Foundation post-pouring belt template constructing method

A construction method and technology of post-pouring belts, applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of difficult formwork removal, inability to reuse, difficult to clean, etc., to achieve clean and civilized construction management, easy to civilized construction management , cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention. Therefore, the examples cited do not limit the protection scope of the present invention.

[0024] The construction method of the foundation post-cast belt template in this embodiment is carried out according to the following steps:

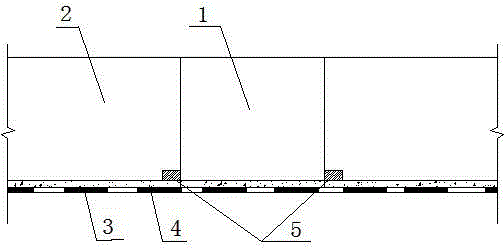

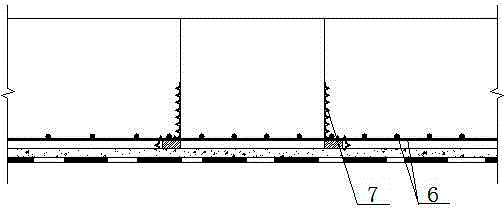

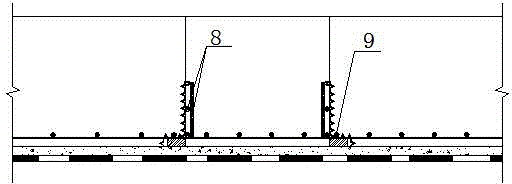

[0025] ① Pouring concrete strip 5. After the foundation waterproof protection layer 4 is completed, the position line of the post-pouring belt 1 is popped up on the cushion layer, and the concrete strips 5 with the same number as the foundation are pre-poured along both sides of the post-pouring belt 1 along the line. The width is 100 mm and the height is the same as the steel protection. Layer thickness, and moisture conservation (see figure 1 ). The functions of the concrete strip 5 are as follows: one is to serve as a protective layer for the steel bars of the bottom plate; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com