Large-span overhead pipeline sliding installation method

An overhead pipeline, large-span technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, machinery and equipment, etc., can solve problems such as inconvenience, construction and installation difficulties, hoisting operations, etc., to ensure construction safety and installation quality. , The effect of reducing installation and construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

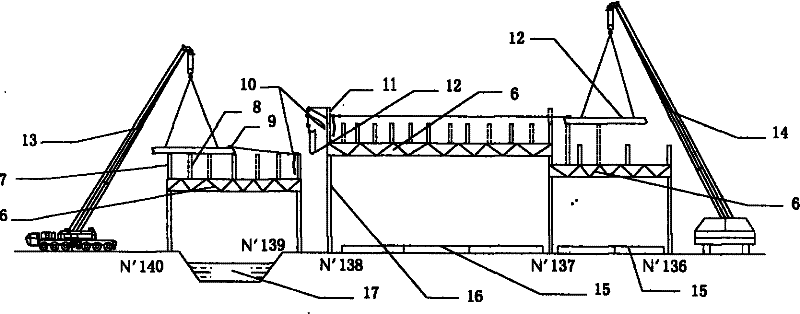

[0024] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

[0025] The sliding installation method of the large-span overhead pipeline of the present invention has been successfully applied in the matching power main pipeline project in the tidal flat area of Baosteel.

[0026] The sliding installation technology for large-span overhead pipelines of the present invention includes the following installation steps according to the feature that newly-built pipelines and supports are installed on the original trusses:

[0027] a) Make new brackets and temporary brackets

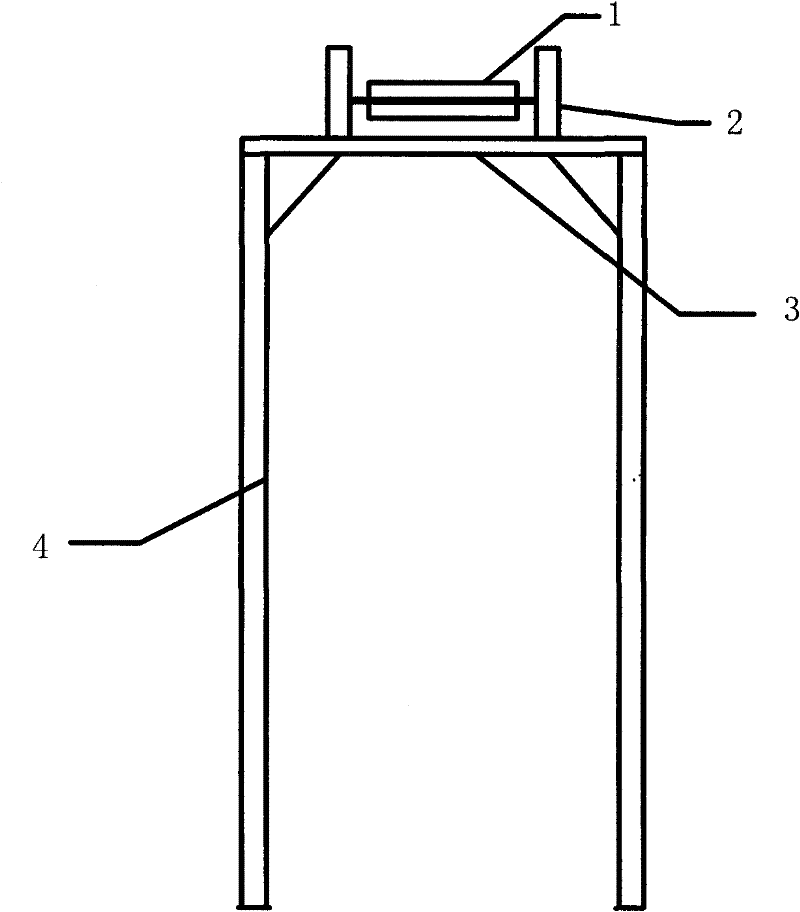

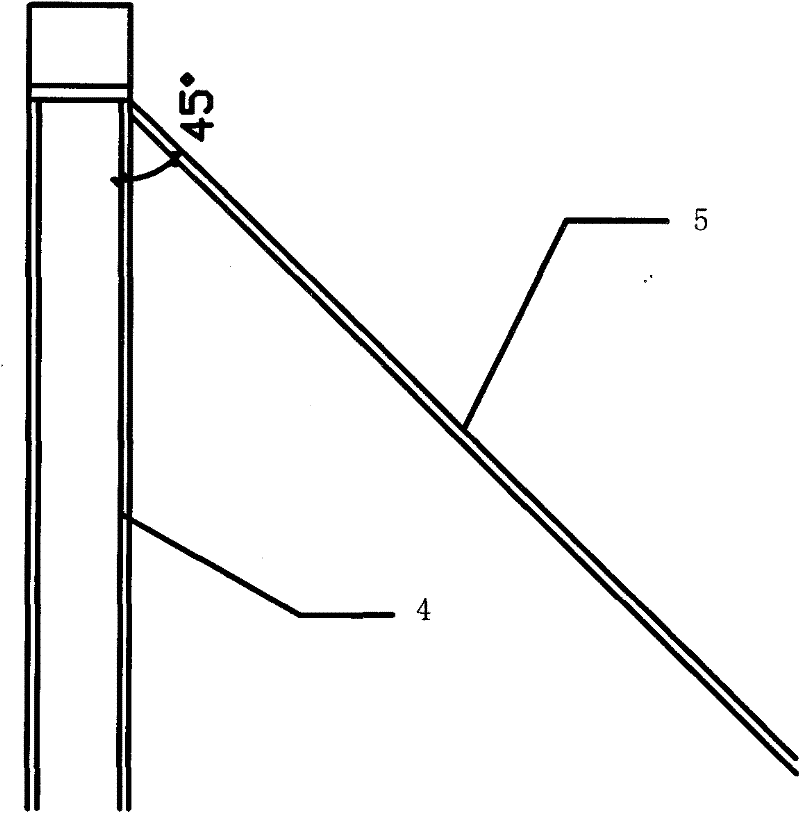

[0028] see now figure 1 with figure 2 , figure 1 It is a structural schematic diagram of a new support and a temporary support according to an embodiment of the present invention, figure 2 It is a schematic diagram of a support brace and a support column according to an embodiment of the present invention. As shown in the figure, provide 10 desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com