Bearer for gliding reticulated shell

A technology of support and sliding, which is applied in the direction of construction and building structure, can solve problems affecting construction, safety, quality hidden dangers, and structural strength effects, and achieve the effects of ensuring construction safety, shortening construction time, and ensuring installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

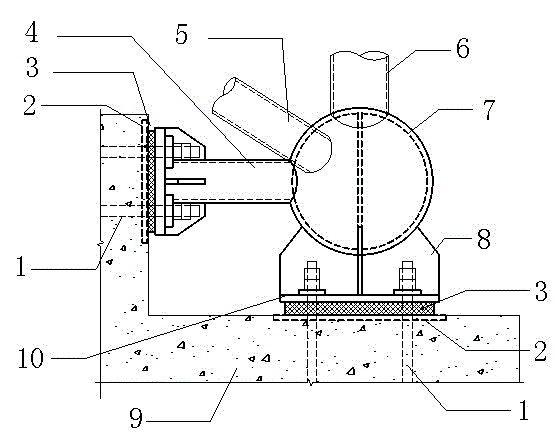

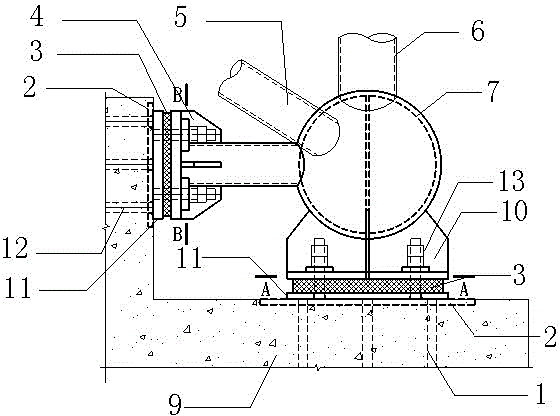

[0039] In the bearing used for reticulated shell sliding in the present invention, the lateral support 4 and the vertical support 10 are arranged adjacent to each other, and jointly support the bearing ball 7, and the bearing ball connects the reticulated shell web 5 and the reticulated shell chord 6. Including the top plate and transition plate of the embedded bearing support surface.

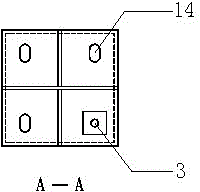

[0040] see now Figure 2-Figure 4 , figure 2 It is a schematic diagram of the support structure of the reticulated shell according to the embodiment of the present invention, image 3 for figure 2 Middle A-A sectional view shows that backing plate 3 and base plate 14 are not welded, Figure 4 for figure 2 Middle B-B sectional view shows that backing plate 3 and base plate 14 are not welded. As shown in the figure, the top plate of the supporting surface of the pre-embedded support is an ordinary pre-embedded steel plate, the thickness of the steel plate shall not be lower than the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com