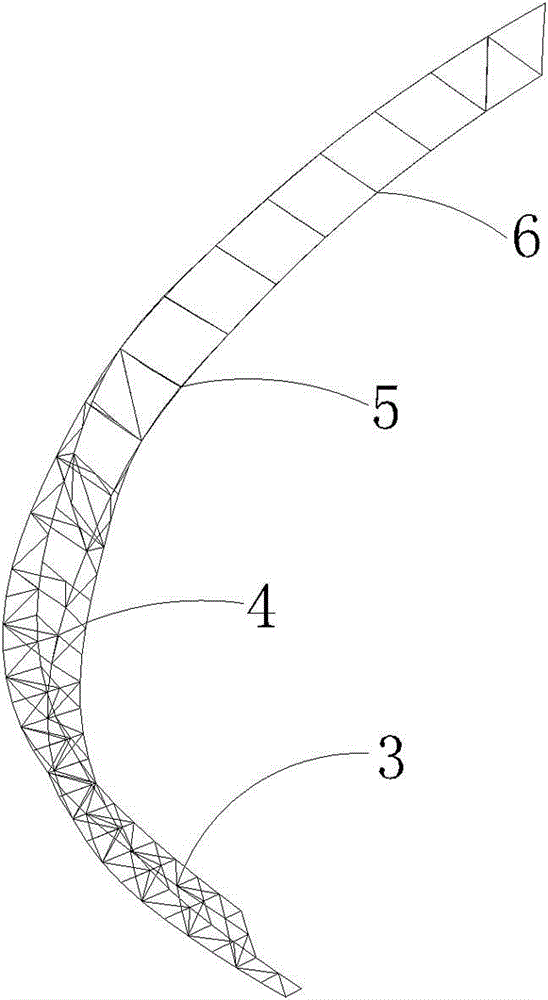

[0036] 1. Example 1: Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a method for installing and positioning a two-way oblique bending composite truss is characterized by the following steps:

[0037] (1) The combined segmentation method of two-way oblique bending composite truss:

[0038] According to on-site construction conditions, one direction is artificially drawn for the main truss, and the two main truss segment units 1 and secondary truss members 2 are combined to form a site hoisting unit;

[0039] Through the connection of each combined lifting unit 3, 4, 5, 6 on the facade, a complete radial combined truss 7 is formed;

[0040] Two adjacent radial composite trusses are connected by secondary truss members 2 to gradually form an overall two-way oblique curved composite truss stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com