Prefabricated concrete wall panel installation and emplacement orientation adjustment device and construction method thereof

A prefabricated concrete and adjustment device technology, which is applied in construction, building structure, and building material processing, can solve the problems of precast concrete wall panels that are difficult to quickly and accurately place and adjust, and achieve good promotion value, easy operation, and structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

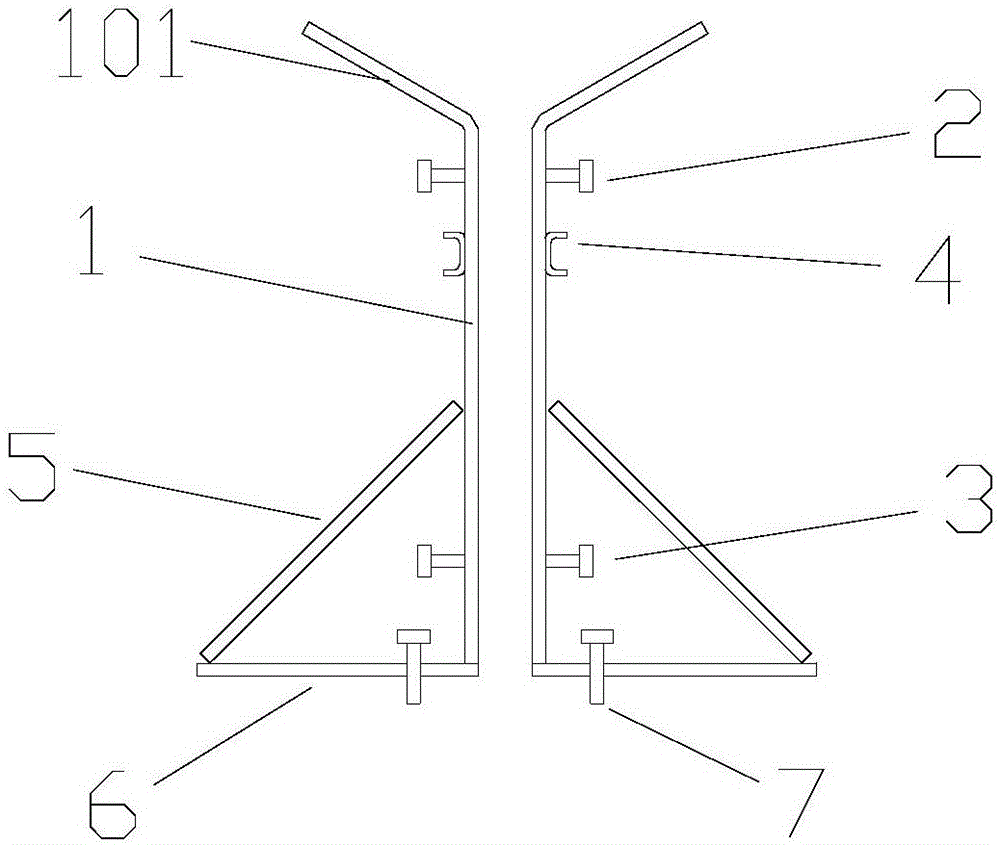

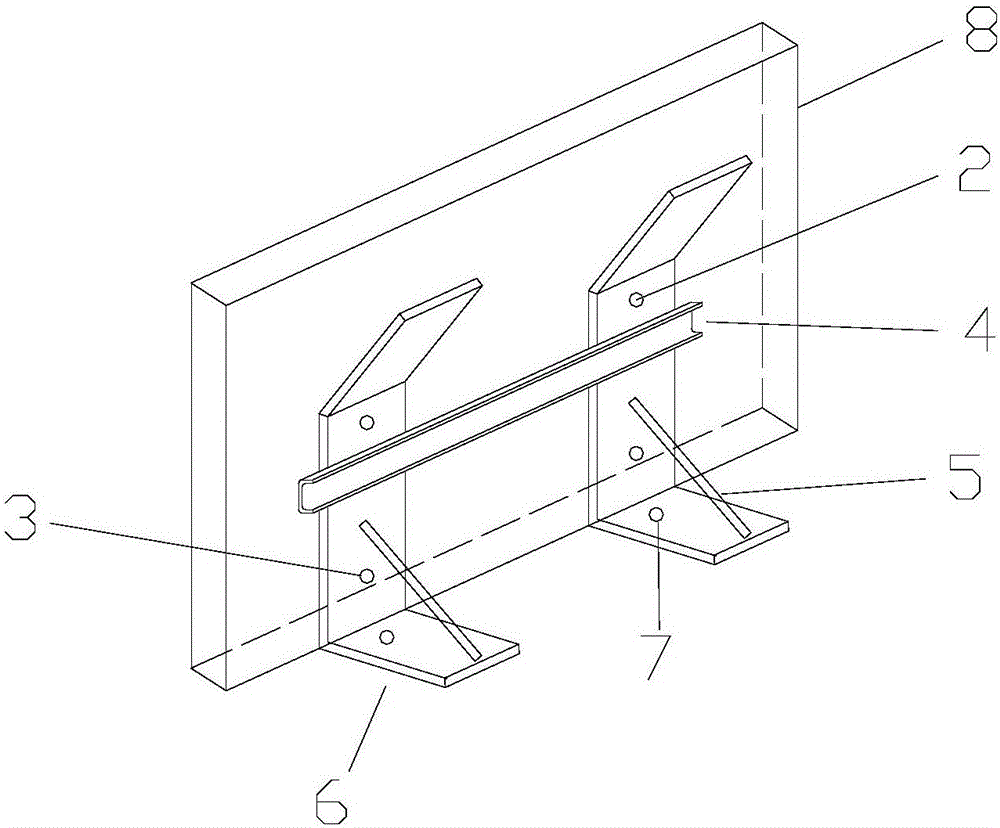

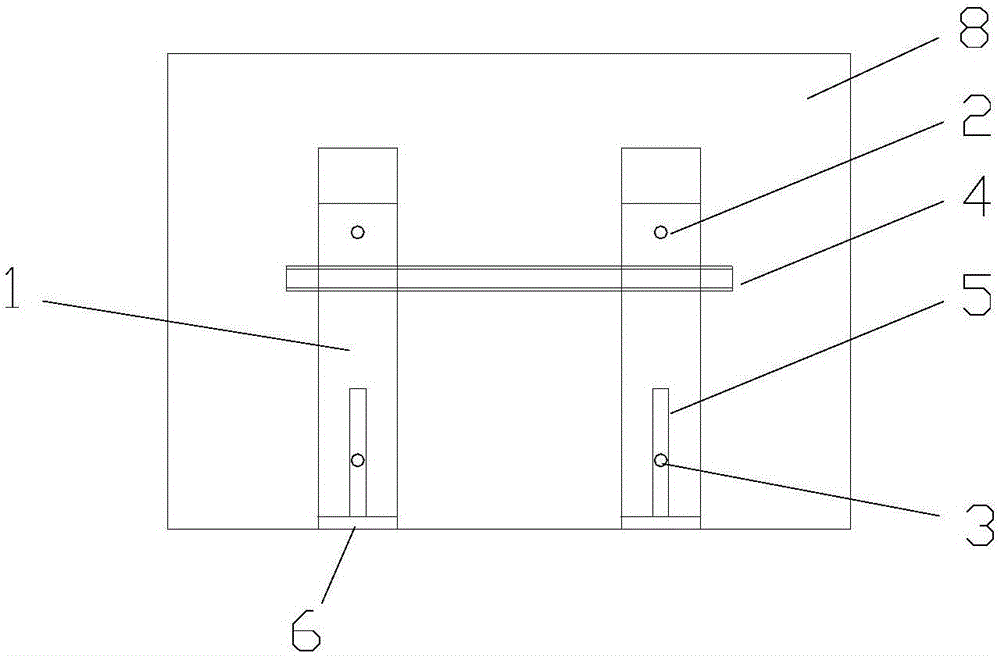

[0029] see Figure 1 to Figure 4 , detailing the structural composition of the precast concrete wall panel installation guide adjustment device of the present invention.

[0030] Such as Figure 1 to Figure 4 As shown, a prefabricated concrete wall panel installation guide adjustment device includes a "funnel-shaped" structure formed by a riser 1 and a base 6, and the riser 1 includes an upper bent part 101 and a lower vertical part (not shown) , the bottom end of the riser 1 is fixed vertically on the base 6, the base 6 is fixed on the floor slab (not shown) through embedded bolts, and the two risers on the same side of the precast concrete wall plate 8 are connected by The rods 4 are fixed and form a cavity capable of receiving a precast concrete wall panel 8 .

[0031] Specifically, in the guide adjustment device for installing precast concrete wall panels in place according to the present invention, the two vertical panels on the same side of the precast concrete wall pa...

Embodiment 2

[0036] Please continue to refer Figure 1 to Figure 4 , the embodiment of the present invention provides a construction method for installing a guide adjustment device in place for a precast concrete wall panel. The construction method includes the following steps:

[0037] Step 1: Provide several prefabricated concrete wall panel installation guide adjustment devices for backup;

[0038] Step 2: Position and set out the installation position of the precast concrete wall panel on the floor slab, install the precast concrete wall panel in place according to the line setting position, install the in-position guide adjustment device, and fix it on the floor slab;

[0039] Step 3: Use a tower crane to hoist the precast concrete wall panel 8 above the position to be installed. With manual assistance, the precast concrete wall panel 8 will accurately arrive at the position to be installed along the upper bending part of the vertical plate 1. Adjust the screw rod (2 ,3) Adjust the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com