Method for scribing integral cylinder block blanks of large diesel engines

A technology of integral cylinder and cylinder block, which is applied to the parts of boring machine/drilling machine, the measurement of positioning in boring machine/drilling machine, drilling/drilling equipment, etc. Avoid quality hazards and other problems, achieve the effects of avoiding safety and quality accidents, high marking accuracy, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

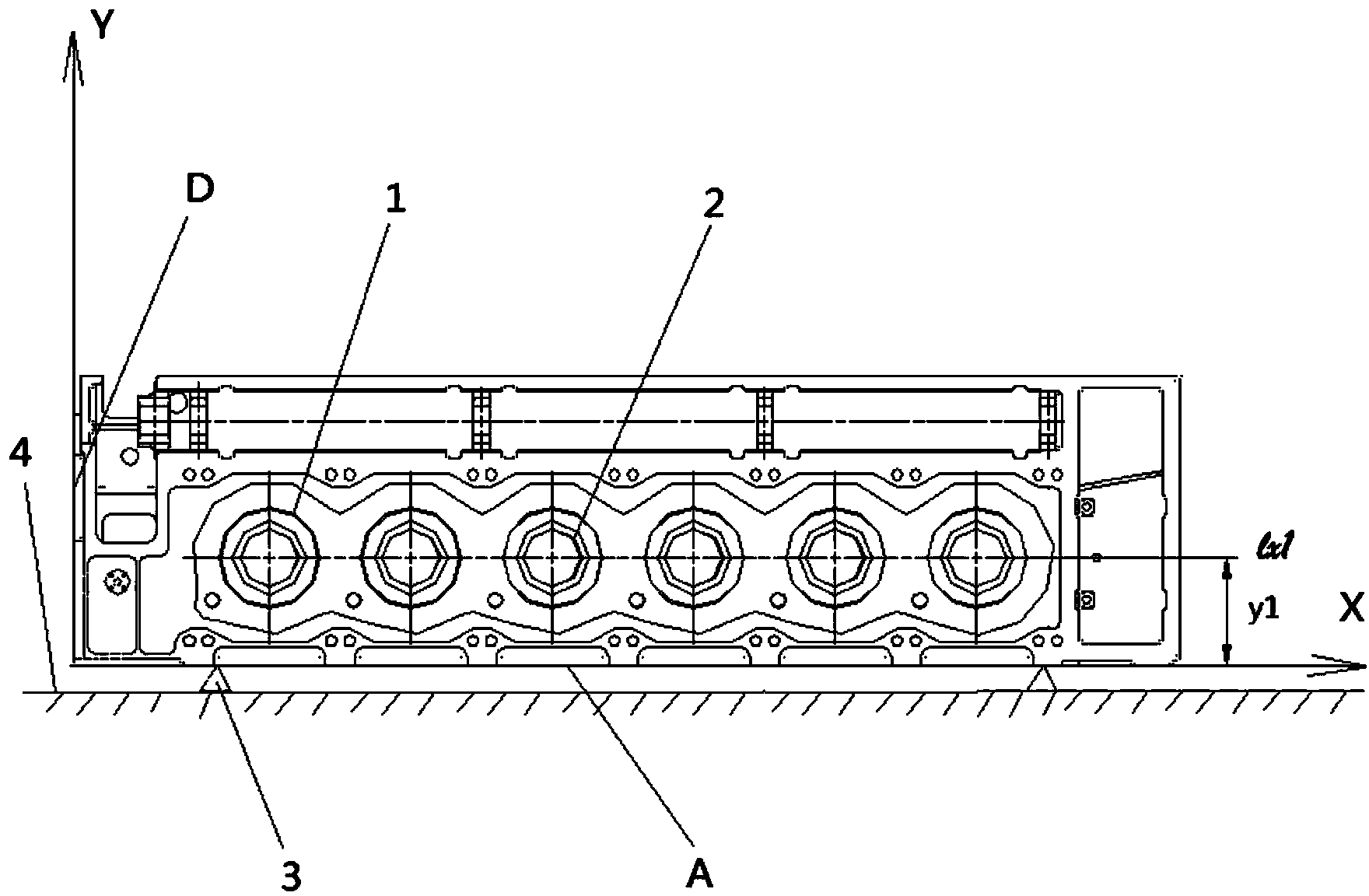

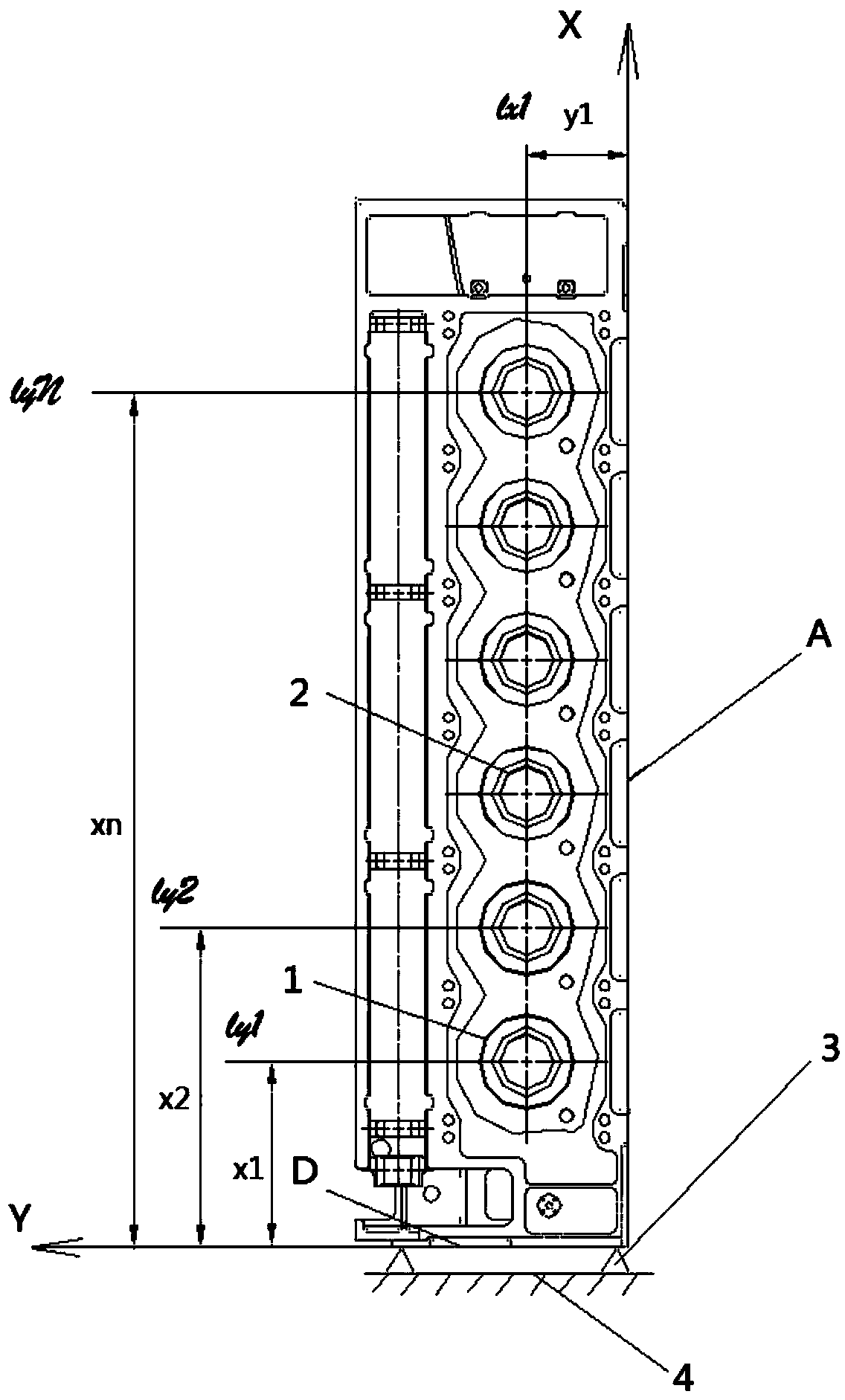

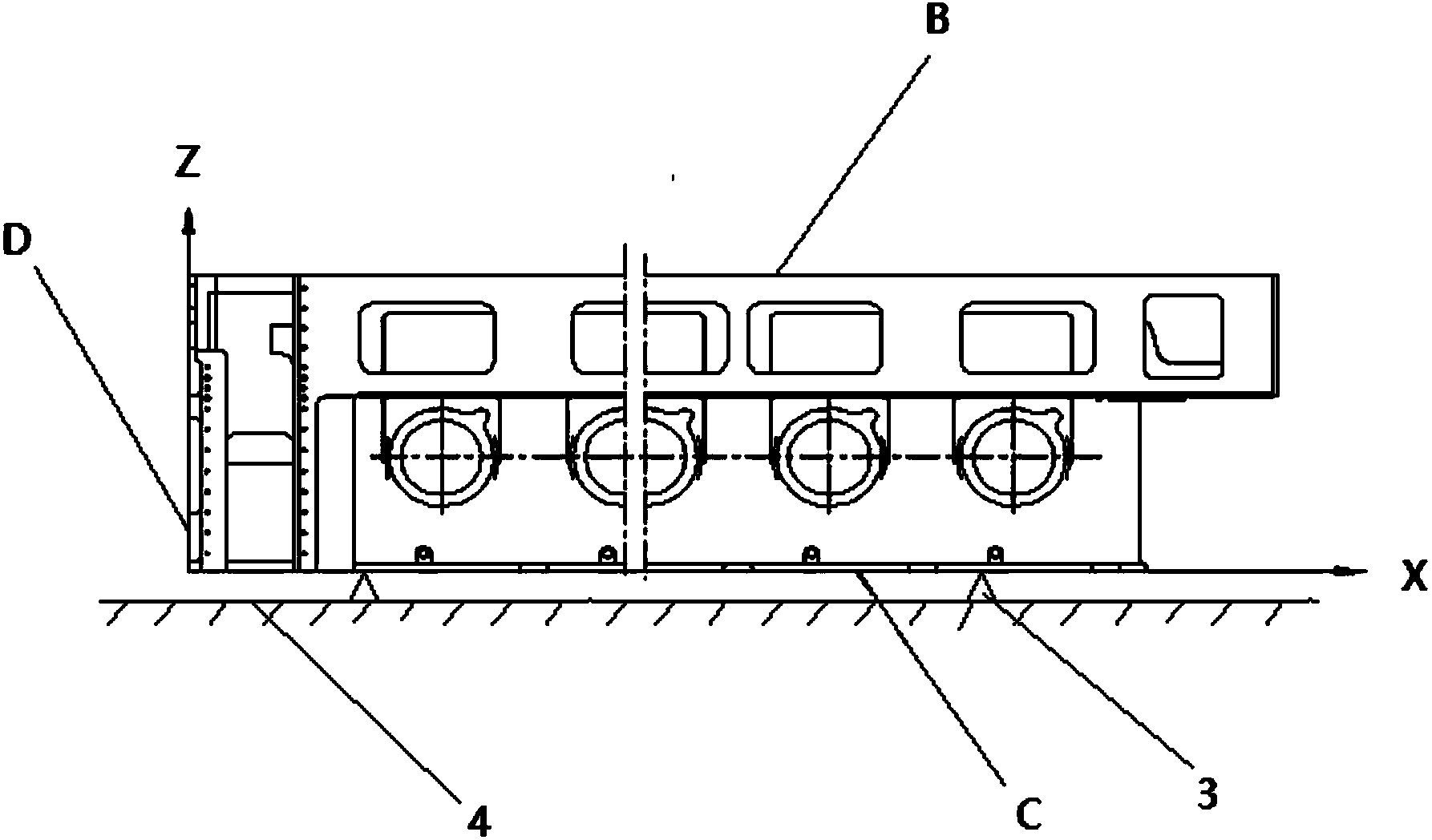

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

[0030] The key to solving the technical problem of the present invention is how to draw the centerlines of the cylinder liner holes and the grid holes and their reference end faces on the horizontal position of the cylinder block blank under the premise of ensuring the machining allowance. Location.

[0031] According to the present invention, a method for scribing lines for the integral cylinder block blank of a large diesel engine, the cylinder block blank has several groups of coaxial cylinder liner blank holes and gland blank holes, and is characterized in that: on the premise of ensuring the machining allowance Next, complete the three-dimensional space marking task in the form of two-dimensional marking, use the two marking positions of the cylinder block blank o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com