Mounting structure of concave keel wall space wood veneer

A technology for installing structure and wood veneer, which is applied in building construction, covering/lining, construction, etc., can solve the problems of energy waste, wood veneer can not be reused, and installation loss is large, so as to achieve low installation loss and installation. Fast, firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

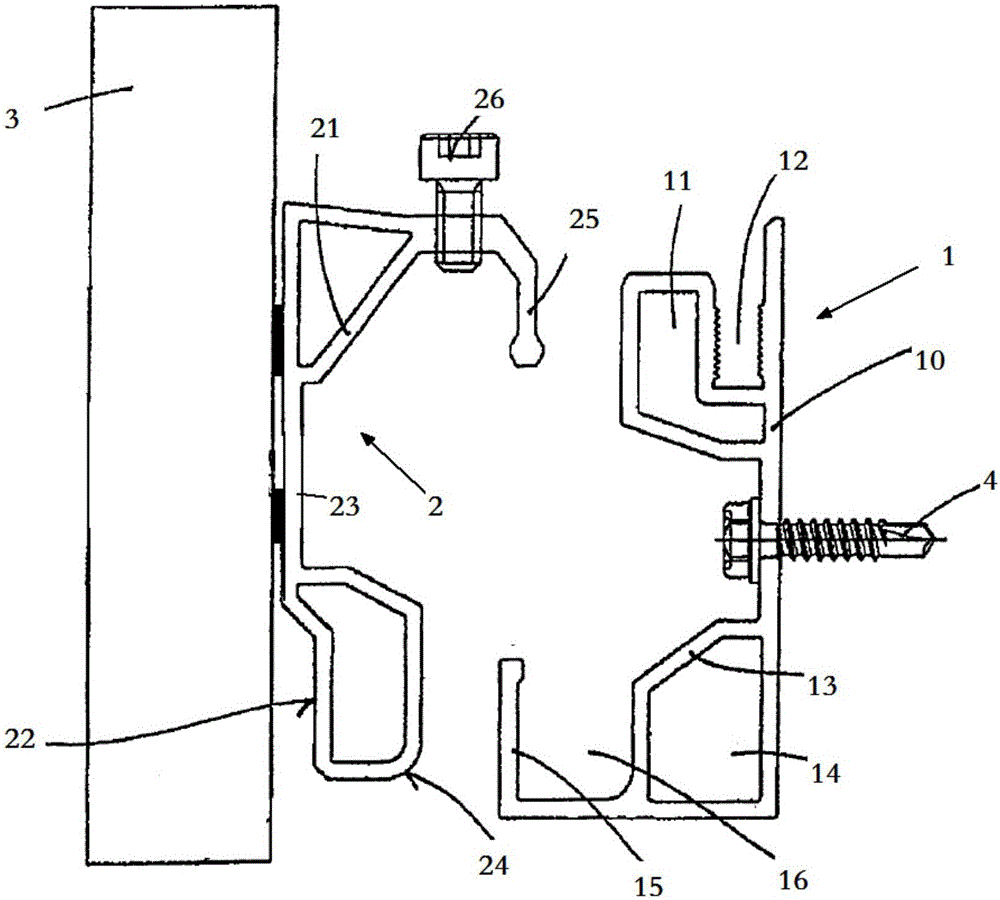

[0020] like figure 1 As shown, a kind of installation structure of wood trim on the wall surface of concave keel, including wood trim 3 and concave keel, the concave keel is composed of two parts, male keel 2 and female keel 1, and female keel 1 is connected by self-tapping screws 4 Fixed on the wall beam or purlin (not shown in the figure), the male keel 2 is bonded on the back side of the wood veneer 3 by structural glue, and the male keel 2 includes the middle board 23, the upper connection part arranged on the middle board 23 top 21 and the lower connection part 22 that is arranged on the middle plate 23 bottoms, the upper connection part 21 is made of a triangular frame, and the front end of the upper connection part 21 protrudes outwards with an L-shaped plug-in part 25, and the front end of the plug-in part 25 Vertically downward, a tightening bolt 26 is vertically arranged on the horizontal part of the insertion part 25 . The lower connecting portion 22 is a polygonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com