Prefabricated house wallboards, fully prefabricated house using wallboards, and installation method for fully prefabricated house

An installation method and wall panel technology, which are applied in the processing of walls, building materials, and building components, can solve the problems of affecting the strength of connecting steel bars, high welding labor intensity, and slow installation speed, so as to save manpower, fast installation speed, Good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

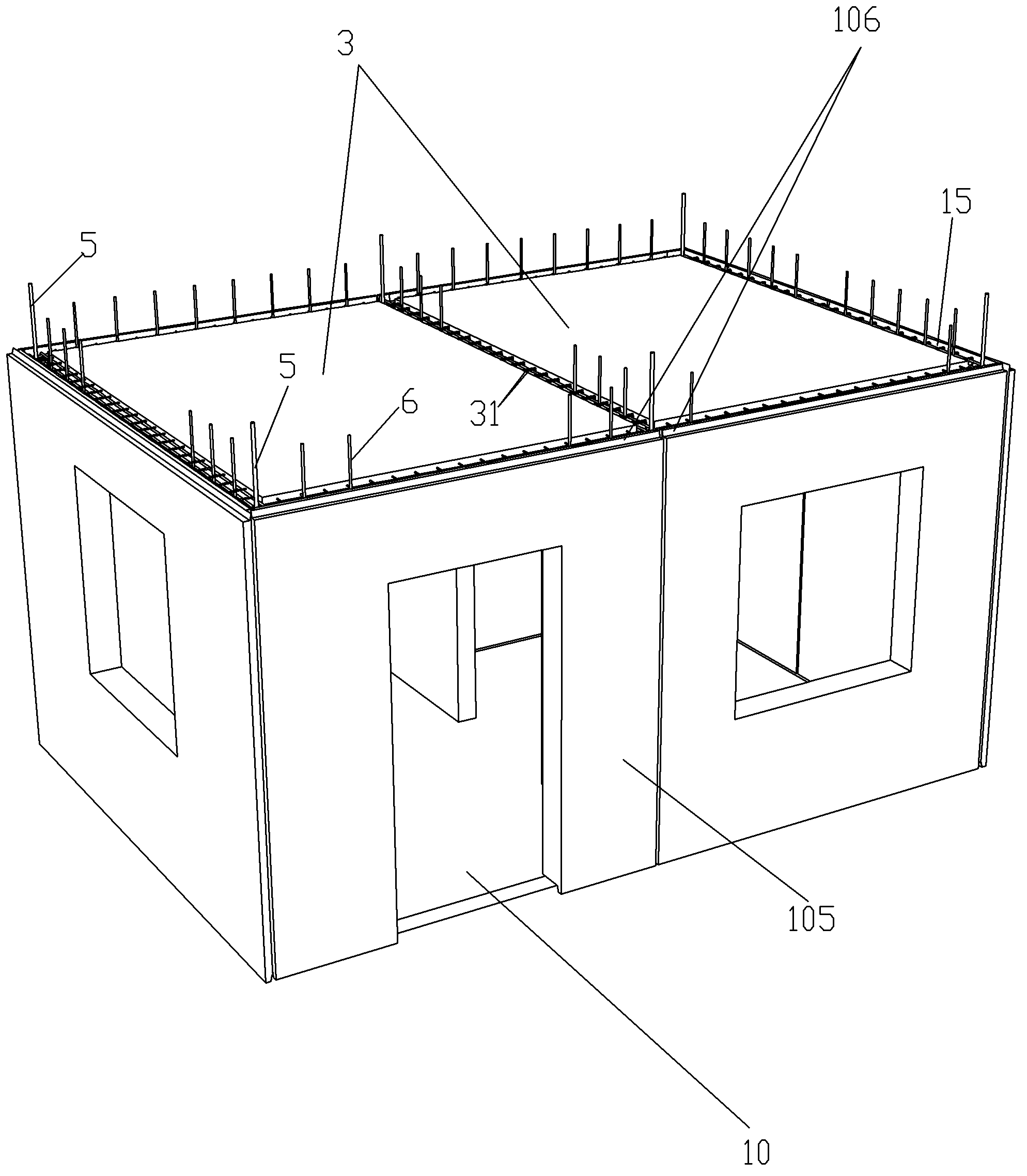

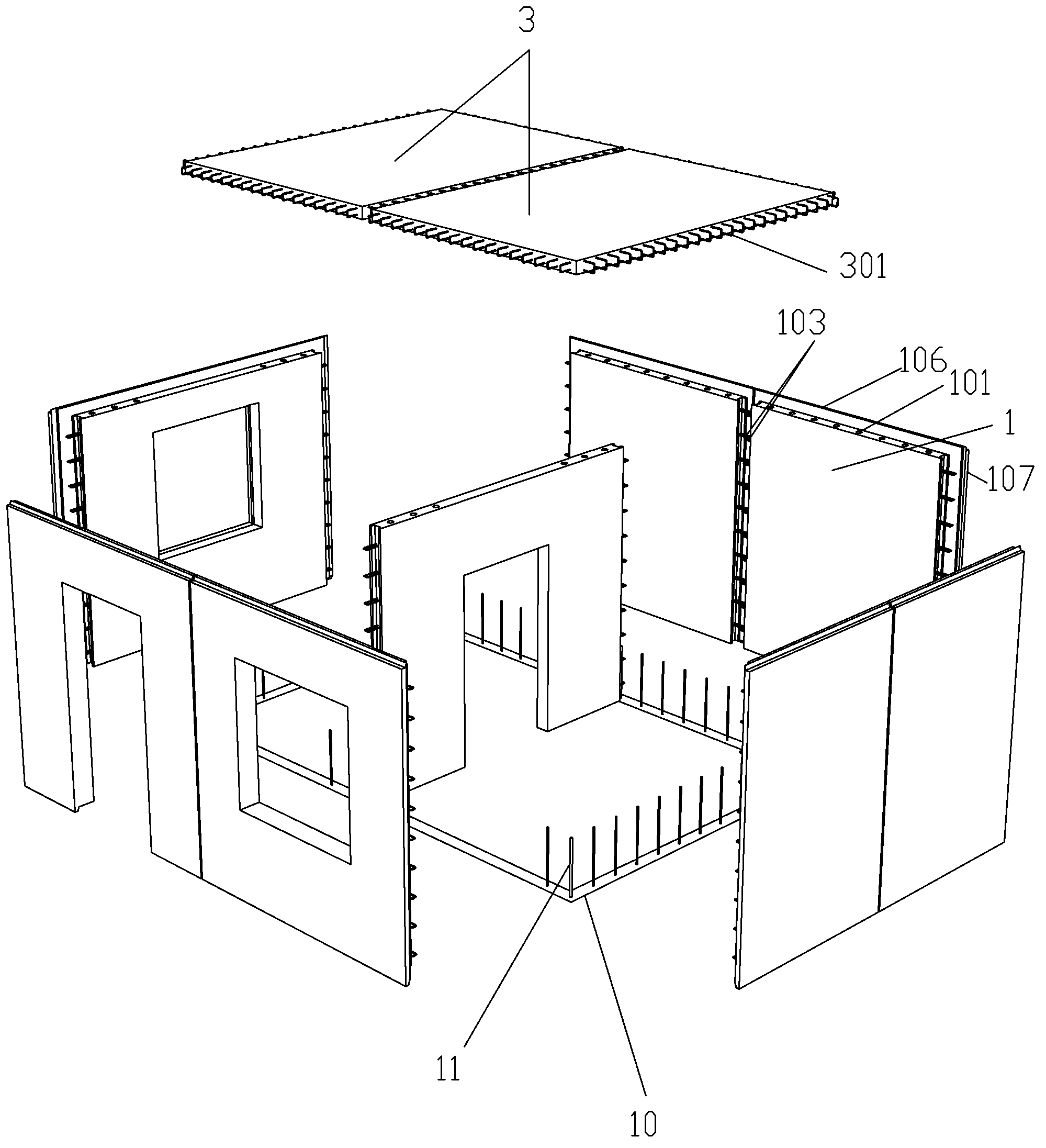

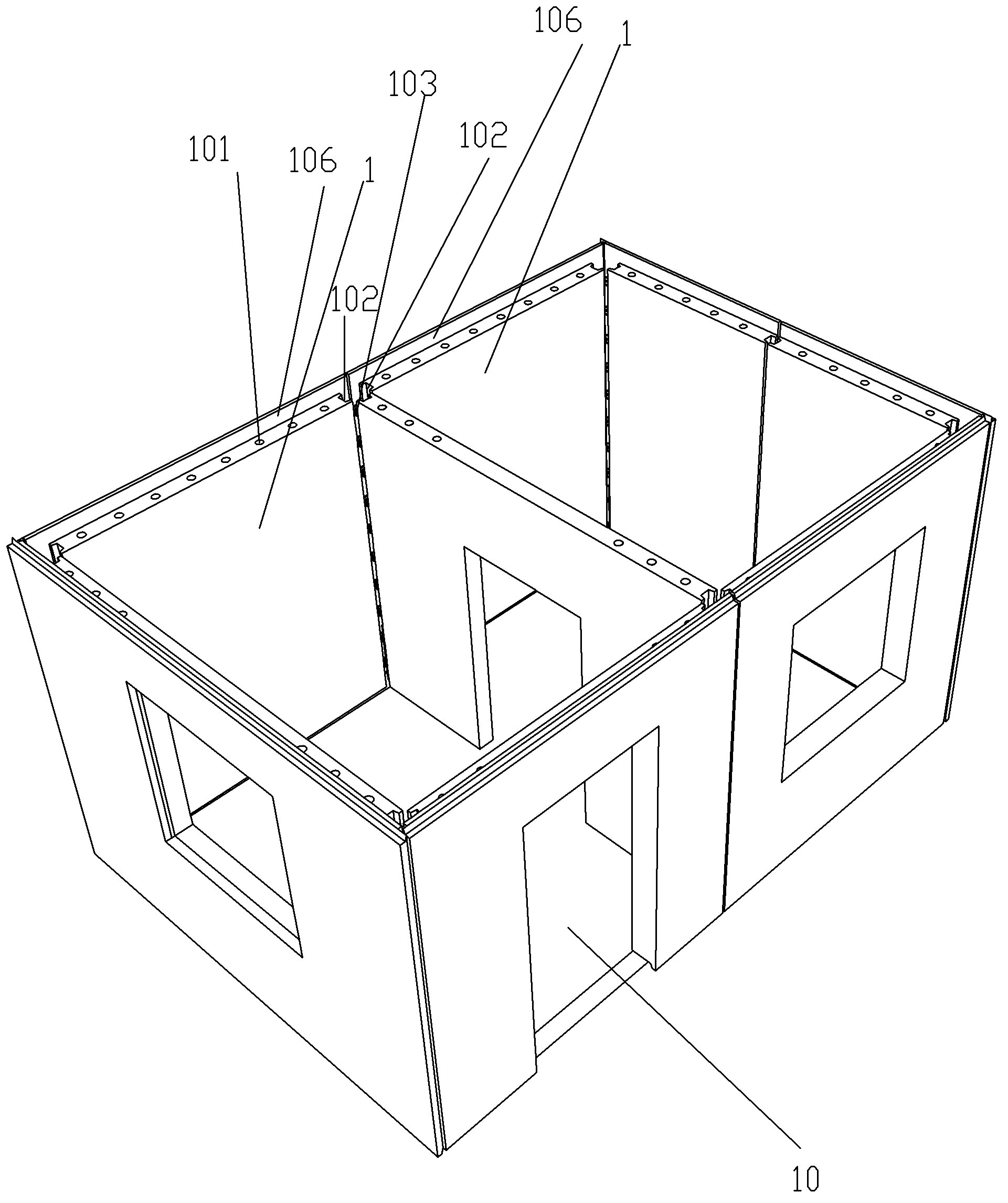

[0036] A prefabricated house wall panel, comprising a wall panel body 1, the wall panel body 1 is provided with a vertical hole 101 passing through its upper and lower ends for interspersing secondary connecting steel bars, and the two sides of the wall panel body 1 are provided with There is a vertical groove 102, and a plurality of reserved sleeves 103 for connection between wall panels are arranged in the vertical groove 102.

[0037] The reserved cover 103 is a steel bar cover or a wire rope cover.

[0038] A fully prefabricated house, comprising a base 10, the base 10 is surrounded by a plurality of wall panels 1, the base 10 is provided with connecting steel bars 11, and the wall panels 1 are provided with Through the vertical holes 101 at its upper and lower ends, the two sides of the wallboard body 1 are provided with vertical grooves 102, and the vertical grooves 102 are provided with a plurality of reserved sleeves 103 for connection between wallboards , the reserve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com