Composite Building Material for Cementitious Material Wall Assembly

a technology of cementitious material and composite building material, which is applied in the direction of walls, coverings/linings, constructions, etc., can solve problems such as premature deterioration of structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

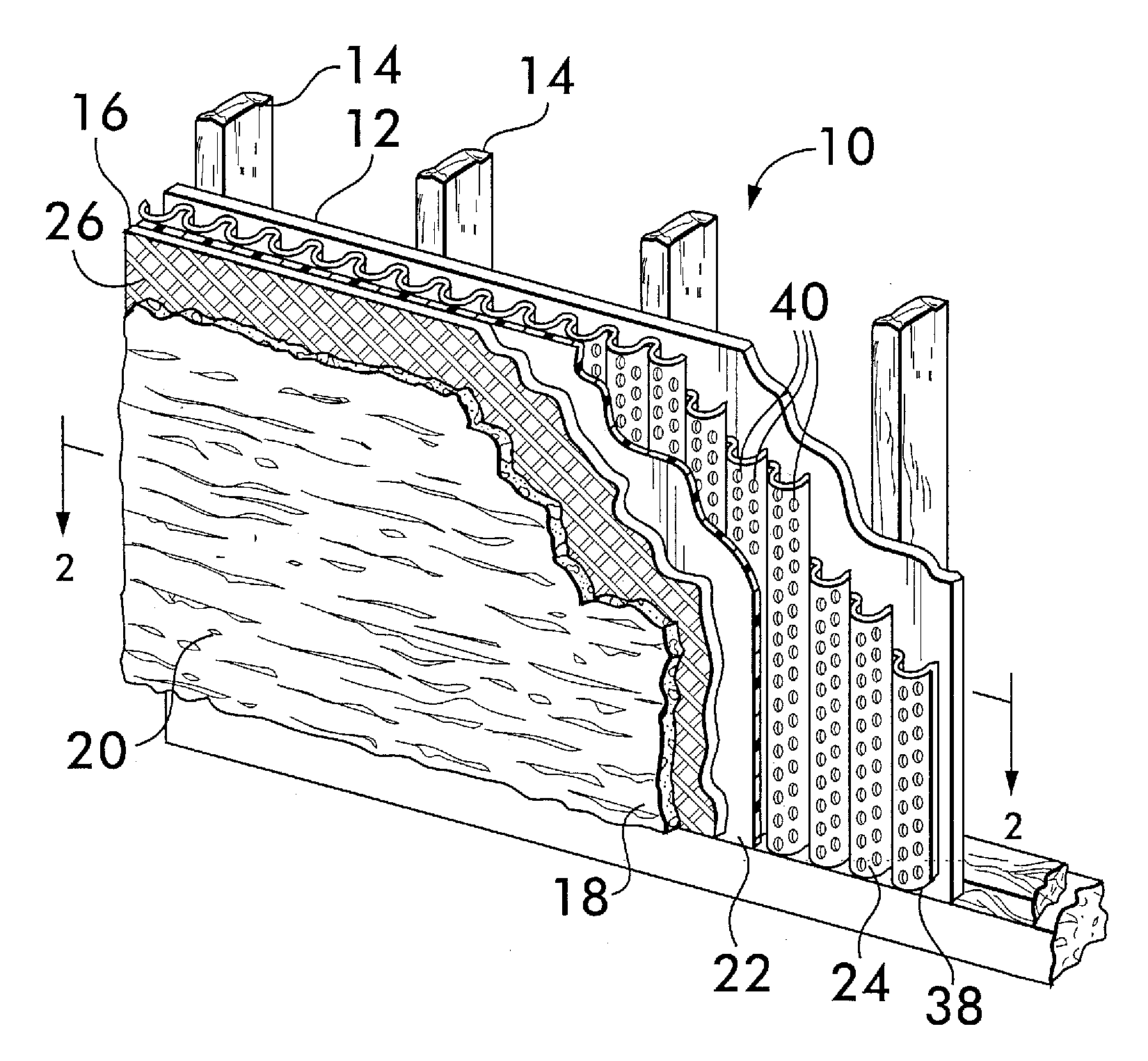

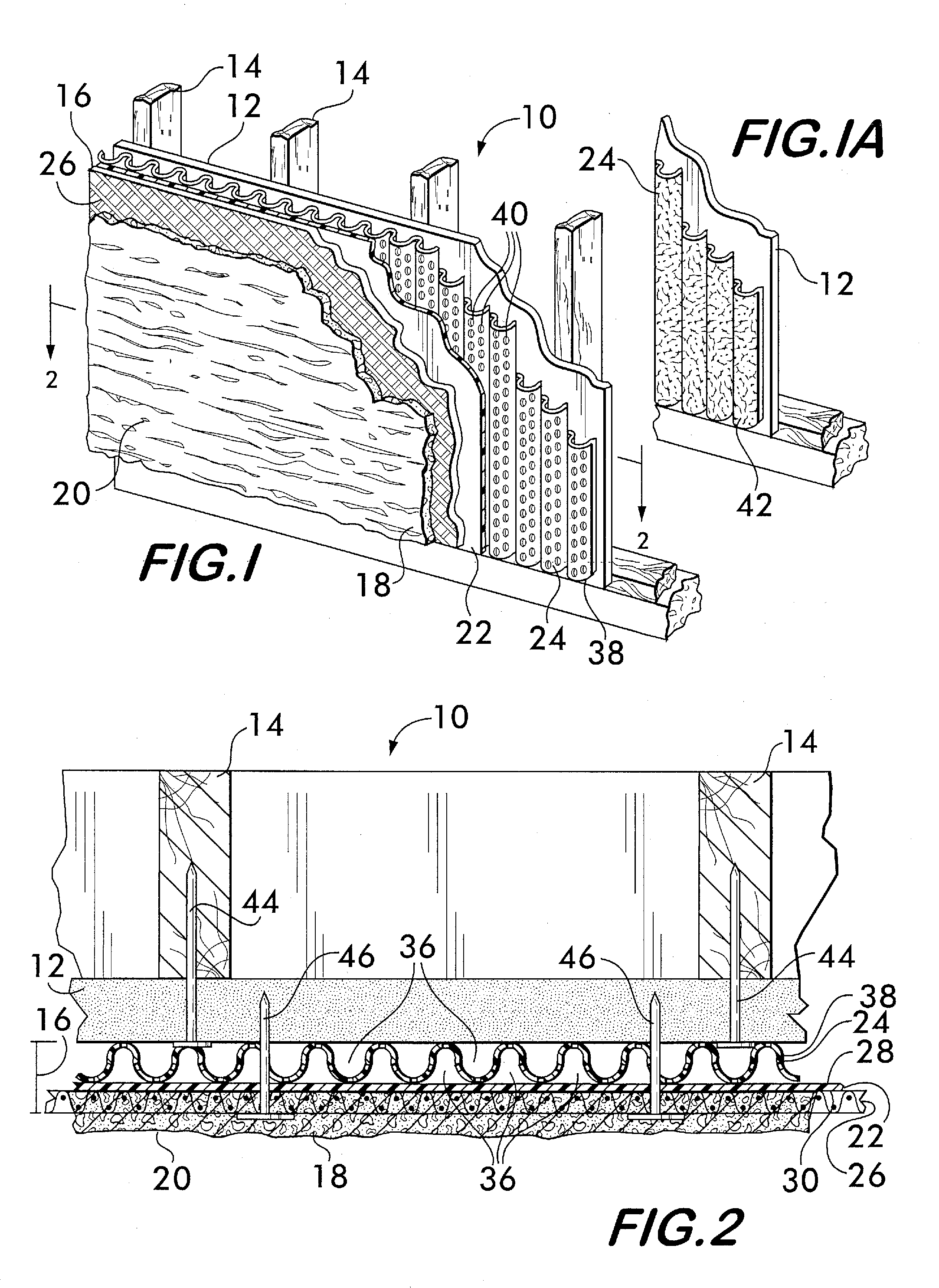

[0016] Referring now to the drawings, FIGS. 1 and 1A illustrate a wall assembly 10 of a building structure. Of course, the assembly can also be utilized to form roofs or other structures of a building. The assembly 10 includes an inner structural component, 12 or 14. In the illustrated embodiment, the inner structural component is provided as an inner sheathing member 12 that is affixed to support posts, or studs, 14. The inner sheathing member 12 can be panels of plywood, oriented strand board, particle board, insulated concrete, or like materials permitted by local building codes. Alternatively, the inner structural component can be provided by the support posts, or studs, 14, such as when open stud construction is utilized. In open stud construction, the sheathing members 12 would be eliminated.

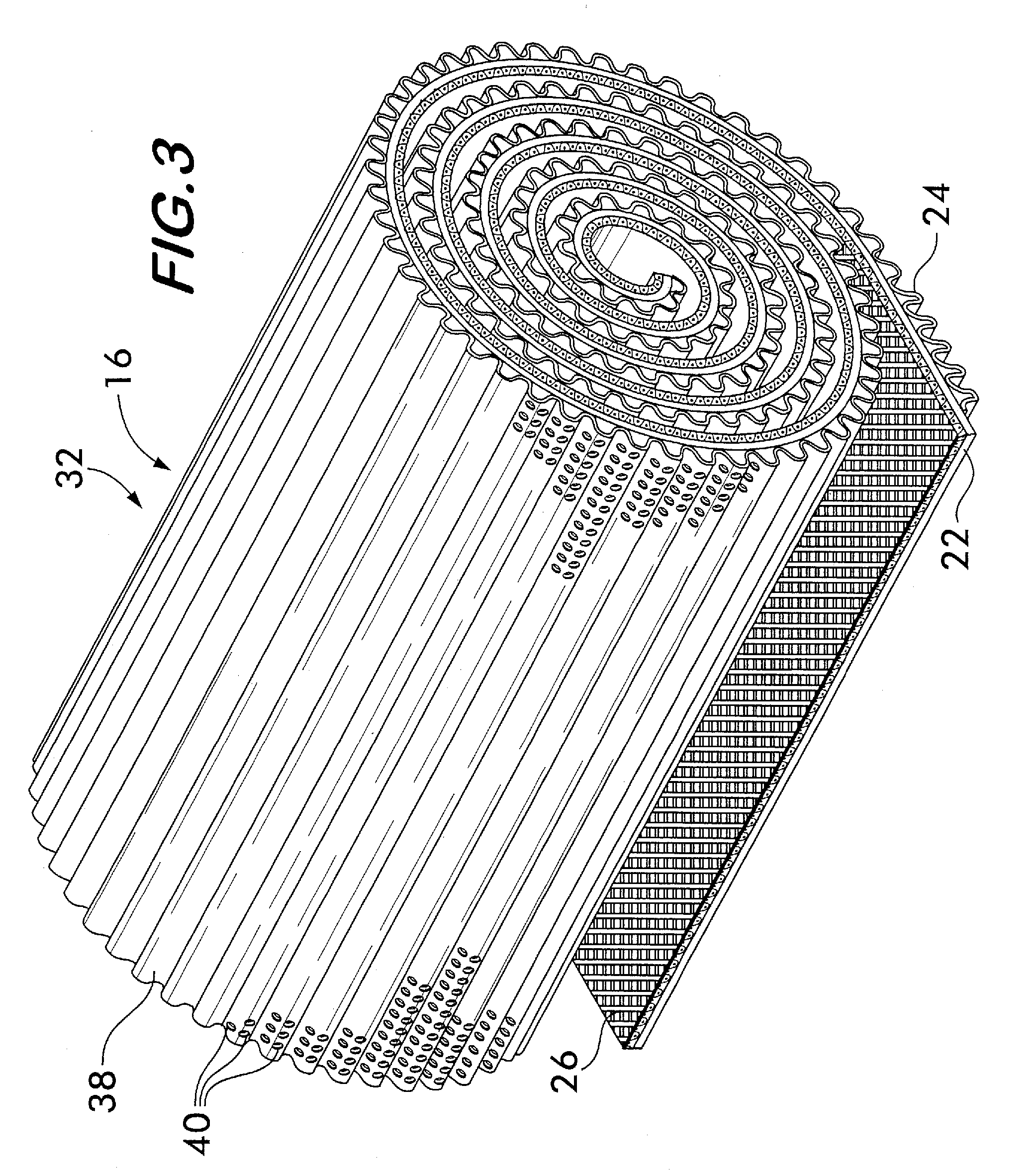

[0017] A composite building material 16 is fastened as an integral unit to an external side of the inner sheathing member 12. Alternatively, the composite building material is fastened di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cementitious | aaaaa | aaaaa |

| structures | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com