LED (light-emitting diode) spliced screen module box

A splicing screen and module technology, which is applied in the direction of cabinet/cabinet/drawer parts, instruments, identification devices, etc., can solve the problems of cumbersome splicing screen construction process, time-consuming and labor-consuming, low operation efficiency, etc., to achieve Save labor costs and time costs, improve implementation efficiency, and speed up installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

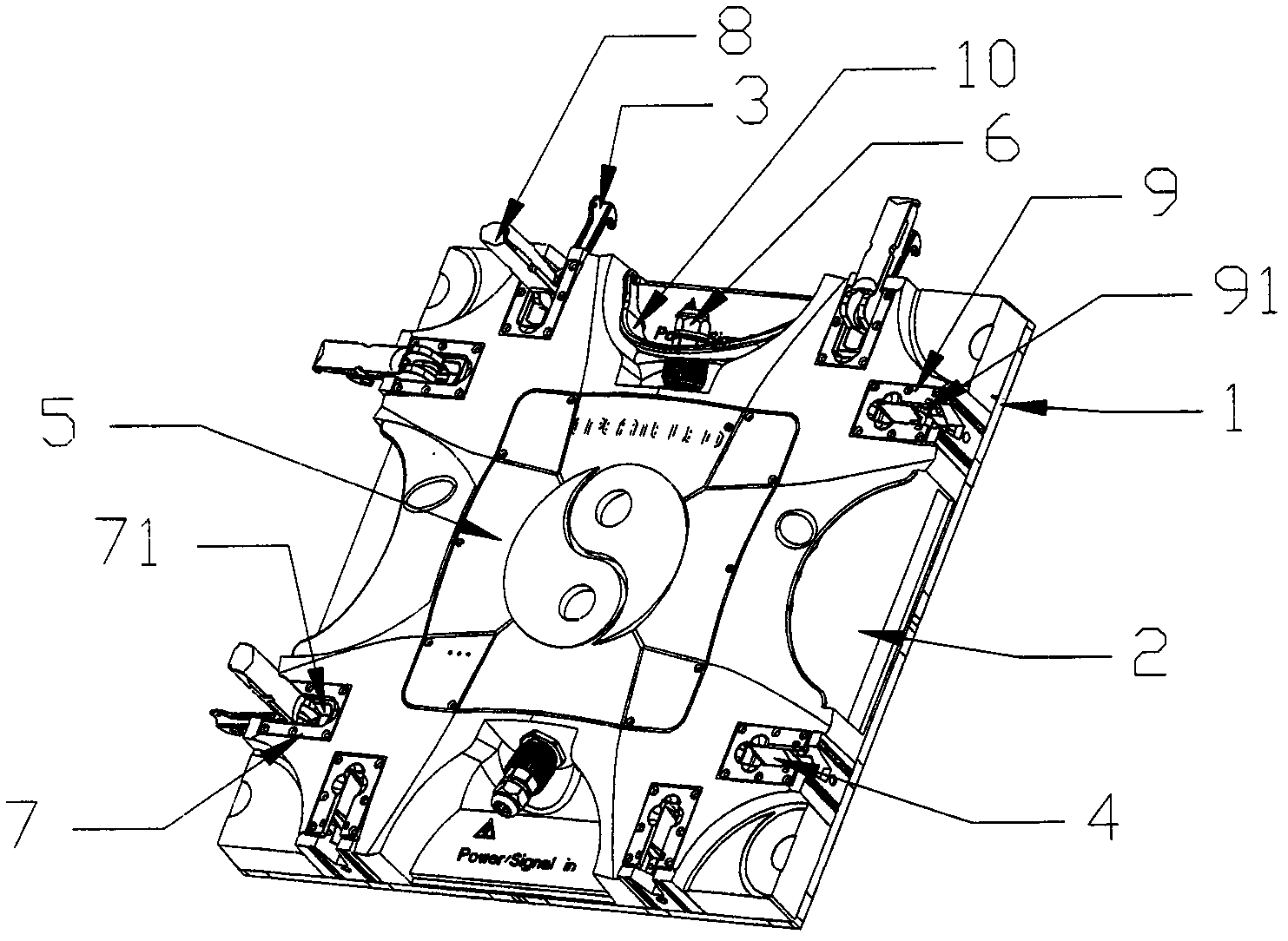

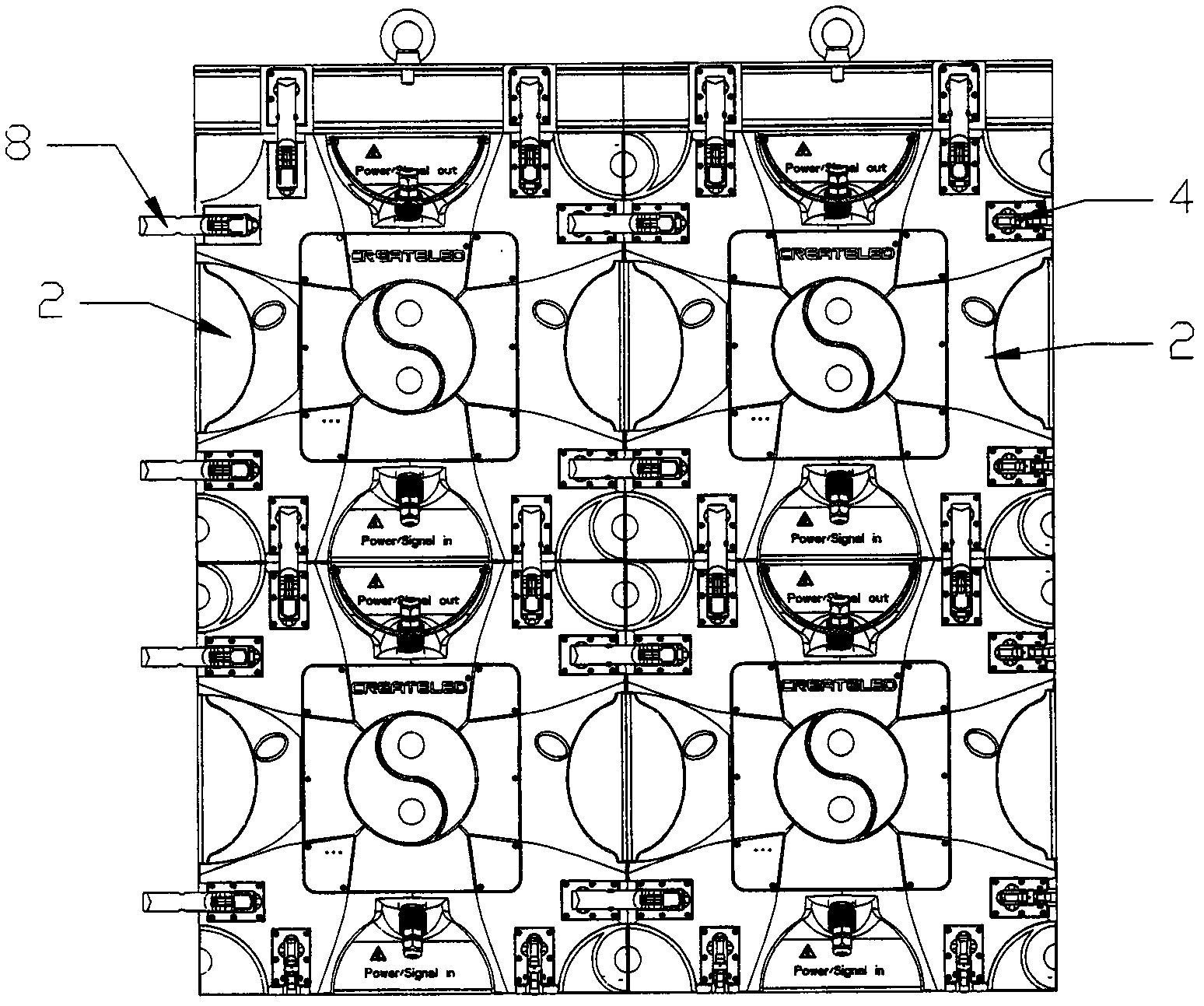

[0015] Such as figure 1 and figure 2 As shown, the LED splicing screen module box in this embodiment includes a rectangular or square panel 1 and a main box 2, the main box 2 is arranged behind the panel 1, and each side of the main box 2 There are lock hooks 3 and / or lock grooves 4 for the lock hooks 3 to fasten, and the lock hooks 3 and lock grooves 4 on the opposite two sides are arranged oppositely. The locking hooks 3 and the locking grooves 4 have the same number and the same positions.

[0016] In this embodiment, for the convenience of installation, multiple locking hooks 3 are provided on two adjacent sides of the main box body 2 , and locking grooves corresponding to the positions of the locking hooks are provided on the other two adjacent sides.

[0017] Specifically, the middle part of the main box body 2 is provided with a cavity for installing a power supply, a rear cover 5 is provided on the cavity, and a connector 6 is provided beside the cavity.

[0018] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com