Verticality adjustment system for lattice column correcting mount and construction method thereof

A construction method and a technology for calibrating the frame, which are applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of difficult construction of inverse slabs, increased length of lattice columns, and difficult to control verticality, so as to increase cost consumption, The effect of easy operation, saving labor and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

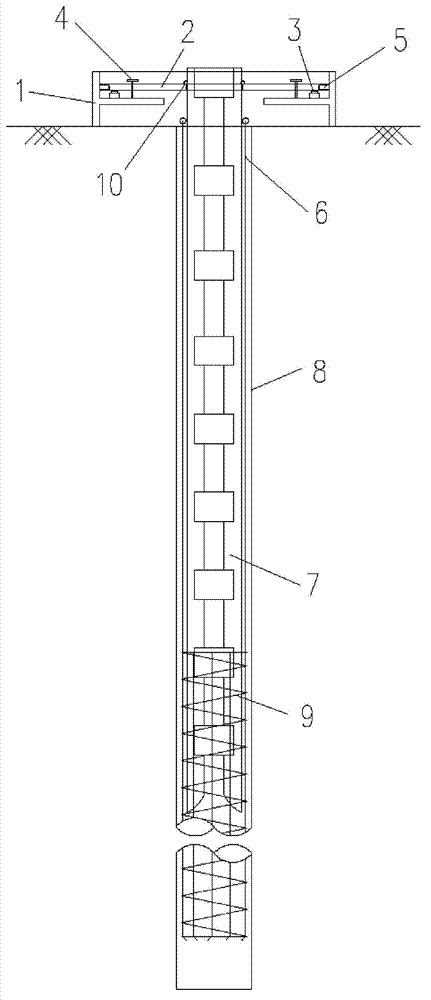

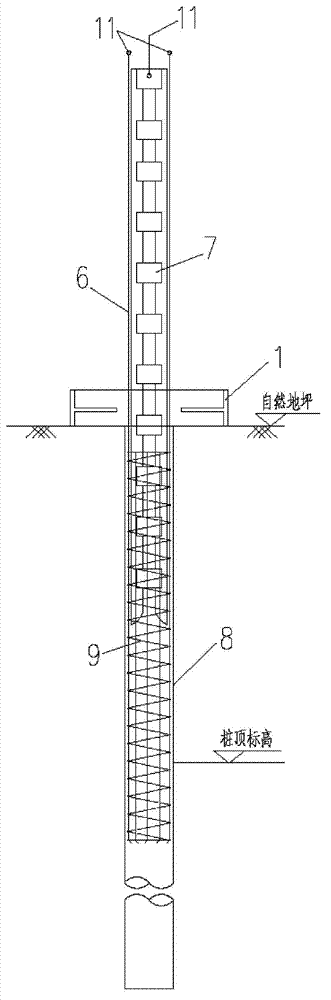

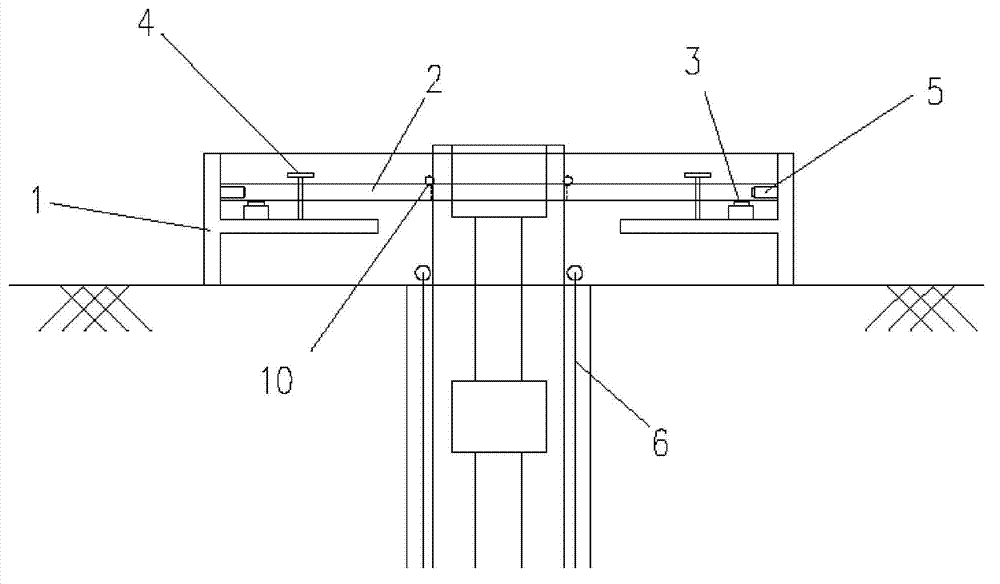

[0028] see figure 1 , figure 2 , image 3 , Figure 5 The vertical adjustment system of the lattice column correction frame shown in Figure 4 and the schematic diagram of the vertical adjustment construction method shown in Figure 4 are proposed by this patent.

[0029] The positioning frame 1 is made of steel components and is located at the bottom and side of the calibration frame 2; the calibration frame 2 is also composed of steel components. The vertical adjustment system also includes a support screw 4, a vertical jack 3, and a horizontal jack 5. The support screw 4 is screwed into the correction frame 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com