Construction method for building postposition pre-buried wall connecting parts

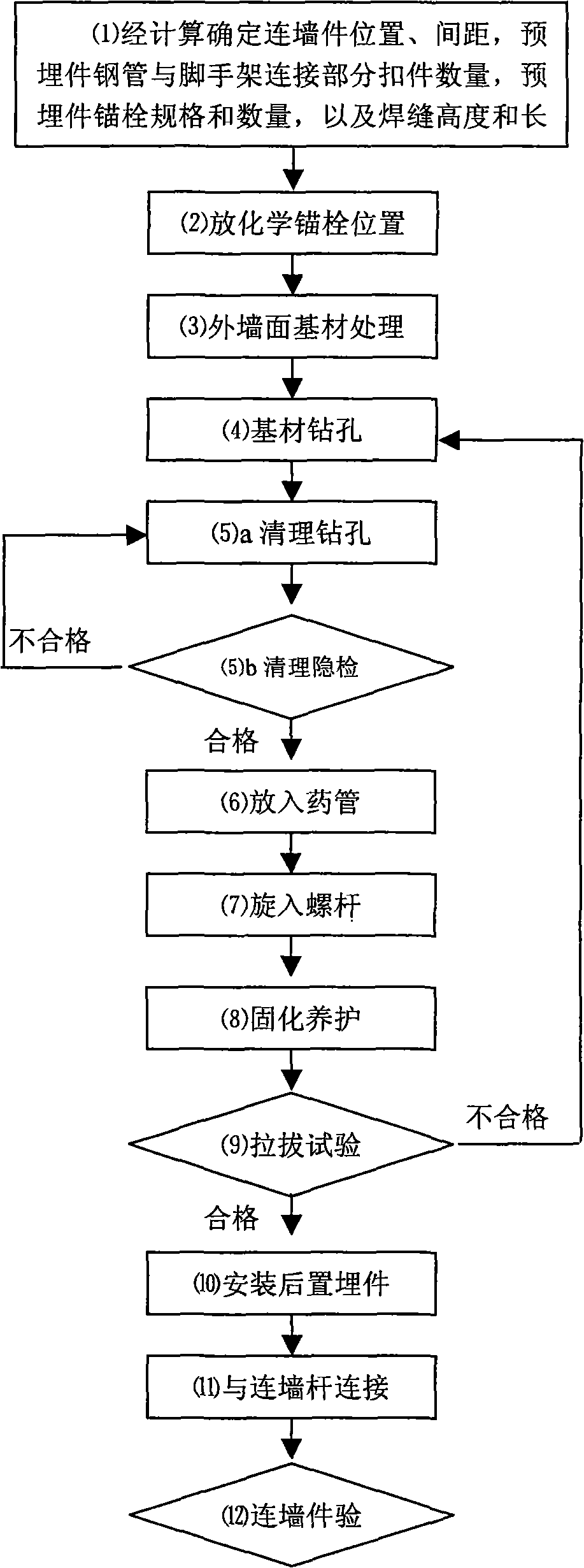

A construction method and a technology for connecting wall parts are applied in the field of construction of post-embedded wall connecting parts and floor-standing fastener steel pipe scaffolding, which can solve the problem that the fastener type connecting wall parts cannot be used and the turnover of the connecting wall parts is inconvenient. , embedded parts can not be used and other problems, to achieve the effect of easy disassembly and multiple turnover, reduce the risk of random disassembly and modification, and ensure civilized construction and construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

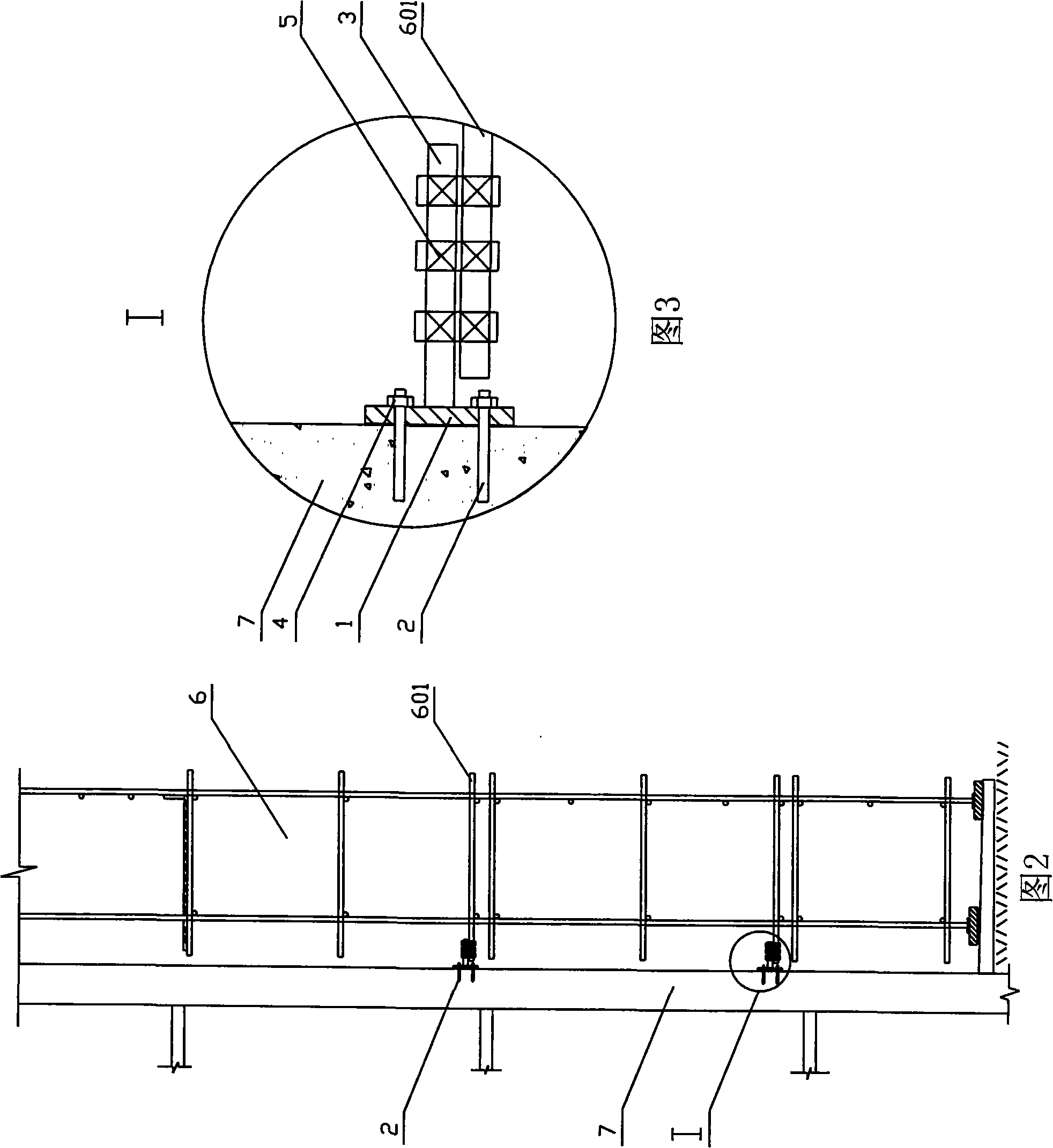

[0063] At the same time, refer to Fig. 2 and Fig. 3. Use oxyacetylene cutting equipment, punching machine, welding machine, welding rod, etc. to weld the short steel pipe 3 of Φ48mm and 600mm in length on the 200×100×10mm steel plate embedded part 1, and punch two Anchor holes pass through chemical anchor bolts 2 that have been anchored on steel structures and concrete building exterior walls 7, and are tightened and fixed by the nuts of connectors 4;

[0064] (11) Connect with the wall rod

[0065] Connect the short steel pipe 3 to the wall bar 601 of the existing floor fastener steel pipe scaffold 6 through the existing single or multiple fasteners 5; When tightening the steel pipe 3, the minimum distance between the openings is less than 5mm, and no damage shall occur when the bolt tightening torque reaches 65N·m;

Embodiment 2

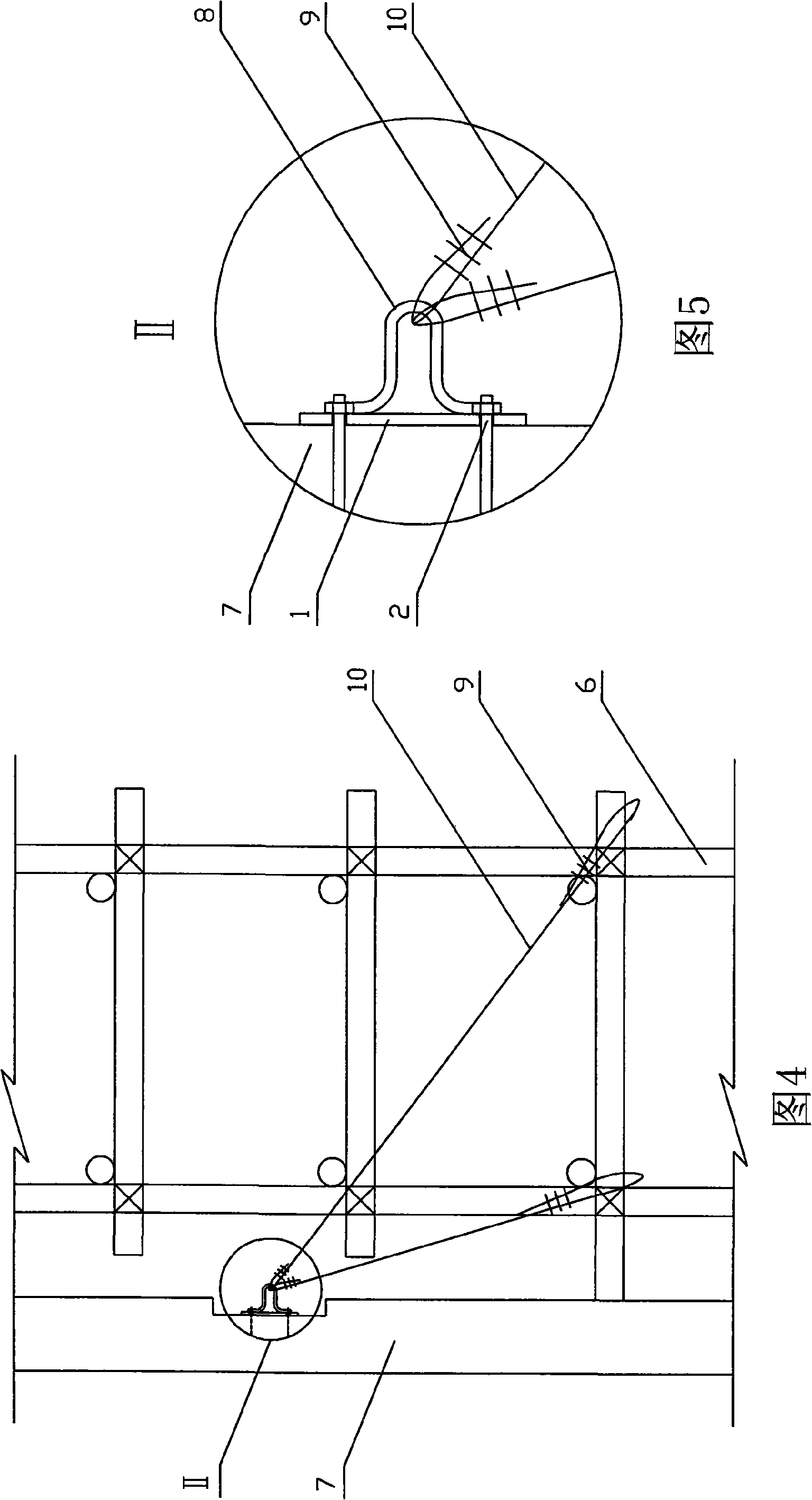

[0067] Referring to Fig. 4 and Fig. 5, when the scaffold 6 needs to be partially unloaded, the size of the steel plate embedded part 1 with the short steel pipe 3 can be increased to 200×200×10mm, and a steel bar made of HPB235 grade and Φ18mm can be added. The lifting ring 8 is welded with the steel plate embedded part 1, the height and length of the weld seam are determined by calculation, and the lifting ring 8 is unloaded through the clamp 9 and the steel wire rope 10 and the scaffold 6;

[0068] (12) Acceptance of wall parts

[0069] a) Check whether the scaffolding construction plan is declared and approved according to the regulations;

[0070] b) Check whether the spacing and position of the setting points of the connecting wall parts are consistent with the plan;

[0071] c) Check whether the processing of post-embedded parts is qualified, and the qualification certificates of various materials;

[0072] d) Check whether the pull-out test results of the chemical bol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com