Method for rapidly detecting accuracy of position seaming in shipbuilding process

A precision and fast technology, applied in ship parts, ship construction, ships, etc., can solve problems such as misalignment of ribs, misalignment of pier side plate girders, cutting and repairing, etc., to improve accuracy and speed, and reduce cutting and repairing The effect of saving workload and hoisting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

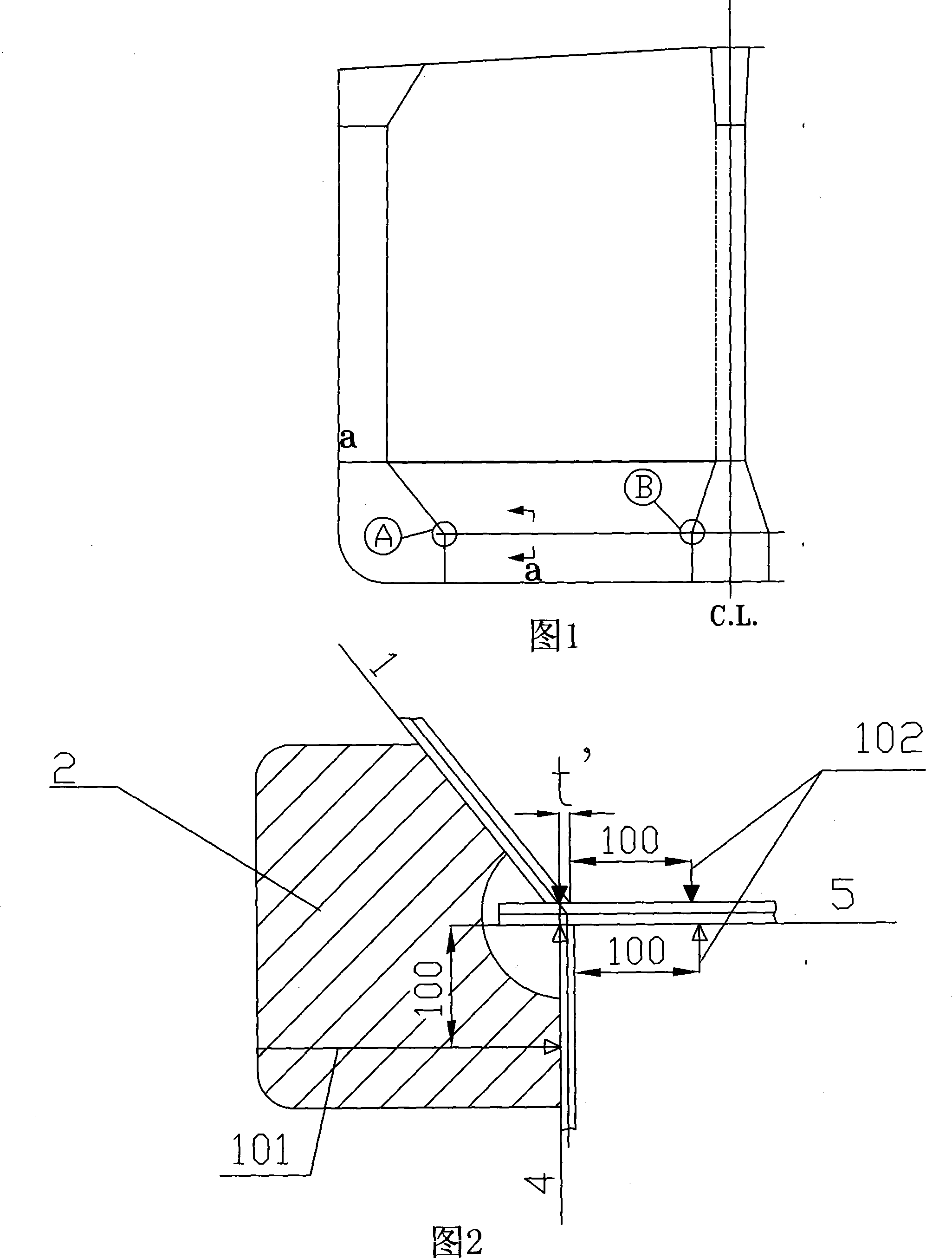

[0030] A schematic cross-sectional view of a typical cargo hold area as shown in Figure 1.

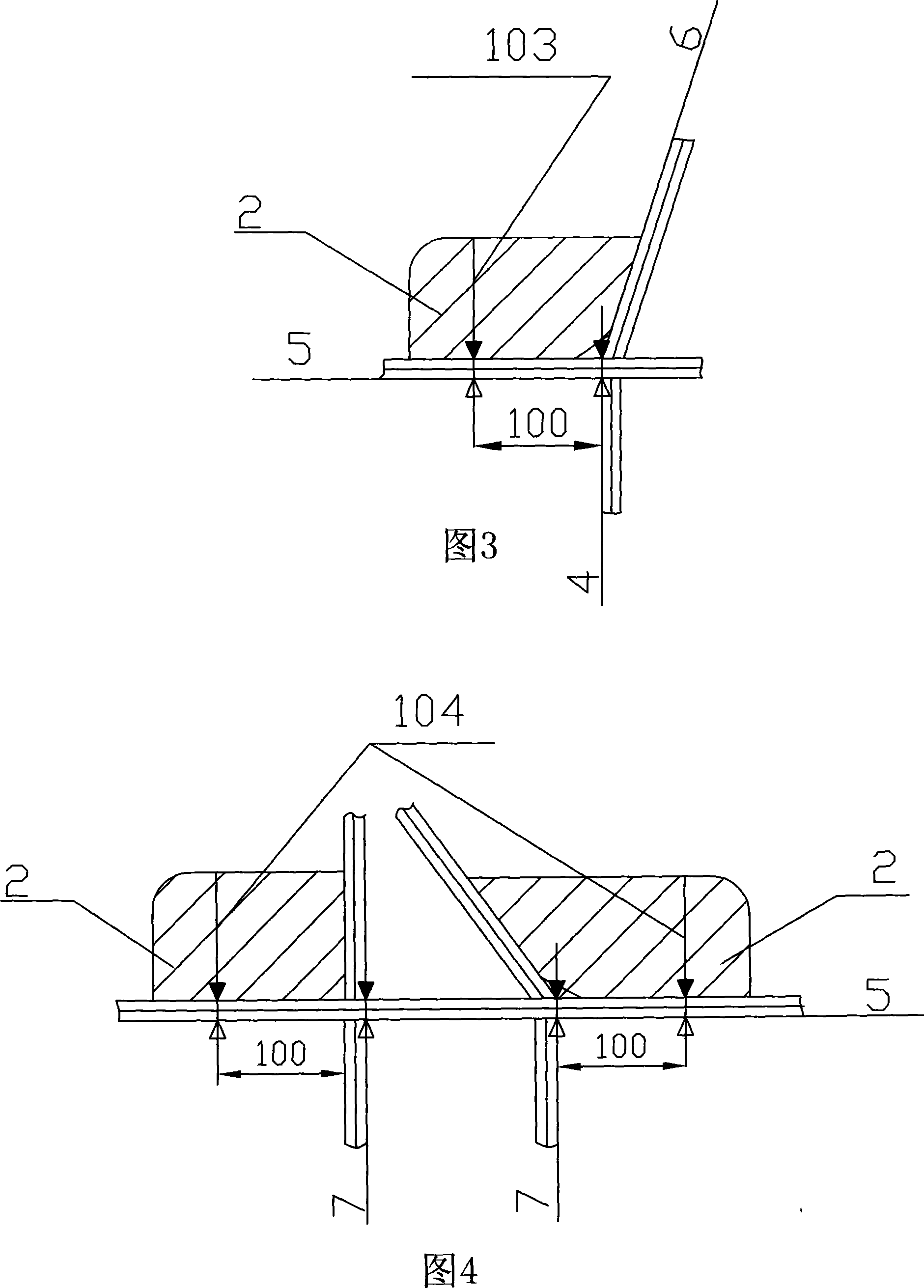

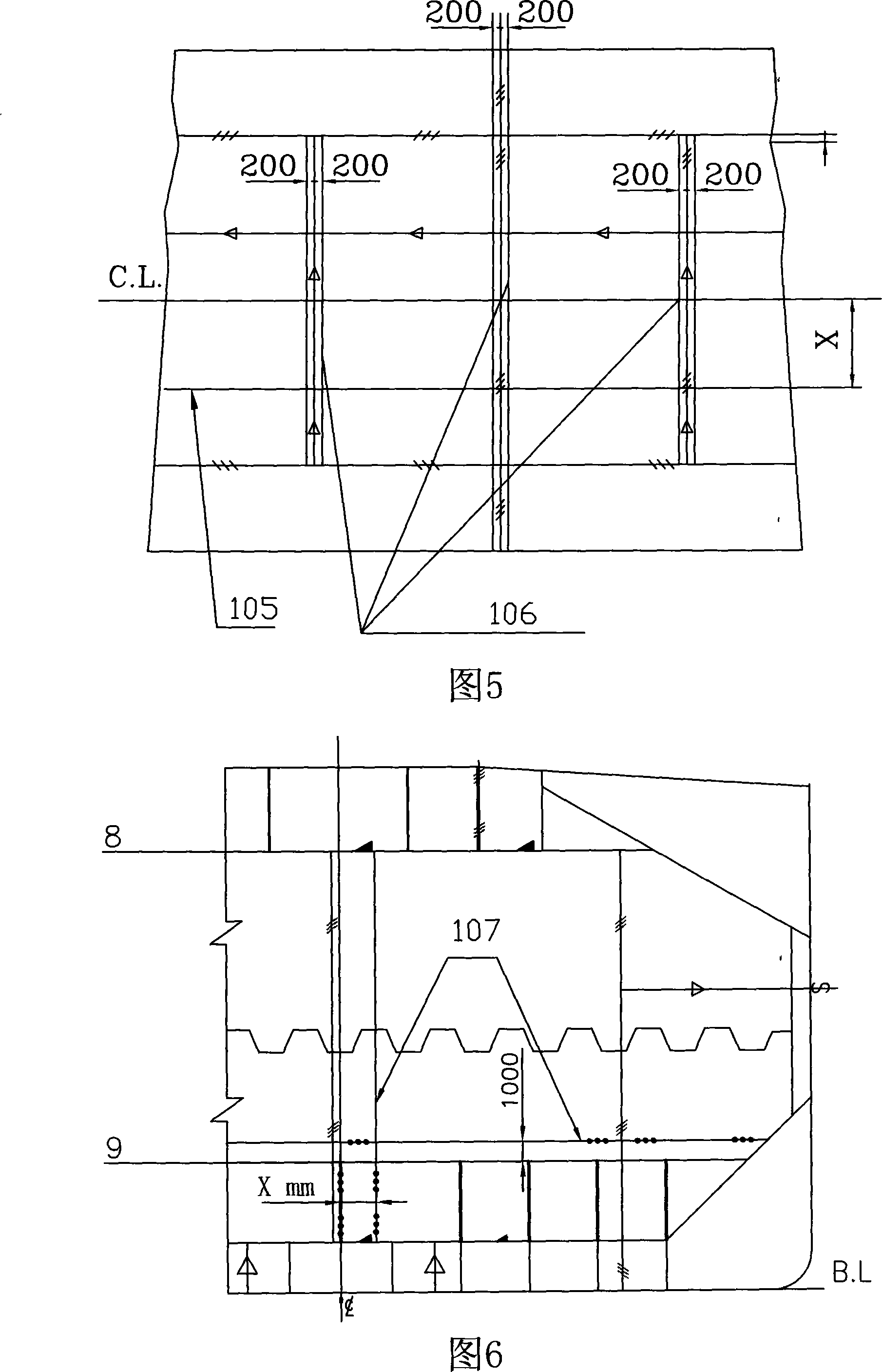

[0031] Usually, in the process of shipbuilding, before closing, the plates or trusses to be closed are pre-marked on the plate-to-plate, plate-to-truss, and truss-to-truss connection positions, or at least pre-determined that the plates or trusses will be Connect to each other based on that boundary surface or boundary line. Here, these pre-marked connection positions or boundary surfaces or boundary lines serving as connection references are referred to as "connection baselines". Method of the present invention just utilizes these " connecting base lines ", before positioning and closing up, be positioned at the side of connecting base line on plate or truss and set another " reference line " parallel to connecting base line with equidistant; Thus when positioning closes up, These "reference lines" are used to detect the accuracy of closing, and these "reference lines" can also be us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com