Building method of integral slip type scaffold used for steel grid construction

A scaffolding and steel grid technology, applied in the direction of construction, building structure, housing structure support, etc., can solve the problems of complicated construction, insufficient stability, complex sliding scaffolding structure, etc. Effect of rack installation safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

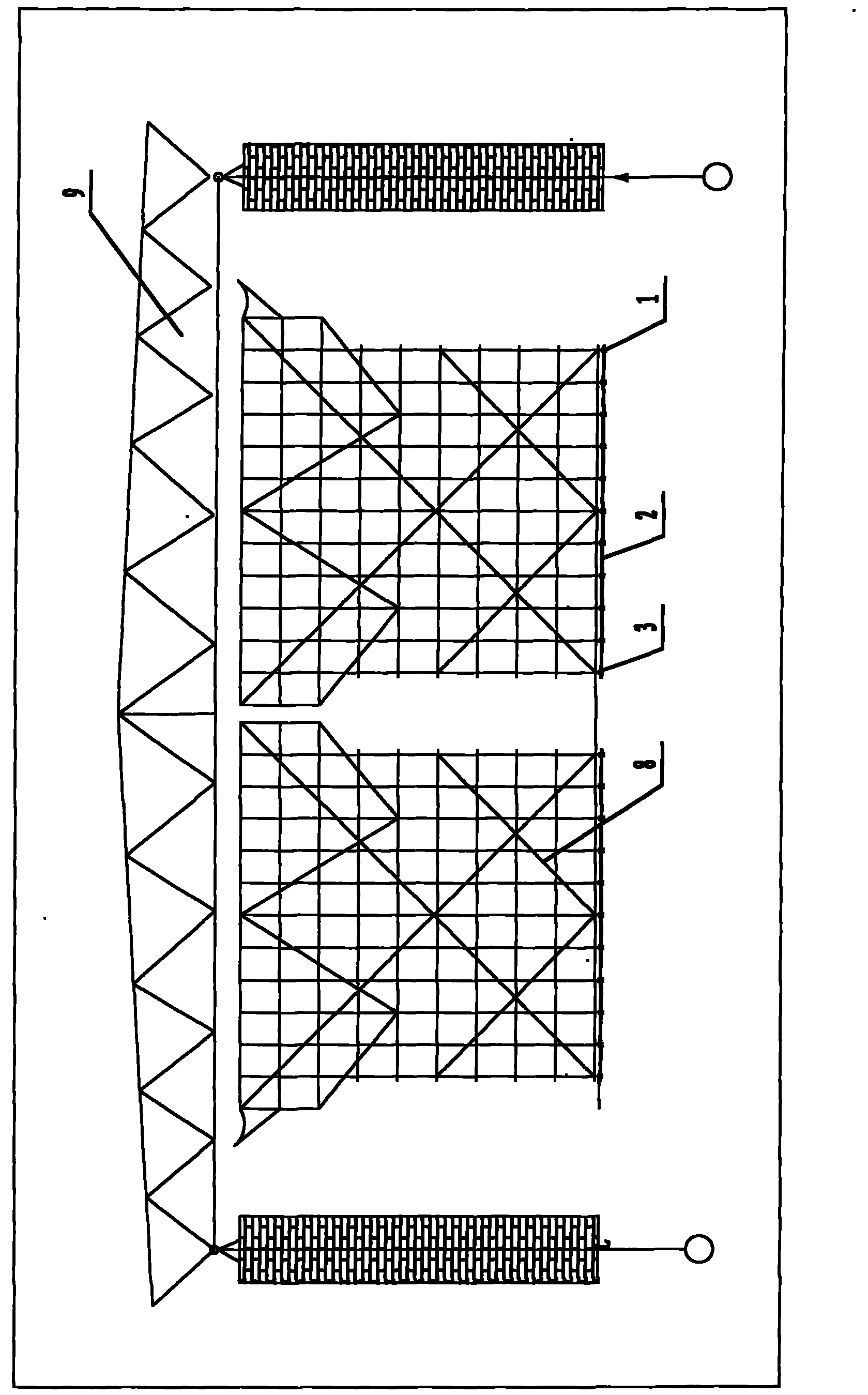

[0032] Project example 1: Painting workshop project of civil ship project of CSSC Longxue Shipbuilding Base (construction date: July 2007-September 2008)

[0033] This project includes two single units, the sandblasting workshop and the painting workshop, with a total construction area of 44968m2 2 . Build two single-story multi-span steel structure workshops (sandblasting workshop and painting workshop) and a painting storage yard within the scope of the land, and the sandblasting workshop covers an area of 16765m 2 , construction area 24258m 2 , the workshop span is 30m×6, and the partial height of the building is 21.15m; the painting workshop covers an area of 15984m 2 , construction area is 20710m 2 , the workshop span is 30m×7, the partial height of the building is 21.15m; the coating yard area is 28000m 2 , asphalt concrete floor.

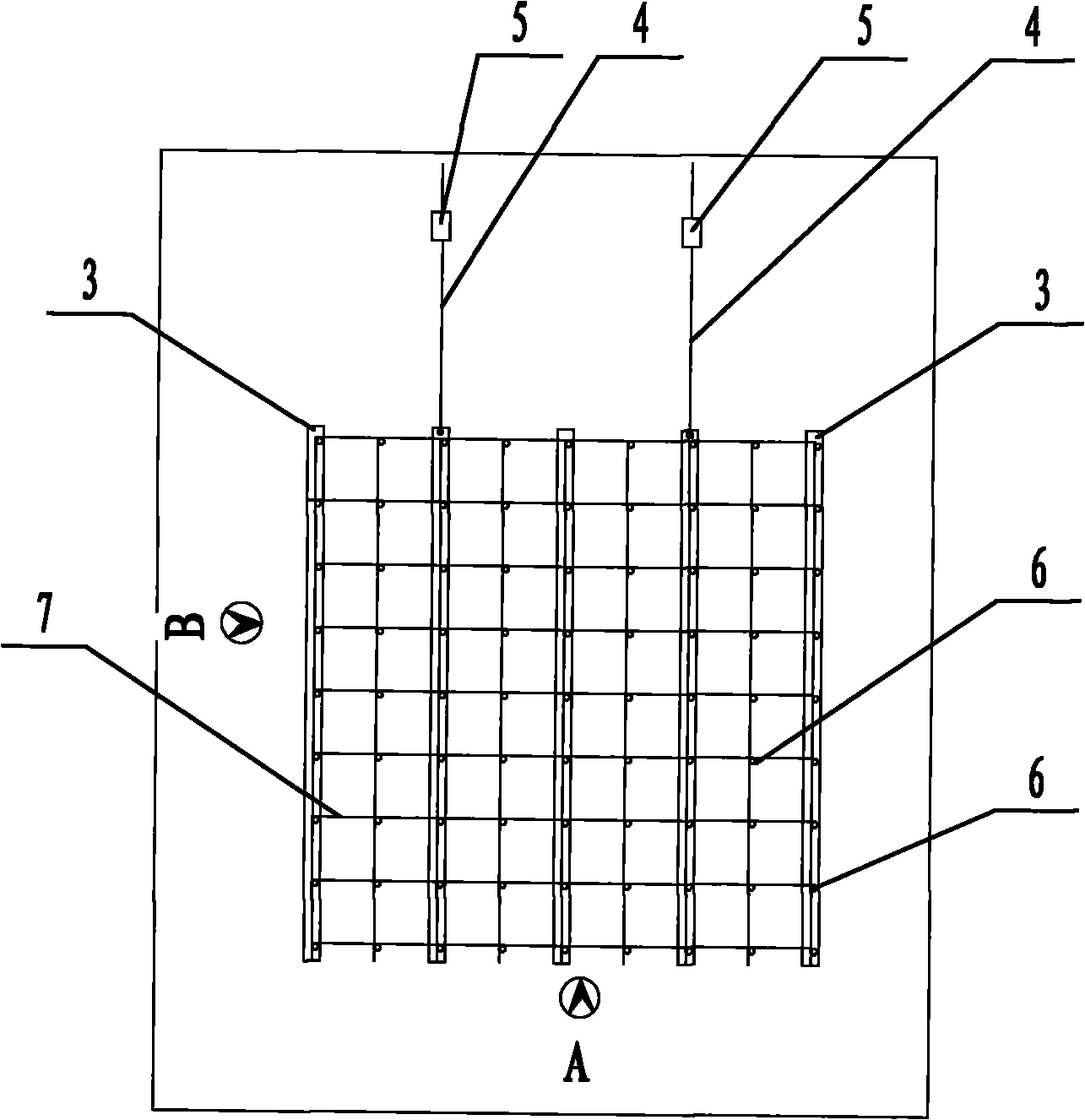

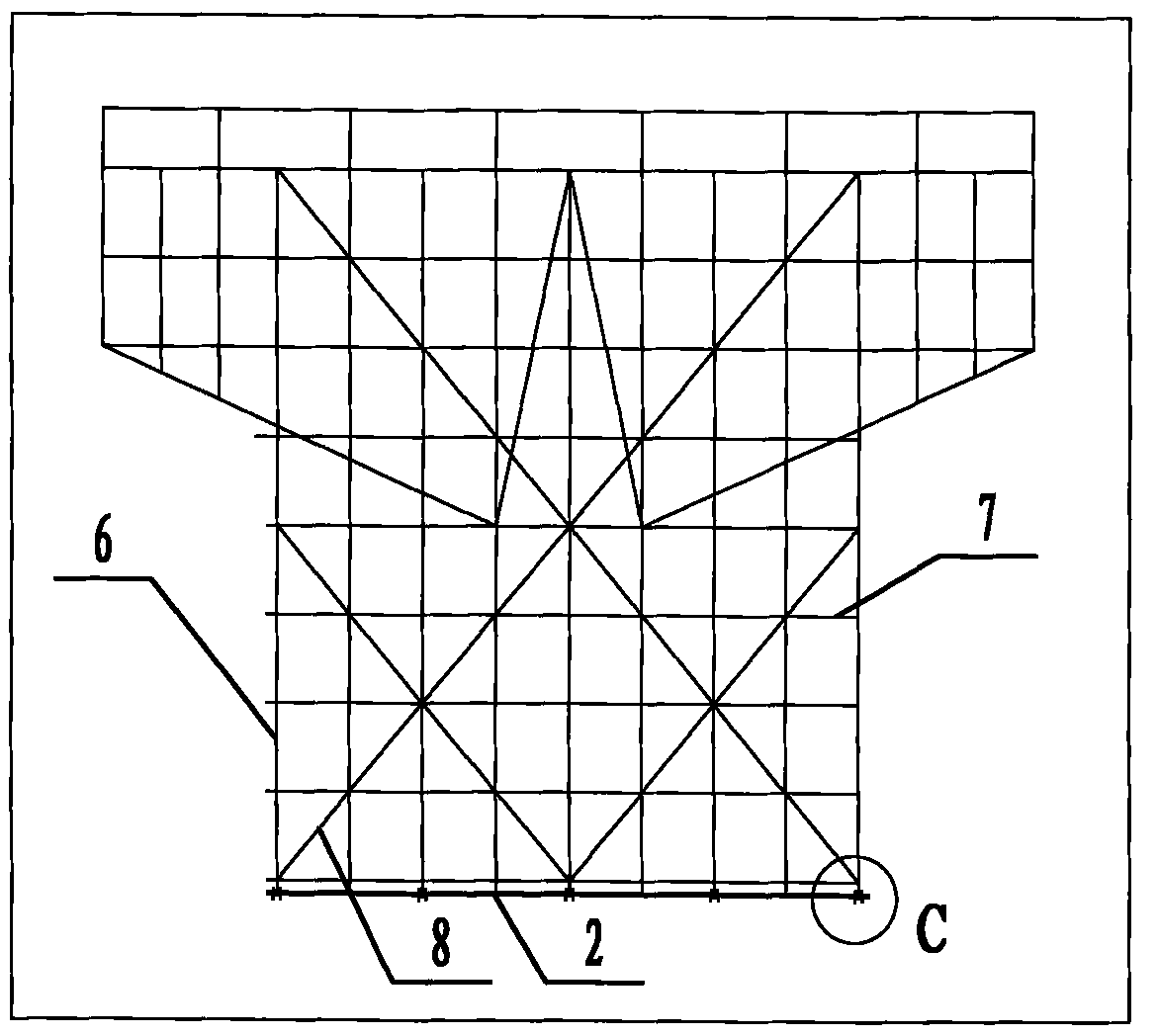

[0034] The middle machine room is a reinforced concrete structure, with corbels as supporting points, and the workshop is a grid ...

example 3

[0040] Project example 3: Painting workshop project in marine area of CSSC Longxue shipbuilding base (construction date: January 2009-October 2009)

[0041] The project is divided into two areas according to functions: sandblasting room and painting room. The sandblasting room includes three intermediate machine rooms, one rear machine room, and two sandblasting rooms. The crane single-storey factory building has a plane axis size of 24m×42m; the painting workshop includes four intermediate machine rooms and three painting rooms. The total axis size is 42m×120.7m, and the main workshop is a single-storey factory building without a crane, and its plane axis size is 24m×42m. The structure of the middle machine room and the rear machine room of the painting room and sandblasting room are all reinforced concrete frame structures, with a total area of 9818m2 2 , with a total construction area of 15743m 2 , of which the blasting room is 7921m 2 , paint booth 7822m 2 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com