Multilayer composite lining

A multi-layer composite and fabric technology, applied in the field of decorative fabrics and textiles and clothing, can solve the problem that the aesthetics and decorative properties of the fabrics are not improved, and achieve the effects of improving the ability to keep out the cold and keeping warm, increasing the thickness, and increasing the sculptural effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

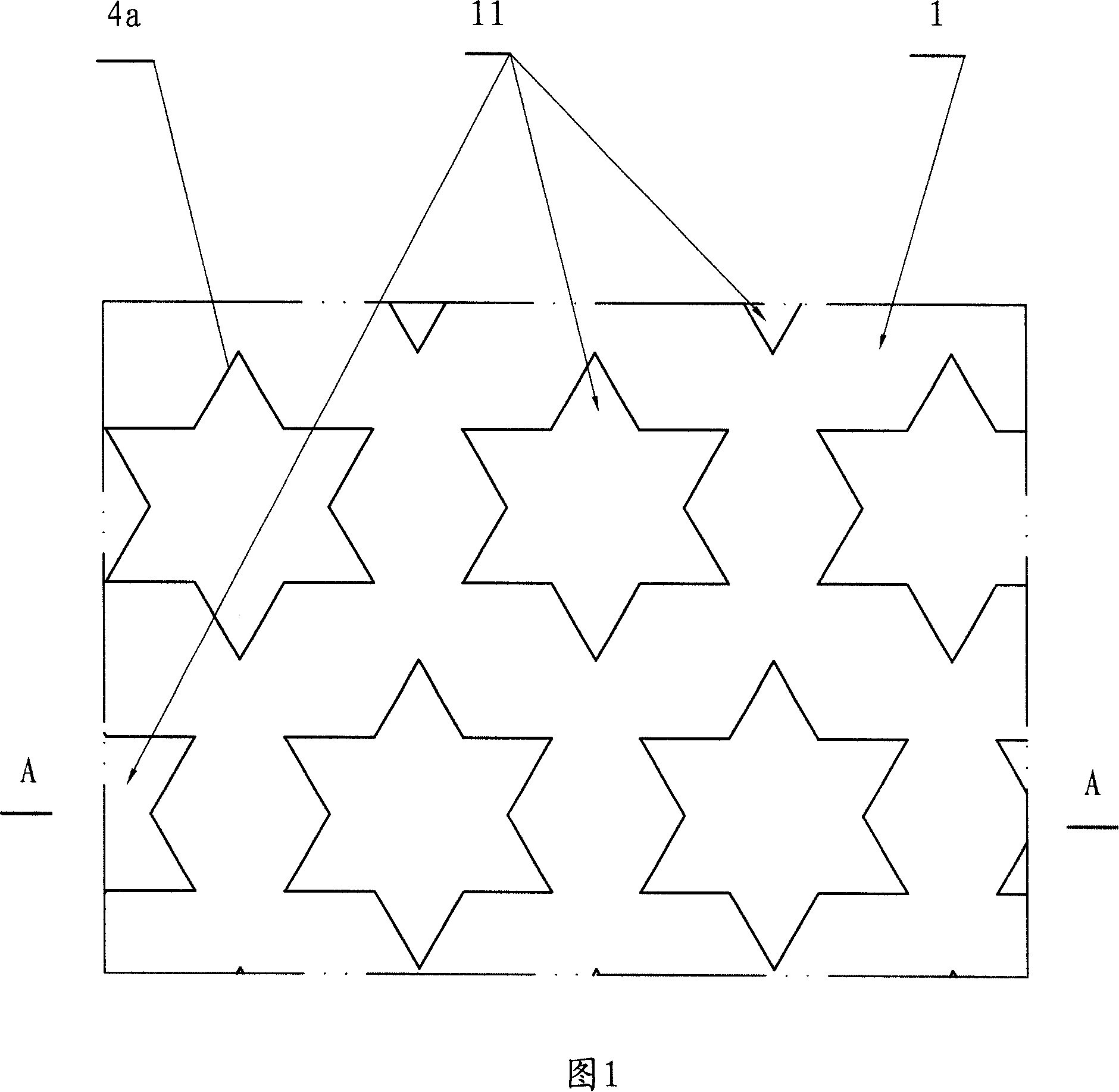

[0031] As shown in Figures 1 to 3, the multilayer composite fabric of the present invention is made of three layers of fabrics, the bottom layer 4 is a cotton cloth, the middle layer 2 is a flannelette of the fleece class, and the fluff is about 2.5-3.0mm, It is composed of the base fabric layer 2a and the fluff layer 2b. It is commonly called carved velvet in the market, and it is generally made of man-made fibers. The top layer, the surface layer 3, is made of cotton fabric. A good pattern is stitched with cotton or silk or artificial fiber thread, which is shown in Figure 1 and Figure 3. The stitching line 4 penetrates the three layers of fabrics, and the surface layer 1, the middle layer 2 and the bottom layer 3 are composited together, and the upper surface of the entire fabric is covered with hexagonal star-shaped closed areas, and then the stitched and composite fabric is washed, and the surface layer 1 of the washed composite fabric is hollowed out. The part of the enc...

Embodiment 2

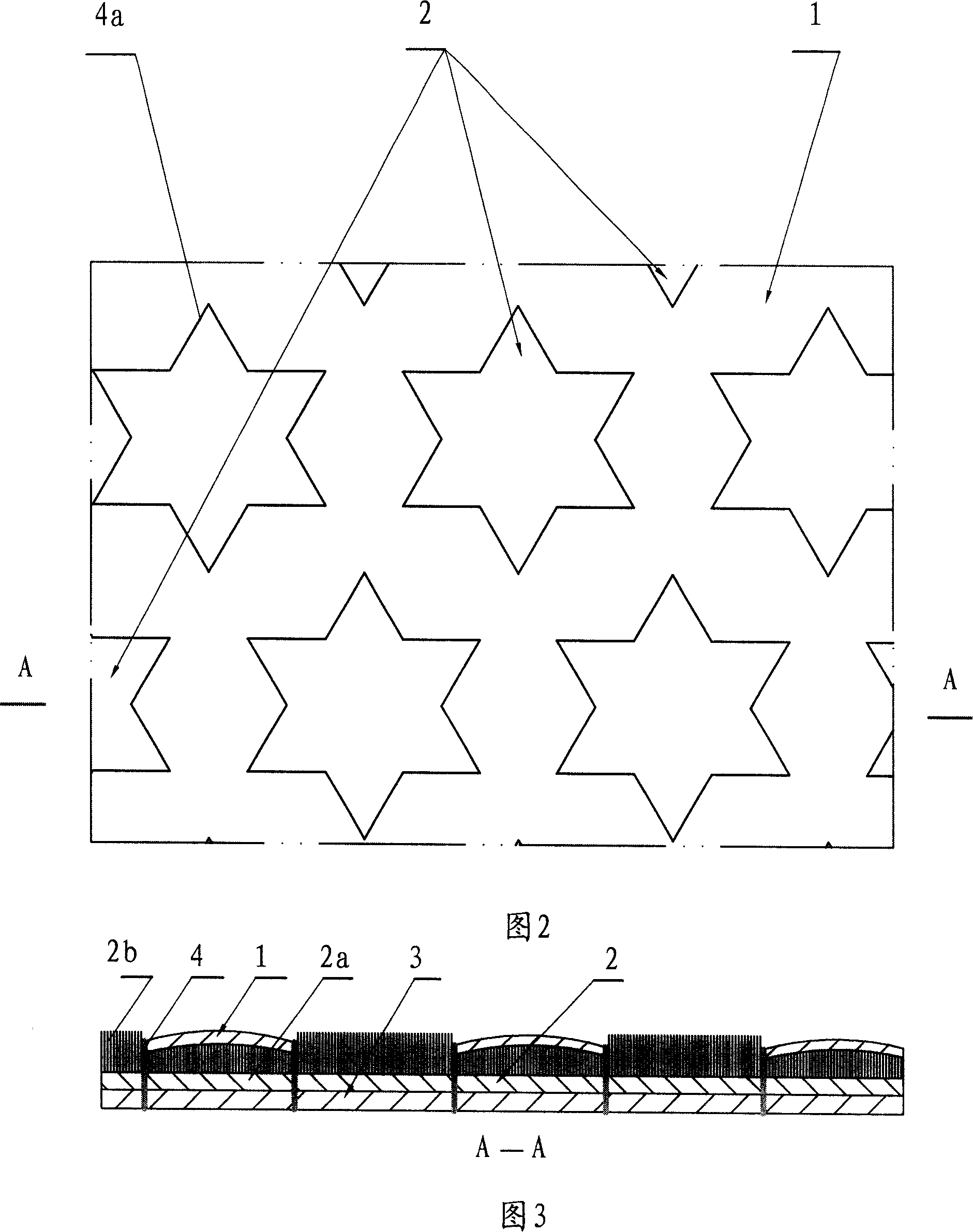

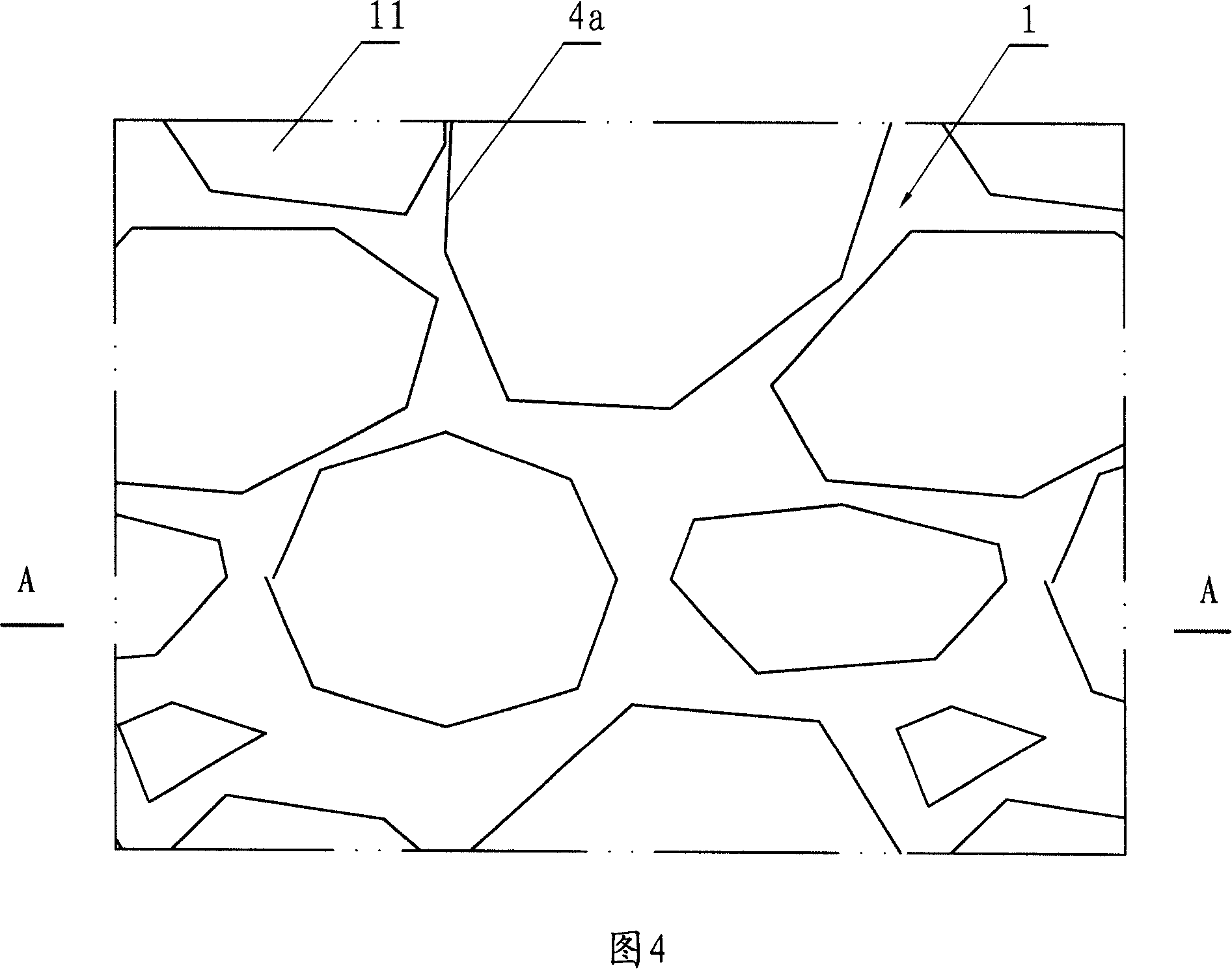

[0033] As shown in Figures 4 to 6, the multilayer composite fabric of the present invention is made of three layers of fabrics, the bottom layer 3 is a cotton cloth, the middle layer 2 is a flannelette of flocking class, and has a base cloth layer 2a and a fluff layer 2b. The uppermost layer, that is, the surface layer 1 is cotton fabric. After the three layers of fabrics are aligned and laminated, use an embroidery machine to sew with cotton or silk or artificial fiber threads according to the designed pattern. After sewing, see Figure 4 and Figure 6 As shown in , stitch 4 penetrates the three layers of fabric and joins them together. Then, dye, wash, and sand the fabric that is stitched and composited, and then hollow out the surface layer of the composite fabric to remove the part of the closed area and part of the surface layer fabric 11 formed by the seam stitches 4 on the surface layer, so that the composite is good. The finished fabric has just the exposed suede that is...

Embodiment 3

[0035] As shown in Figures 7 to 10, the multilayer composite fabric of the present invention is made of three layers of fabrics, the bottom layer 3 is a cotton fabric for the lining, the middle layer 2 is a brushed fabric fabric with longer fluff, and the upper layer is the surface. Layer 1 is a smooth cotton fabric. As can be seen from Figure 10, the middle layer 2 is composed of the base fabric layer 2a and the fluff layer 2b. After the three layers of fabrics are aligned and stacked, the cotton or silk fabrics are used according to the designed pattern by the machine. Quality or man-made fiber yarn 4 is stitched up, and the fabric that is stitched and composited is stitched and washed with water, and then the partially closed area formed by the stitching stitches 4a is cut into semi-scalloped shapes 5 one by one as shown in Figure 8, these The root ends of the semicircular teeth 5 are still connected to the stitches 4, and then these teeth 5 are turned over, the front side i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com