Sub-surface defect shape reconstruction method for thermal imaging detection

A sub-surface defect and thermal imaging technology, applied in the direction of material defect testing, etc., to achieve the effect of quantitative analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

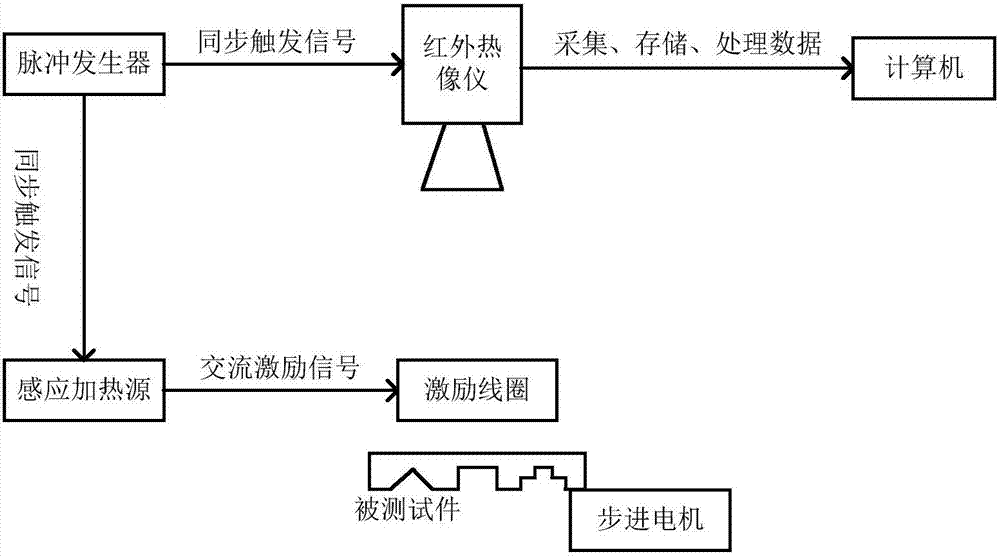

[0028] figure 1 It is a schematic diagram of the structure of the infrared thermal imaging non-destructive testing system.

[0029] In this example, if figure 1 As shown, the infrared thermal imaging non-destructive testing system usually consists of four parts: (1) thermal excitation part (induction heating source and excitation coil); (2) infrared thermal image acquisition part (infrared thermal imager); (3) control test Part moving part (stepping motor); (4) infrared thermal image processing and analysis part (computer); in addition, it also includes a pulse generator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com