Moving-out type ultra-fan engine

An engine and removal technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problem that the fan and the low-pressure turbine cannot reach the optimal speed at the same time, the ADP is difficult to put into practical use, the installation loss increases, etc., to achieve safety. Improved performance, reduced moment of inertia, and reduced exhaust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

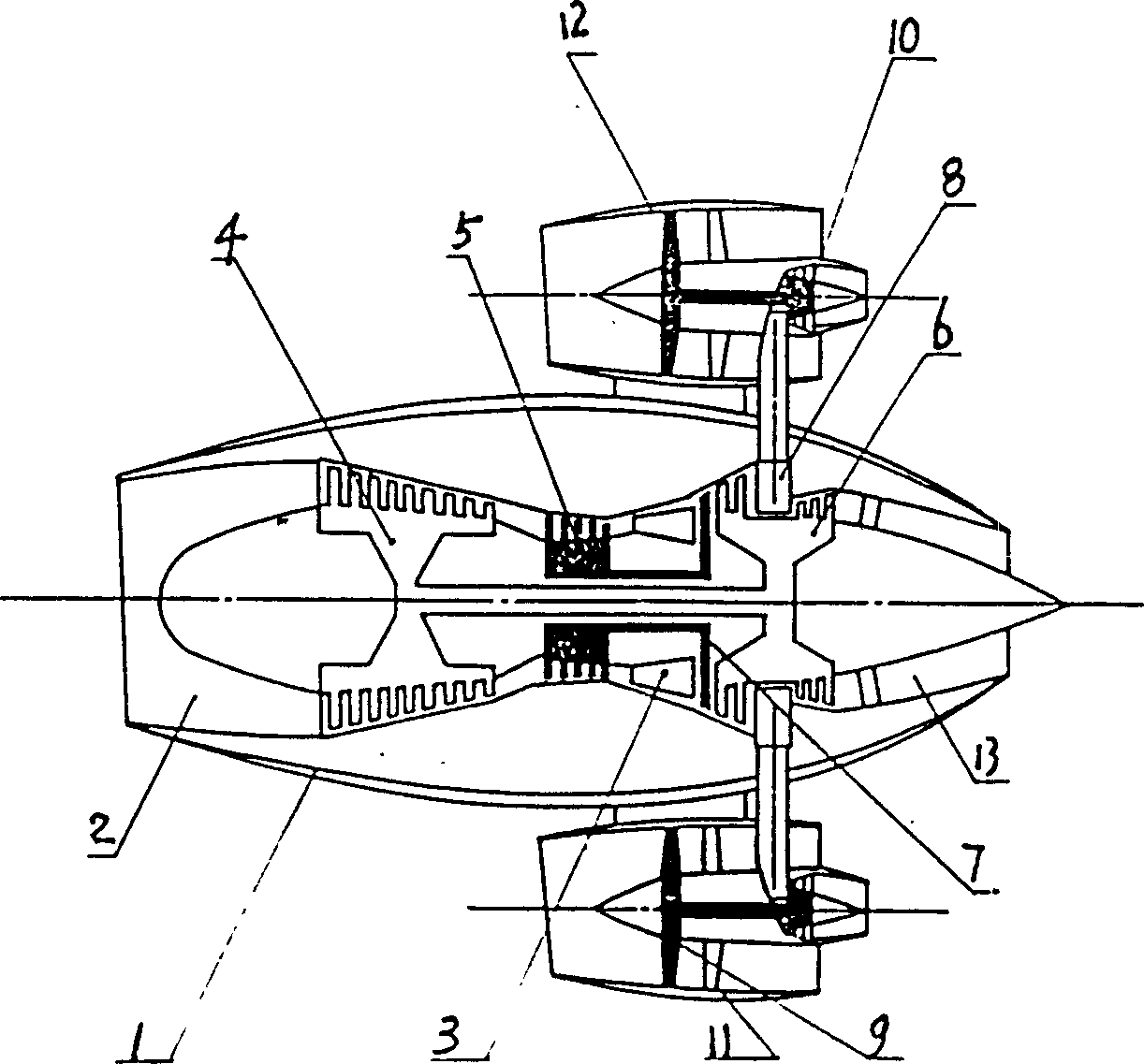

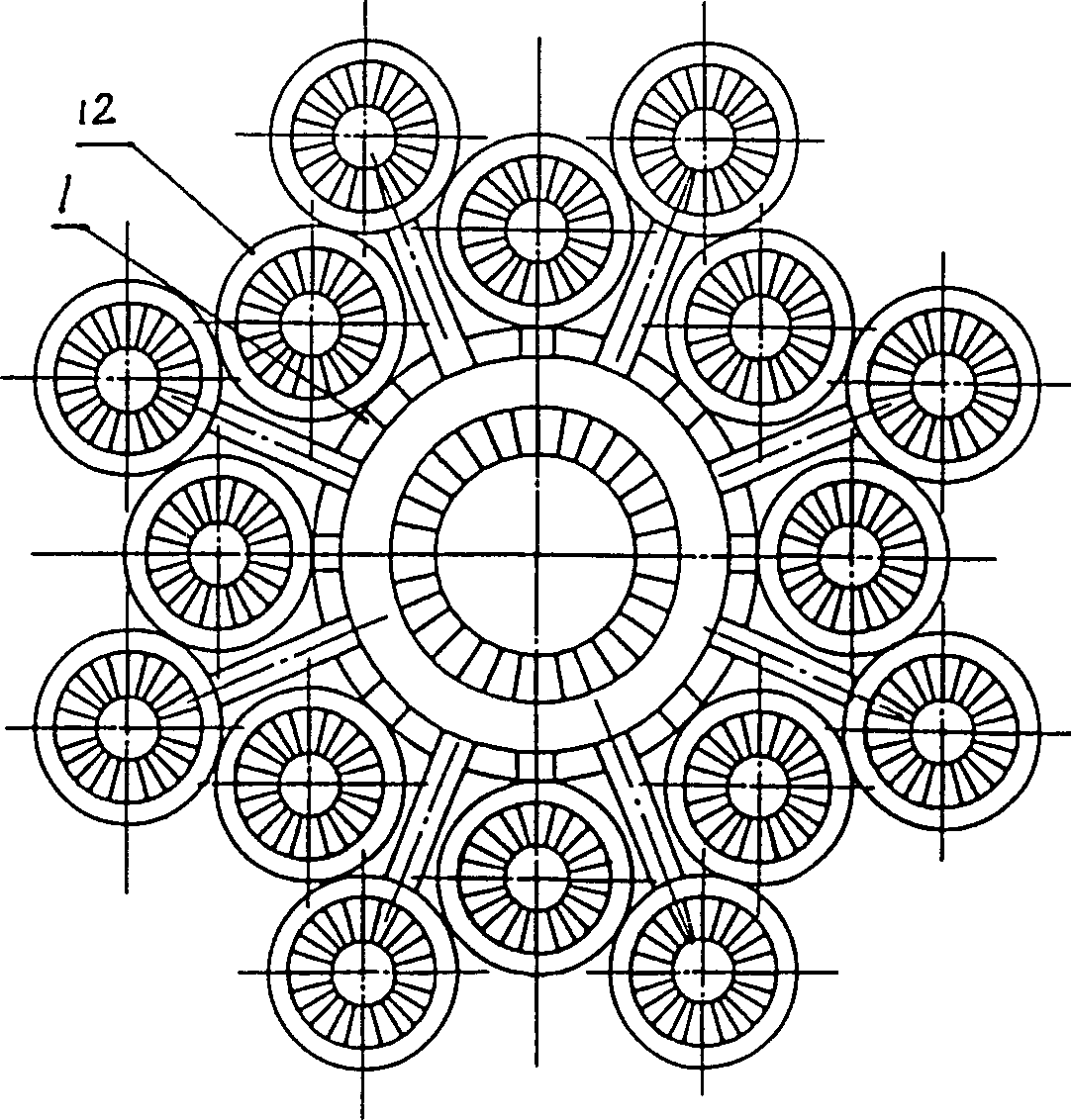

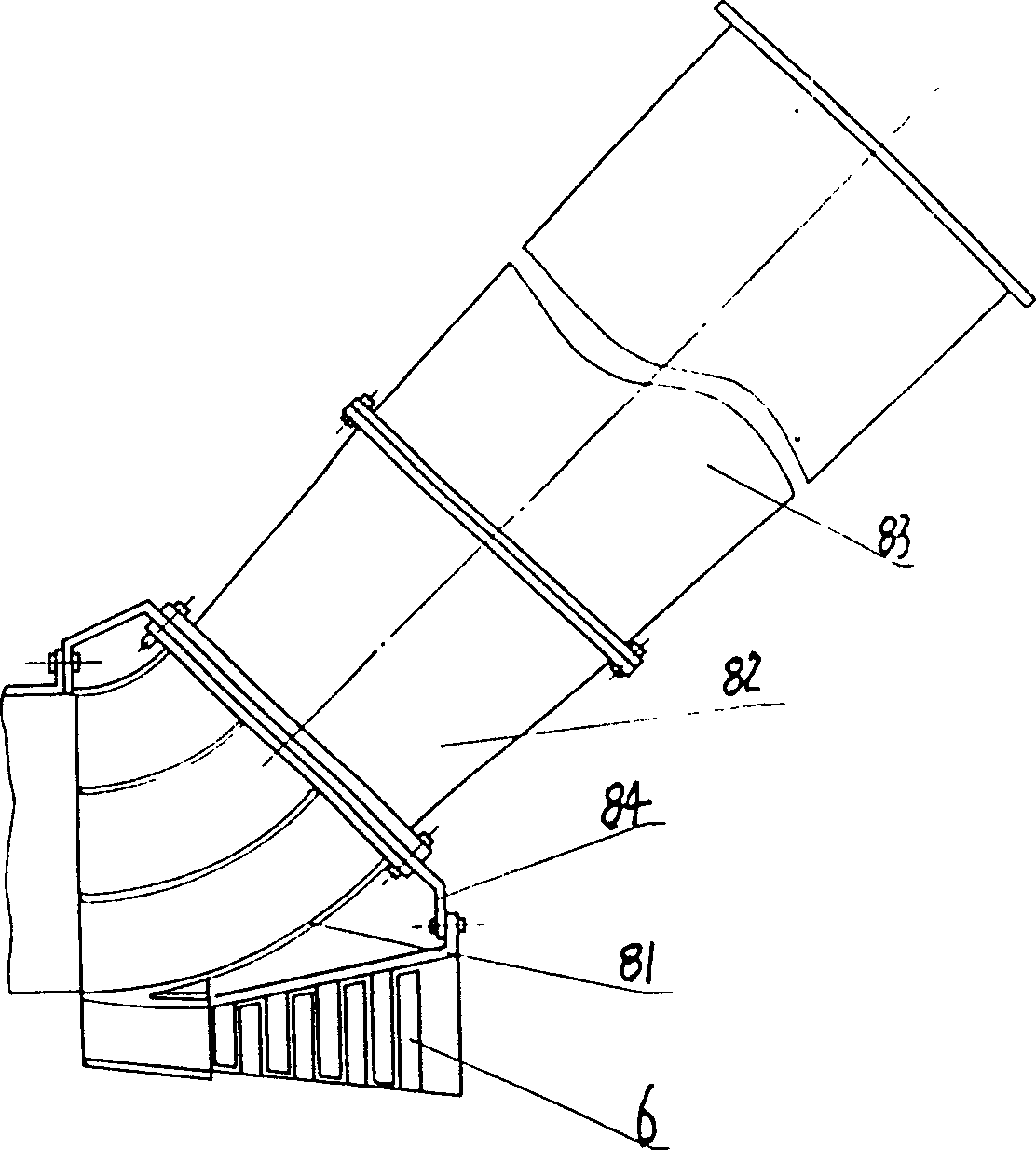

[0027] see figure 1 , figure 2 , the present invention is made up of main engine 1 including air inlet 2, combustion chamber 3, high-pressure compressor 5, low-pressure compressor 4, high-pressure turbine 7, low-pressure turbine 6, tail nozzle 13 and auxiliary turbofan 12. After the first or second stage of the low-pressure turbine 6, a gas splitting device 8 is provided, figure 1 In the middle, a gas distribution device is provided between the second and third stages, and a total of 16 auxiliary turbines 10 connected with the gas distribution device 8 are arranged around the main engine 1, and each auxiliary turbine 10 is used to drive a small fan 9, forming The auxiliary turbofan 12 is located in the nacelle 11 and bound around the main engine 1 . The structure of the gas splitting device 8 of the present invention is as image 3 As shown, it is composed of a flow divider 81, a flow confluence 82 and a flow divider (i.e., a diffuser) 83. The flow divider 81 is a thin-wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com