Device and method for positioning variable-thickness preform and detecting thickness of preform

A thickness detection and prefabrication technology, applied in the field of resin matrix composite material liquid molding, can solve the problems of fiber scouring deformation, parts rich in grease, scouring deformation, etc., to ensure effectiveness and accuracy, reduce molding risks, and ensure positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

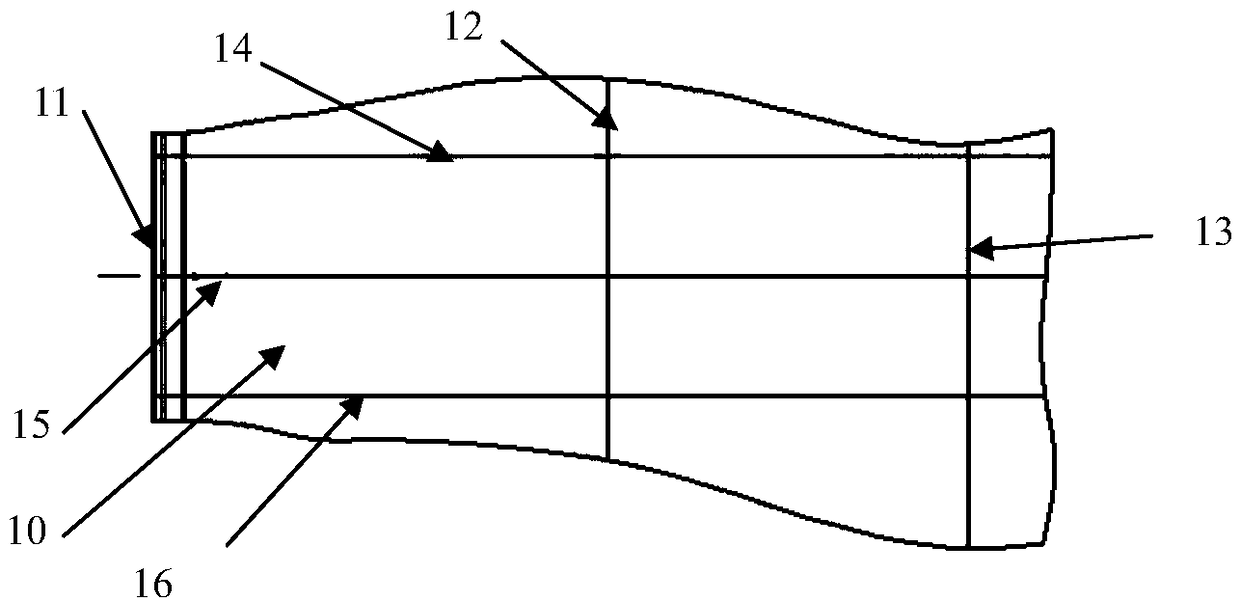

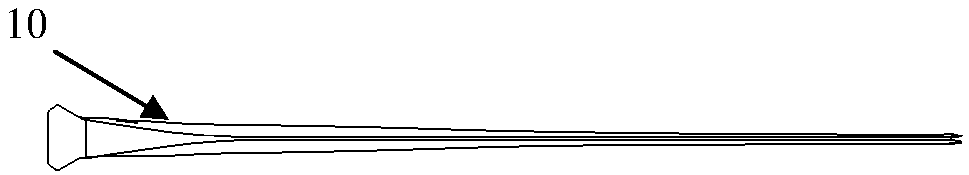

[0061] The prefabricated body 10 to be tested is a fan blade prefabricated body with a variable thickness 2.5D woven structure. The material is CCF800, and the fiber volume content of the material is 55%±3%. Among them, CCF800 is T800 grade carbon fiber with a specification of 12K produced by Shandong Weihai Development Company. The outer dimensions of the fabric and parts are: 750mm×300mm×(1.5~60mm) (length×width×height), and the distances of 0mm, 380mm and 680mm in the longitudinal direction of the surface of the prefabricated body 10 are pre-set with glass fiber weaving. Lines 11, transverse positioning lines 12 and transverse positioning lines 13 are preformed with glass fiber braided longitudinal positioning lines 14, longitudinal positioning lines 15 and longitudinal positioning lines 16 at distances of 0, 150 mm, and 250 mm in the width direction of the surface of the prefabricated body 10. . The specific implementation steps are as follows:

[0062] 1) The profile too...

Embodiment 2

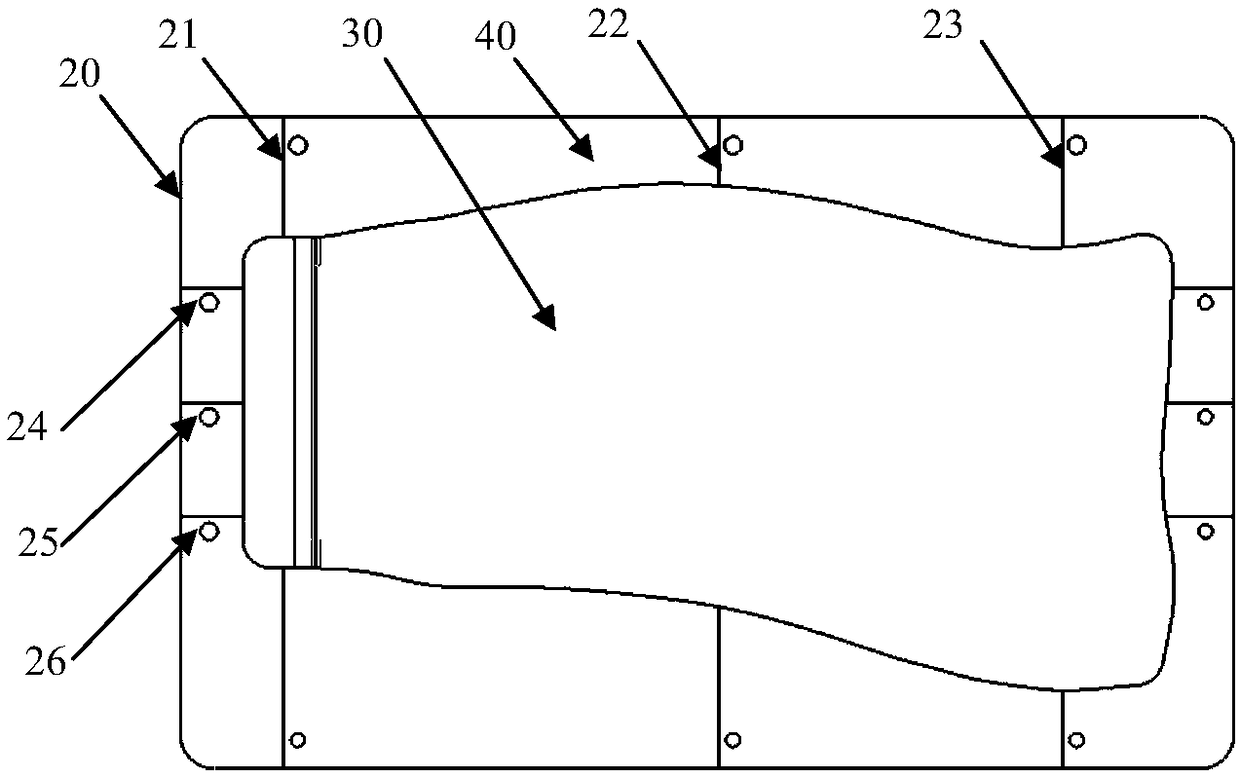

[0072] The prefabricated body 10 to be tested is a variable thickness 3D woven structure fan blade prefabricated body, the material is CCF800, and the fiber volume content of the material is 53%±3%; CCF800 is a T800 grade carbon fiber fabric with a specification of 6K produced by Shandong Weihai Development Company , the external dimensions of the parts are: 720mm×300mm×(3~50mm) (length×width×height), and the distances of 0mm, 190mm, 380mm, 530mm and 680mm in the surface length direction of the prefabricated body 10 are pre-set with glass fiber weaving The horizontal positioning line 11, the horizontal positioning line 17, the horizontal positioning line 12, the horizontal positioning line 18 and the horizontal positioning line 13 are preformed with a longitudinal positioning line 15 which adopts glass fiber weaving in the width direction 150mm of the prefabricated body 10 surface. The specific implementation steps are as follows:

[0073] 1) The profile tooling 20 is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com