Dry hanging structure of fabricated hollow-out earthenware brick curtain wall and construction method of dry hanging structure of fabricated hollow-out earthenware brick curtain wall

A technology of prefabricated and hollow ceramic bricks, which is applied in the direction of walls, building components, building structures, etc., can solve the problems of cracking and damage of the side walls of hollow ceramic bricks, increase construction costs, and difficult operation, and achieve simple structure and low cost. Difficulty in construction and the effect of avoiding material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

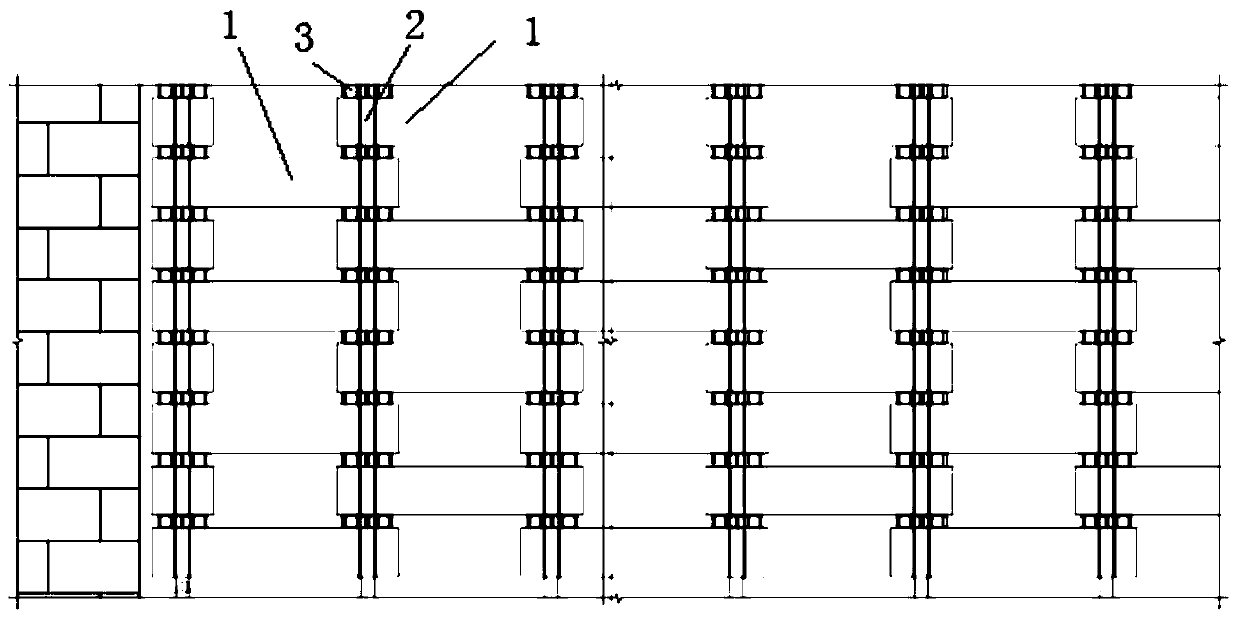

[0033] The following will combine Figure 1 to Figure 5 Describe in detail the dry-hanging structure of the assembled hollow ceramic brick curtain wall provided by the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and the detailed implementation and specific operation process are given. However, the present invention The scope of protection is not limited to the following embodiments, and those skilled in the art can modify and embellish it within the scope of not changing the spirit and content of the present invention.

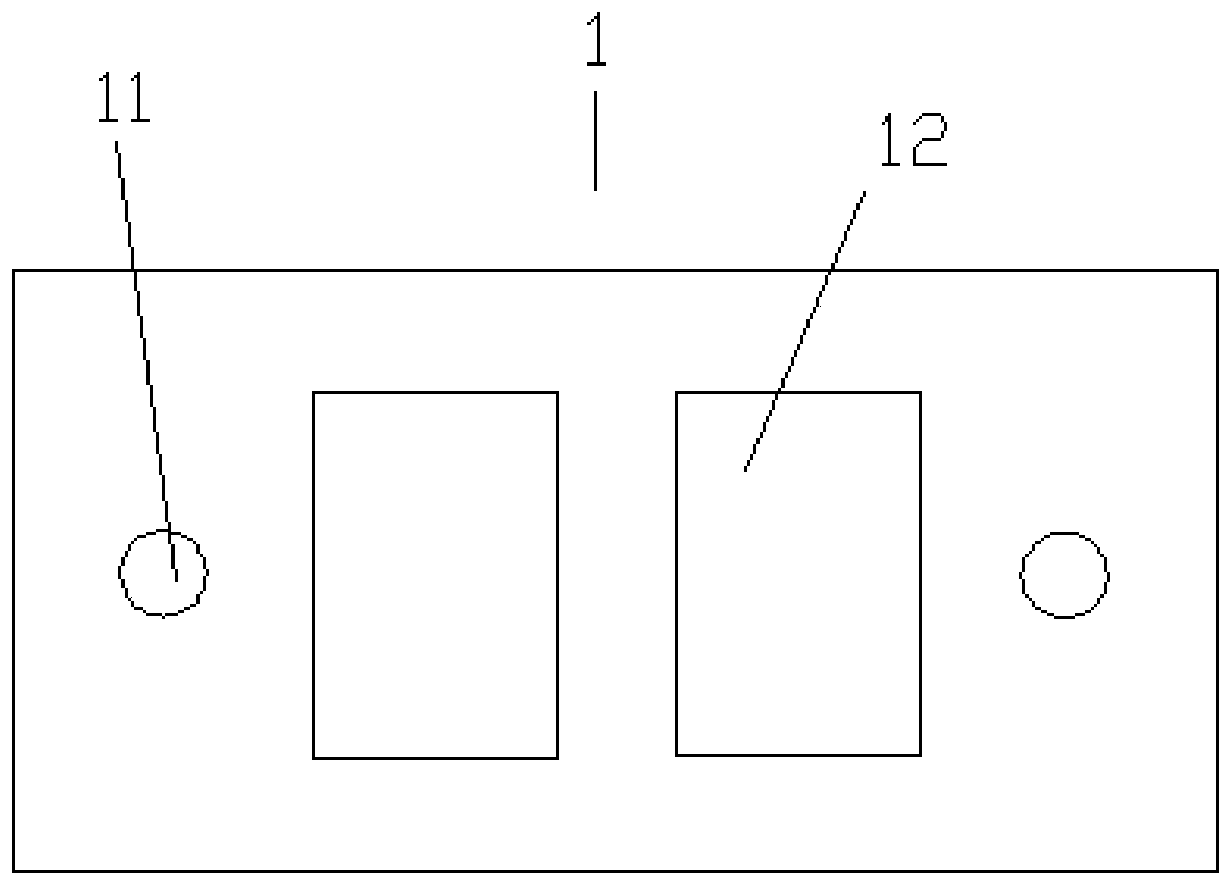

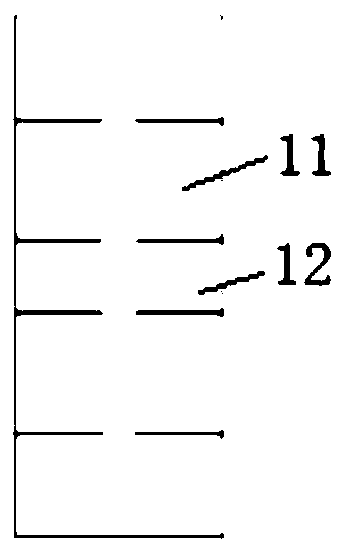

[0034] Please refer to Figure 1 to Figure 5 , a dry-hanging structure of an assembled hollow ceramic brick curtain wall, including a keel frame arranged on the side wall of the main body of the structure and a hanger assembly fixed on the keel frame, and several hollow ceramic bricks 1 are connected through the hanger assembly :

[0035] The hitch assembly includes several vertically a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com