A cold storage door closer

A door closer and cold storage door technology, applied in the field of cold storage doors, can solve problems such as cold storage door damage, cold storage door crash, cold storage door door leaf direction deviation, etc., and achieve the effects of improving door leaf displacement, prolonging service life, and reducing impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings of the description.

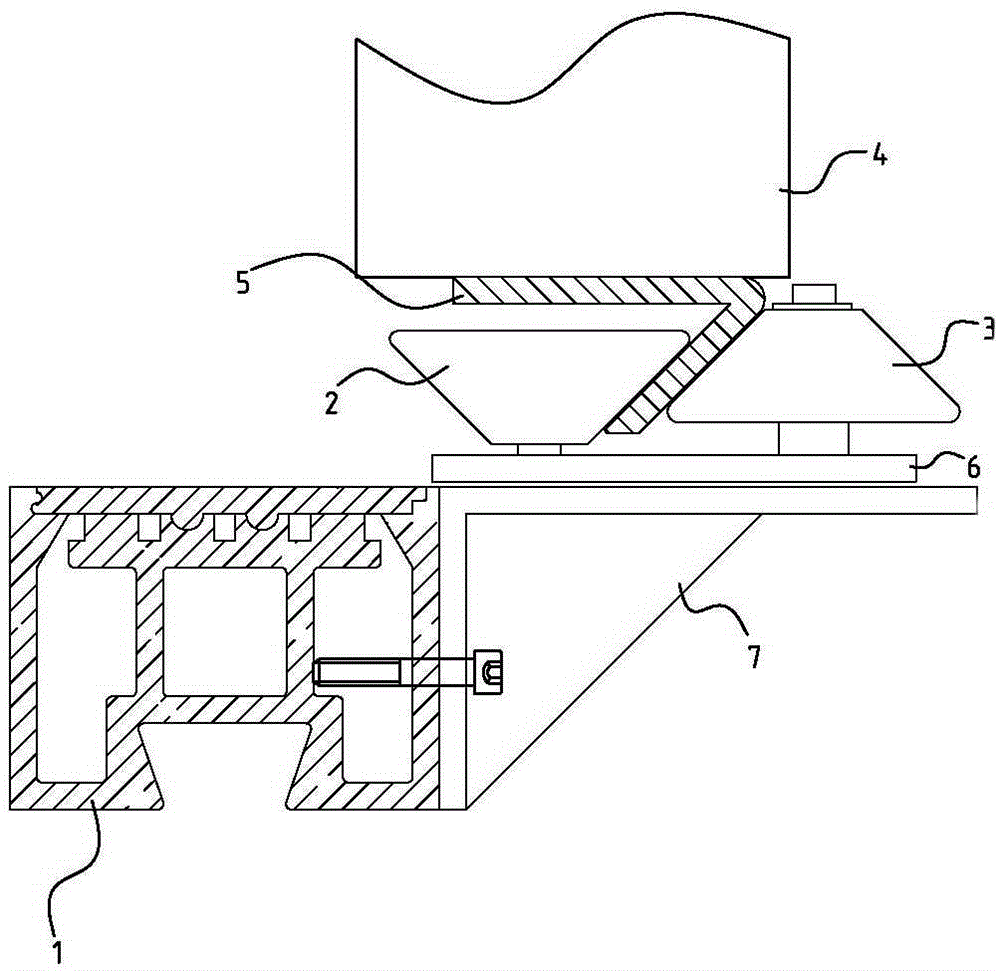

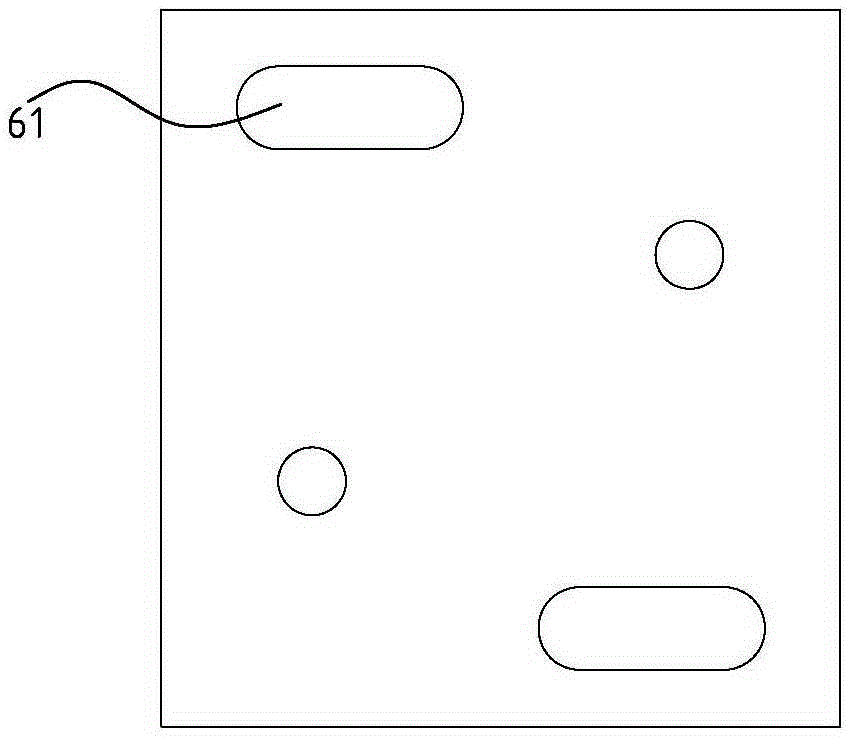

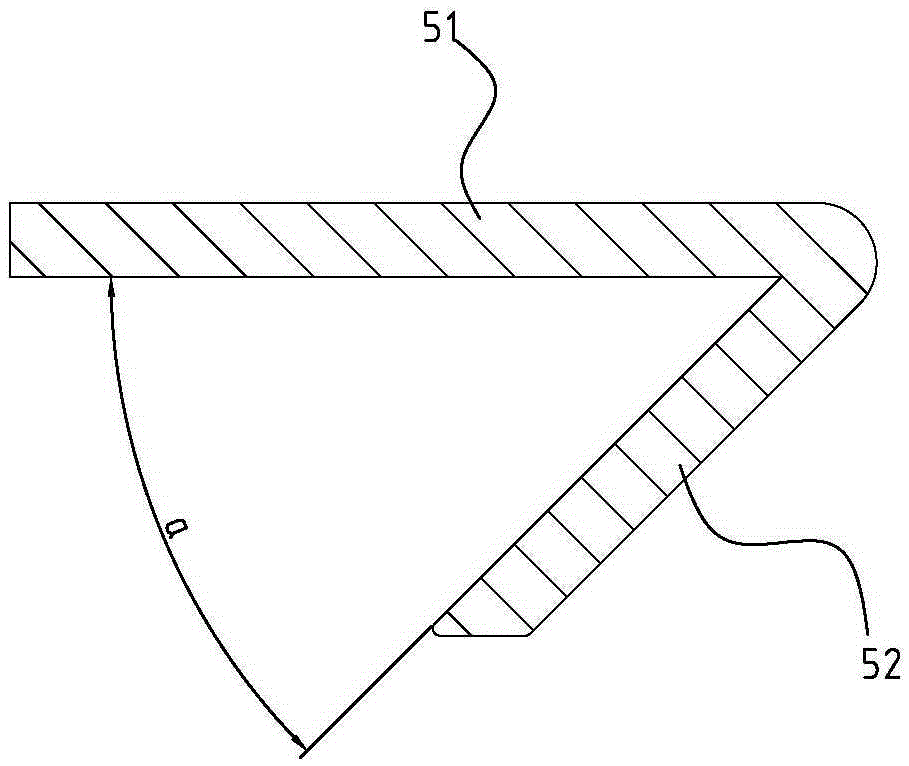

[0023] Such as figure 1 As shown, a cold storage door closer, the cold storage door of the present invention adopts the opening and closing form of translation, which includes a door closer guide rail 5 installed on the bottom of the cold storage door 4 and a door closer guide rail installed on the threshold 5 matching roller sets.

[0024] Such as figure 1 As shown, the roller set includes more than two first rollers 2 arranged on the inner side and second rollers 3 arranged on the outer side, and one set of first rollers 2 and second rollers 3 are arranged at one end of the threshold 1. Another set of first rollers 2 and second rollers 3 is provided at the other end, the first rollers 2 and the second rollers 3 can be set opposite to each other, or staggered by a certain distance, but the surface of the first roller 2 and the surface of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com