Construction method for assembly type light-steel integrated house in pasturing area

A technology that integrates housing and construction methods. It is applied in the direction of building structure, construction, and building material processing. It can solve problems such as waste of resources, destruction of cultivated land, and ecological damage to grasslands. Good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

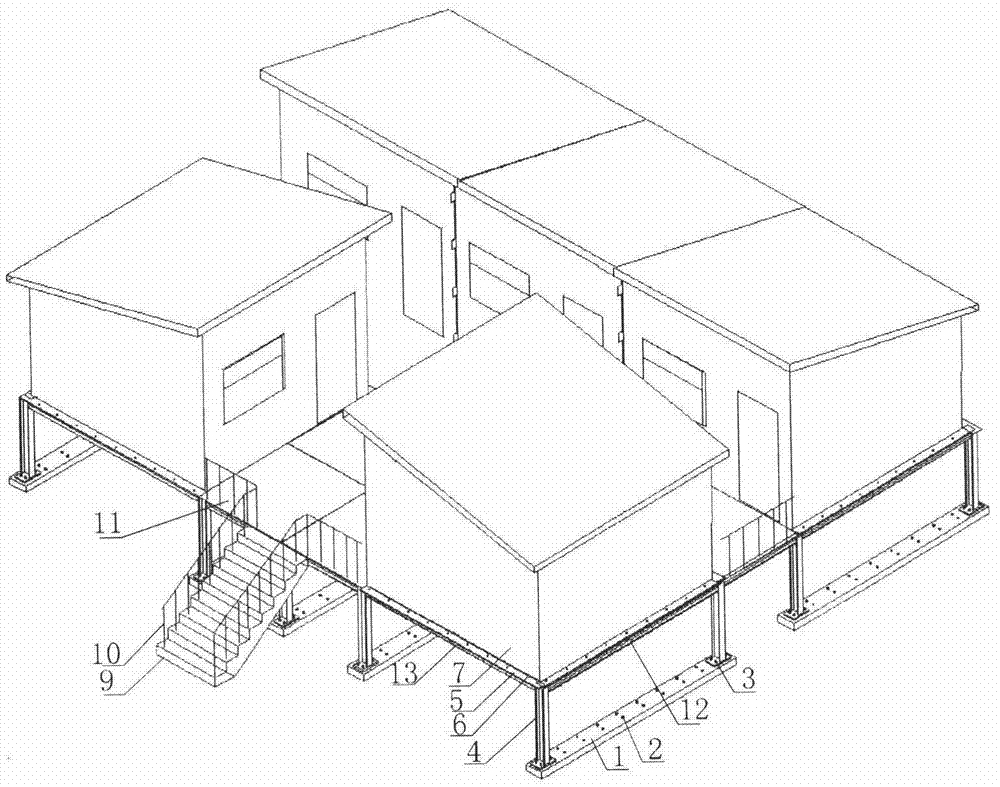

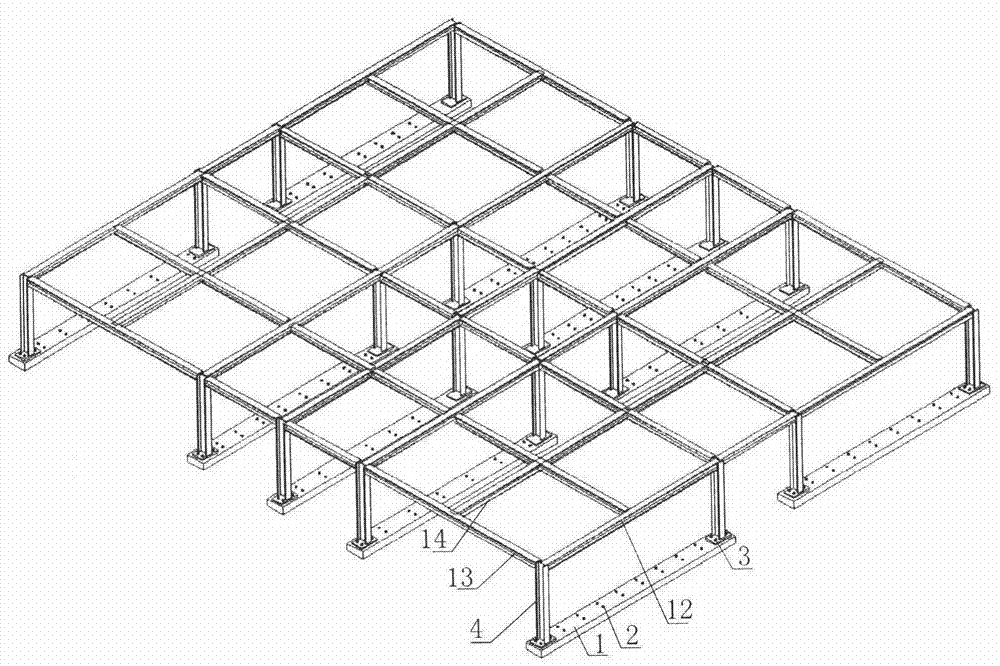

[0040] Such as Figure 1-Figure 8 , a method for constructing a prefabricated light steel integrated house in a pastoral area, characterized in that:

[0041] A. Prepare enough: prefabricated reinforced concrete ground beam 1, foundation long anchor rod 2, first floor frame column 4, bolts 6, nuts, cold-formed thin-walled steel integrated single house 7, roof 11, first floor frame beam 12, 1st floor frame stringer 13, composite staircase 9;

[0042] in:

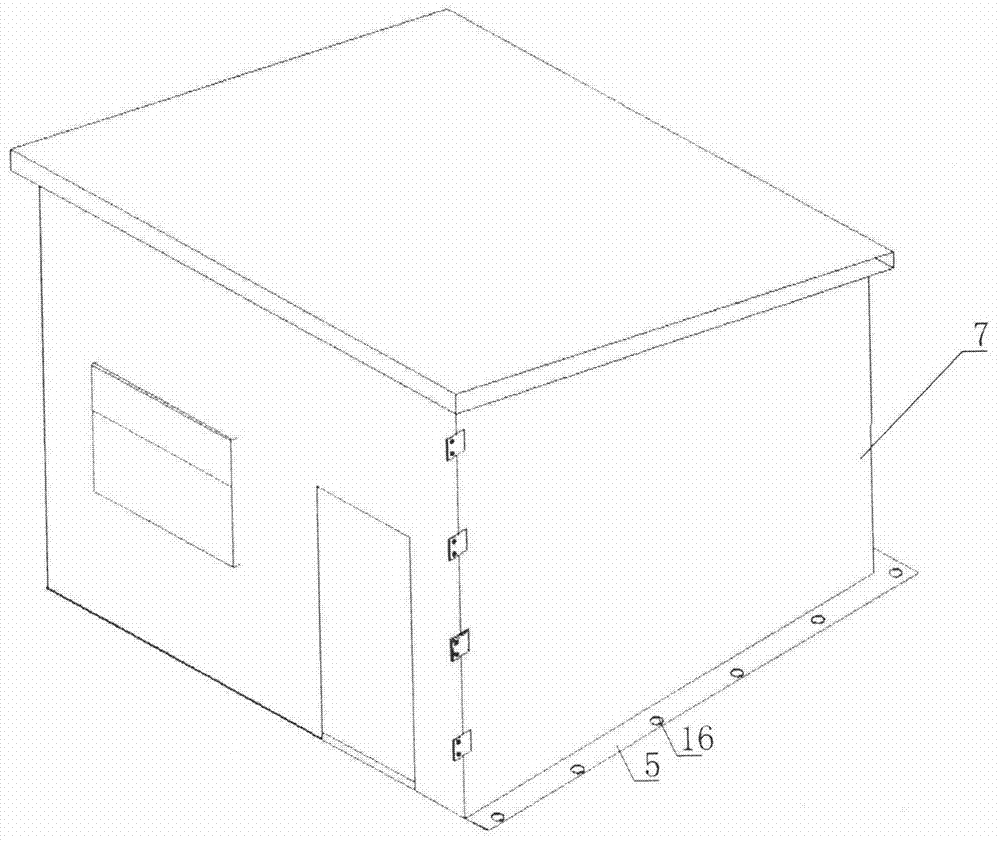

[0043] A connecting plate 5 is provided at the bottom of the cold-formed thin-walled steel integrated single house 7, and a hole 16 is opened on the connecting plate 5;

[0044] Both ends of the prefabricated reinforced concrete ground beam 1 are provided with embedded bolts 3, and a vertical hole 16 is reserved in the prefabricated reinforced concrete ground beam 1;

[0045] End plates 15 are provided at both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com