Construction method of simply supported-continuous switching system of negative moment beam prestressed precast box beam

A technology of simple support first and then continuous construction method, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as unpublished, inability of connecting body to adapt to structural stress changes, structural hidden dangers, etc., to improve construction efficiency , The effect of facilitating safe and civilized construction management and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

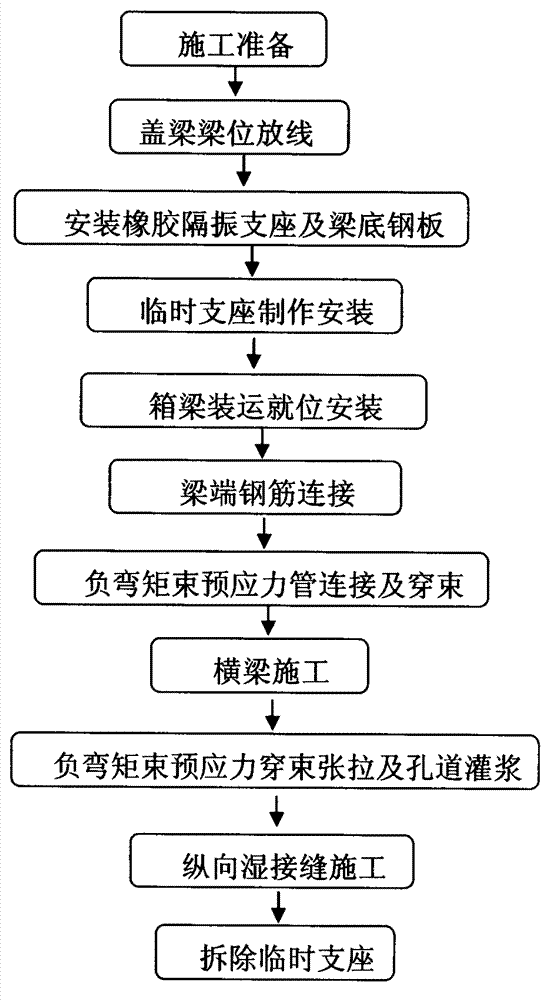

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] The construction method of the negative moment beam prestressed prefabricated box girder of the present invention is first simply supported and then continuously converted. Shipment and installation of box girders, steel bar connection at beam ends, negative moment beam prestressed tube connection and beam penetration, beam construction, negative moment beam prestressed beam penetration tensioning and tunnel grouting, longitudinal wet joint construction and removal of temporary supports seat.

[0011] In the foregoing, the essential feature of the present invention’s construction method of the negative moment beam prestressed prefabricated box girder is simple support first and then the continuous conversion system is that the upper main girder structure is firstly prefabricated in the factory, and after the temporary support is installed, the main girder is ere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com