Fabricated section-adjustable formwork system for square stiff pillars and construction method of fabricated section-adjustable formwork system

A prefabricated, stiffened column technology, applied in formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of reducing the diameter of the concrete square stiffened column section, strengthening and dismantling the formwork system The workload is large, the pull screw cannot be used in turnaround, etc., to achieve the effect of good physical quality, significant economic and social benefits, and flexible and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

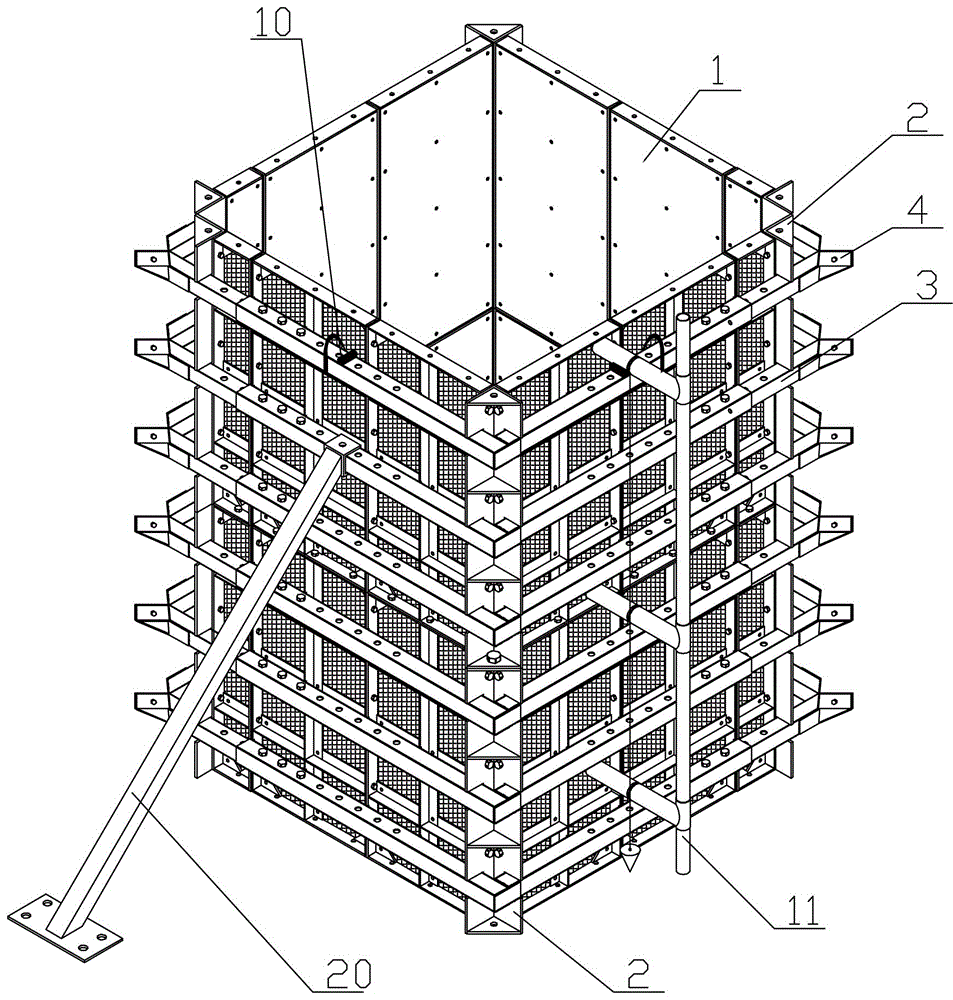

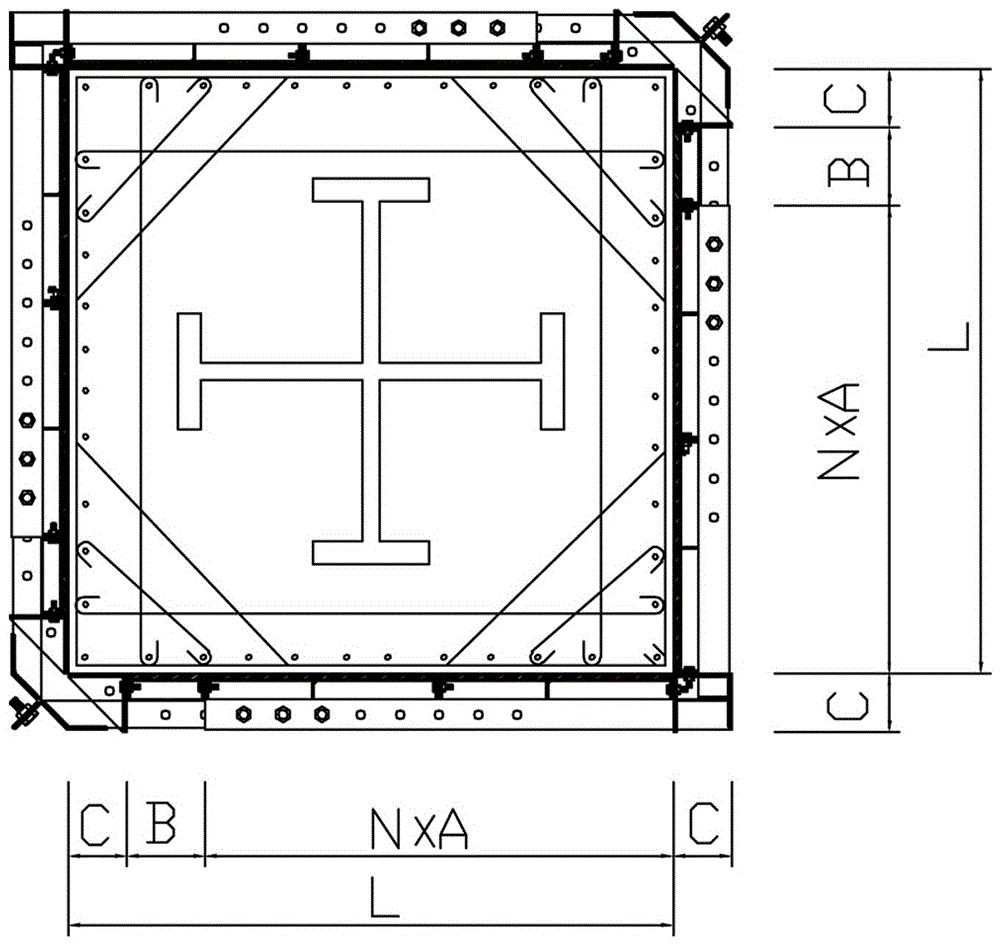

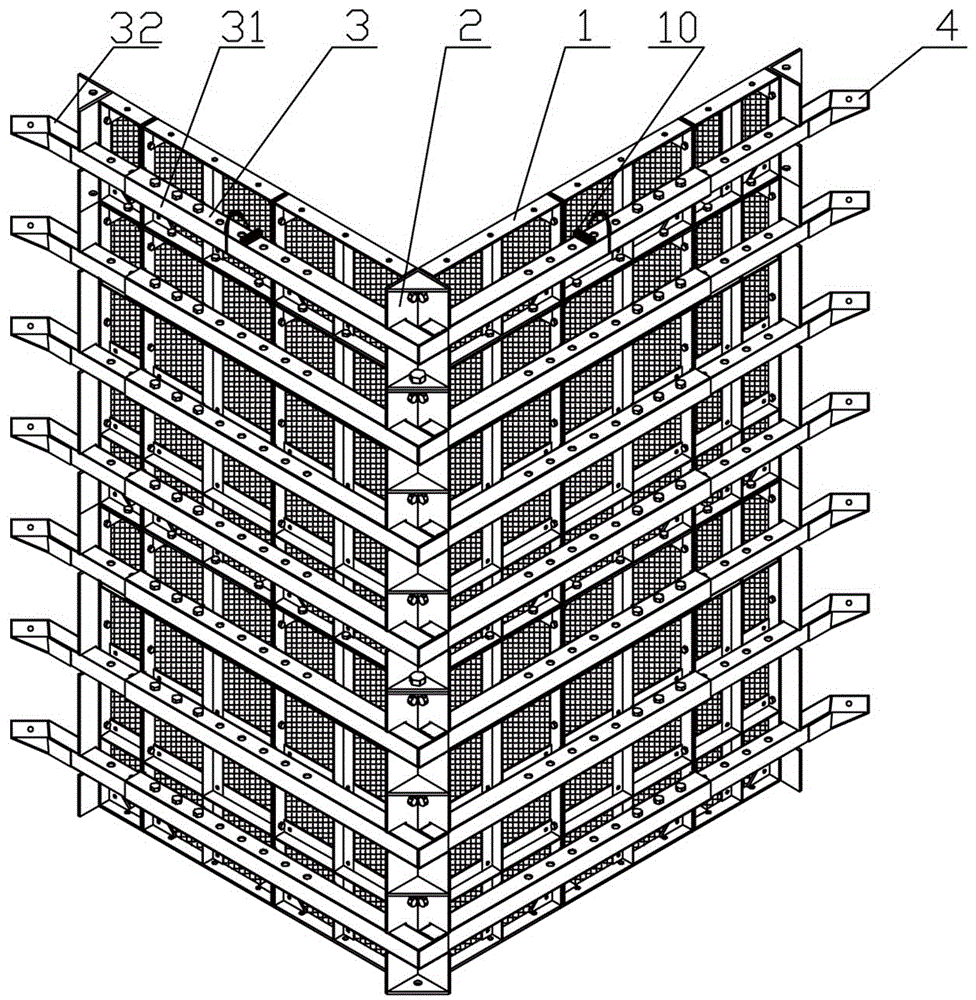

[0023] like Figure 1 to Figure 3 As shown, a square rigid column assembly type adjustable section formwork system, a rectangular structure composed of four face formwork 1, each two face formwork 1 is connected by an angle steel positioning piece 2, and the vertical angle steel positioning piece 2 is connected. There are several evenly distributed rectangular grooves in the direction, and a number of limit beams 3 are arranged on the outer surface of the surface formwork 1. The limit beam 3 is connected vertically; the surface formwork 1 is composed of several standard unit formwork and a non-standard unit formwork connected to each other. The standard formwork and the non-standard formwork are composed of angle steel, corner code and formwork, and the periphery is sealed with a hole frame. It is convenient for the two unit templates to be connected to each other; the limit beam 3 is composed of the outer square steel 31 and the inner square steel 32 plugged together. The le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com