Inflatable blade structure of wind driven generator

A technology of wind turbine and blade structure, which is applied to wind turbines, wind turbines consistent with the wind direction, and wind power generation. It can solve problems such as difficulty in project site completion, overall size cannot be reduced, and length and size exceed the standard. Reduce the risk of blade breakage and tower collapse, reduce transportation volume and transportation costs, and reduce the effect of cut-in wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific examples.

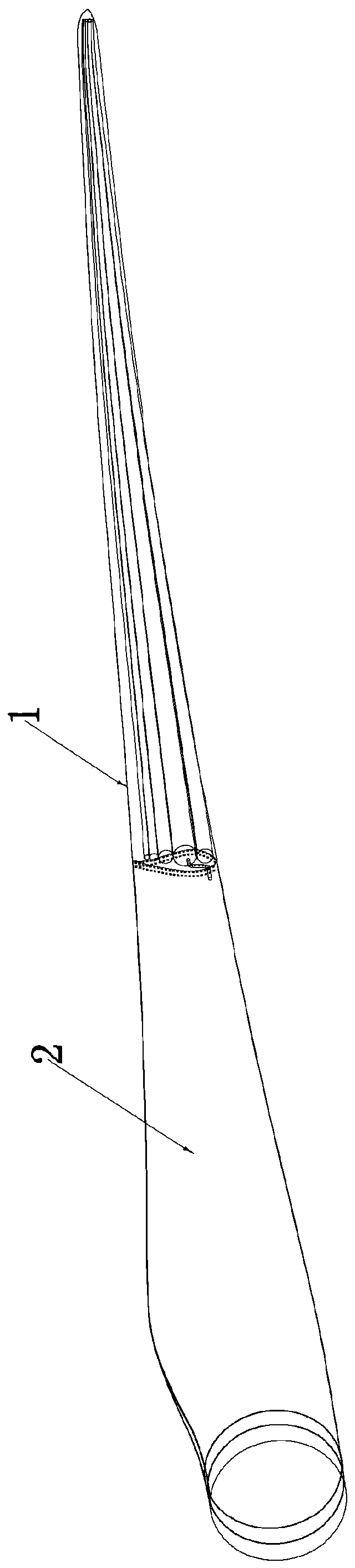

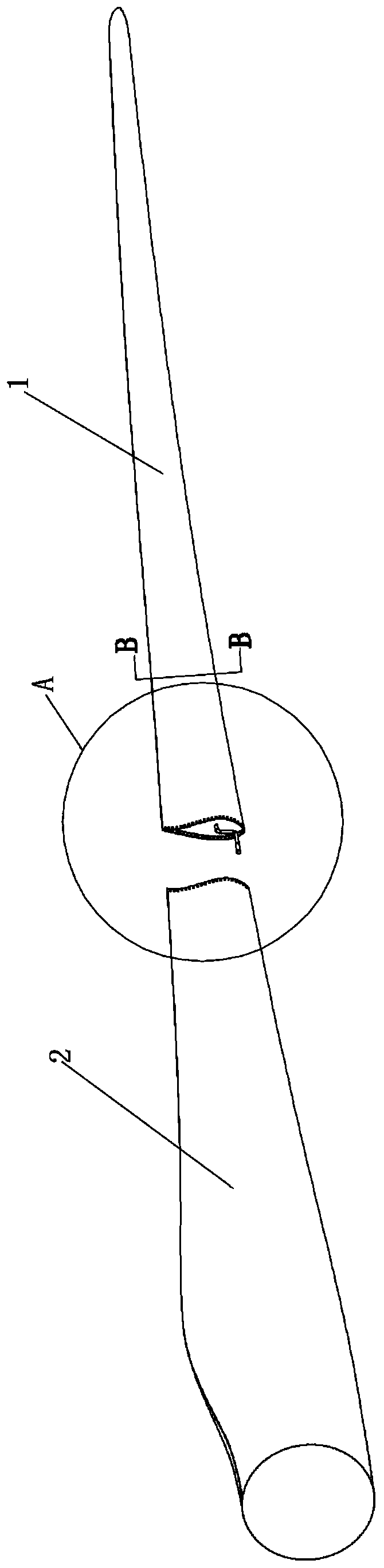

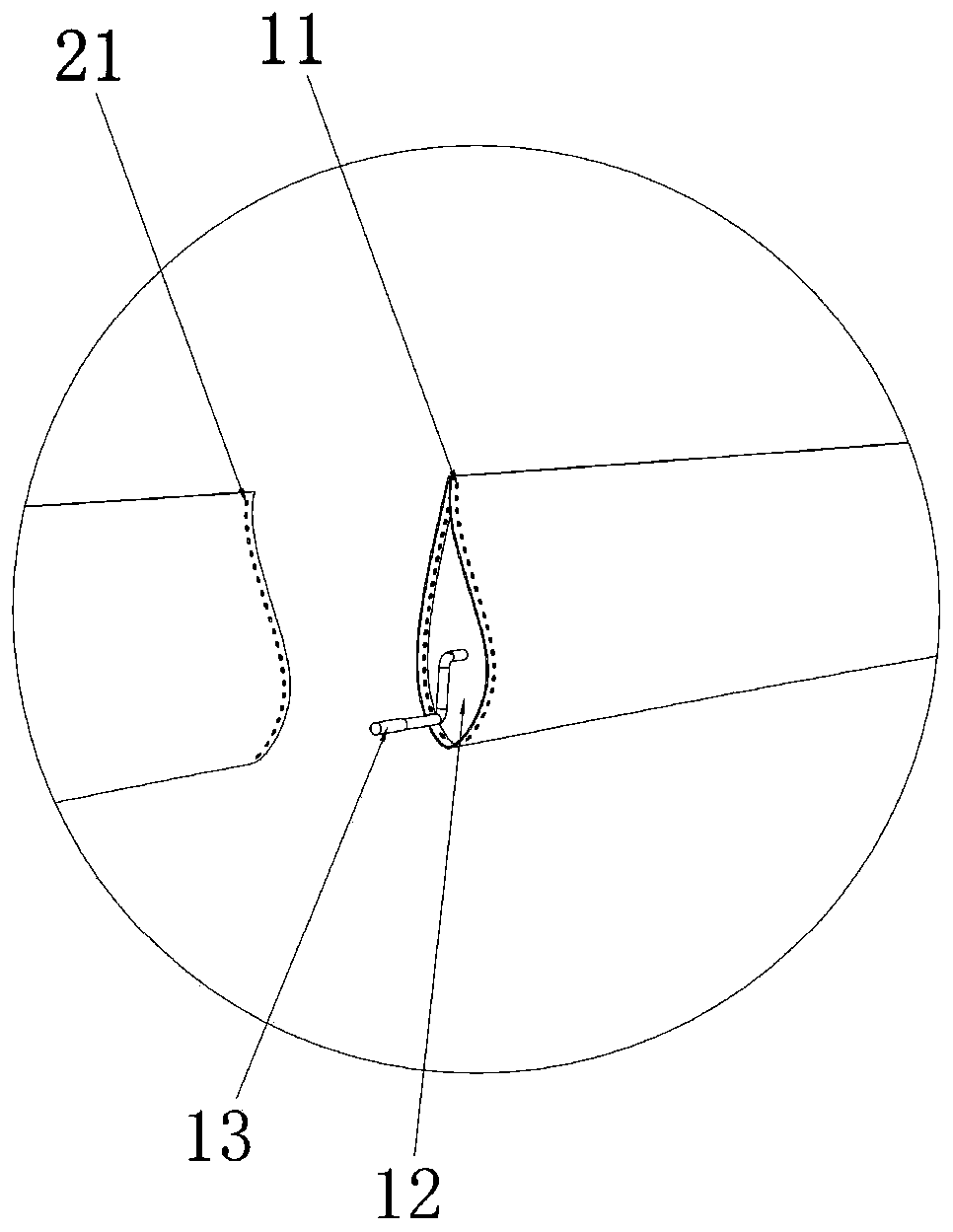

[0021] Such as Figure 1 to Figure 5 As shown, the wind turbine inflatable blade structure described in this embodiment includes a glass fiber blade root section 2 and an inflatable blade tip section 1, and the inflatable blade tip section 1 is bonded to the glass fiber blade root section 2 by applying glue. Finally, and fixed by rivets, wherein, the end edge of the fiberglass blade root section 2 connected with the inflatable tip section 1 is pre-embedded with a plurality of buckles 21, and each buckle 21 is equipped with a connecting rivet. It is used to connect with the inflatable blade tip section 1, and the end edge of the inflatable blade tip section 1 connected with the fiberglass blade root section 2 is installed with a plurality of grommets 11, and a mounting plate is glued on the inside of the end 12. The number of the buttonholes 11 is consistent with that of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com