Combined eave system with large-span steel structure and bracket system wood structure and construction method of combined eave structure

A wooden structure and bucket arch technology, which is applied to roofs, roofs, and roofs using tiles/slate tiles, can solve the problems of eaves shape, complicated process, many special-shaped components, and large overhang length, so as to achieve standardization of installation technology and improve The effect of improving work efficiency and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

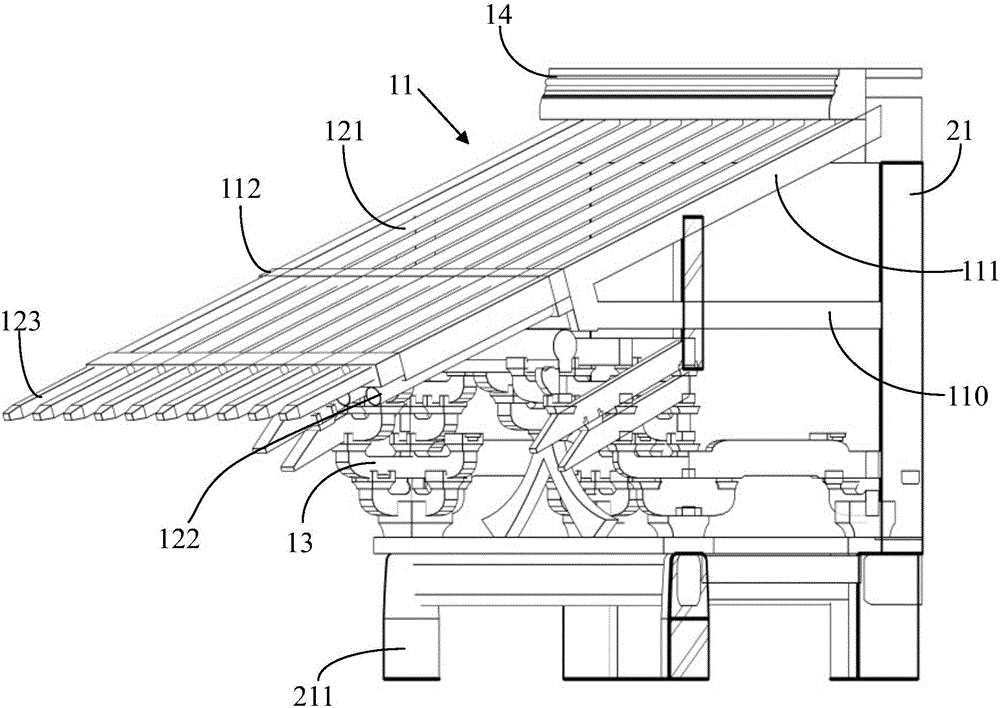

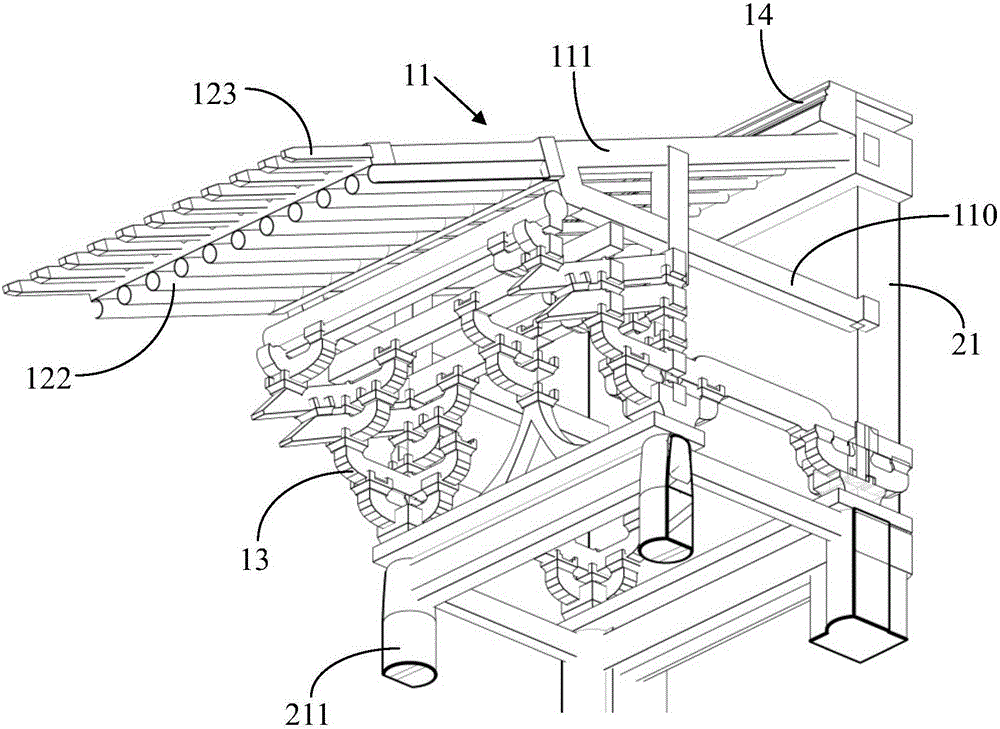

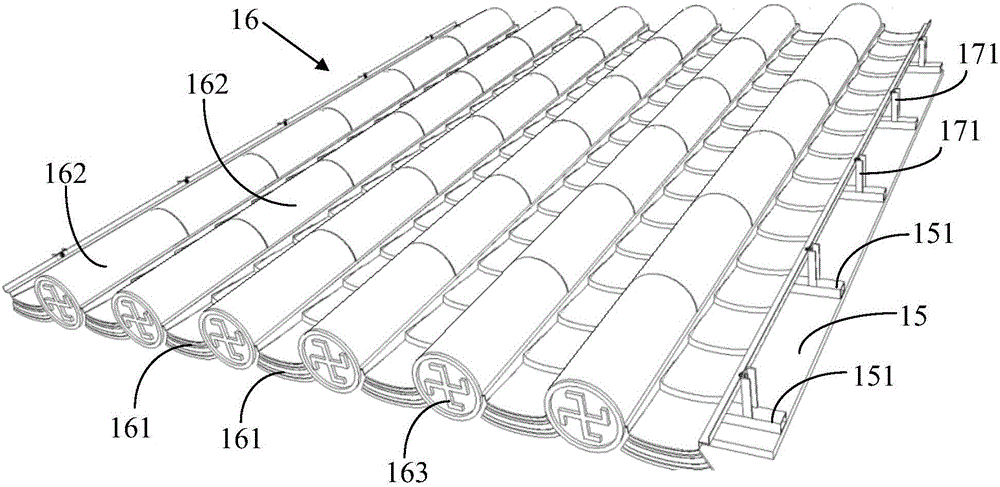

[0056] see first Figure 1~3 As shown, the combined eaves system of the present invention's long-span steel structure and bucket arch wood structure mainly consists of figure 1 and figure 2 Shown main structure steel frame 11, secondary steel structure, bucket arch wooden structure 13, roof ridge structure 14, and as image 3 The eaves panel 15 and roof tile structure 16 are shown. Make full use of the performance and advantages of steel and wood to form a reasonable and stable structural framework, accurately and completely grasp the artistic effect of ancient buildings, and improve the impermeability of the roof system.

[0057] The main structural steel frame includes a cantilevered steel frame that is cantilevered and connected to the roof structure 21, and a supporting steel beam 110 that is connected between the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com