Sandwich structure and honeycomb structure core

A honeycomb structure and sandwich technology, which is applied in the field of sandwich structure and honeycomb structure core, can solve the problems of impact resistance, shock absorption and buffering, insufficient energy absorption, etc., and achieve multi-functional comprehensive performance, good energy absorption and crush deformation, The effect of high energy absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

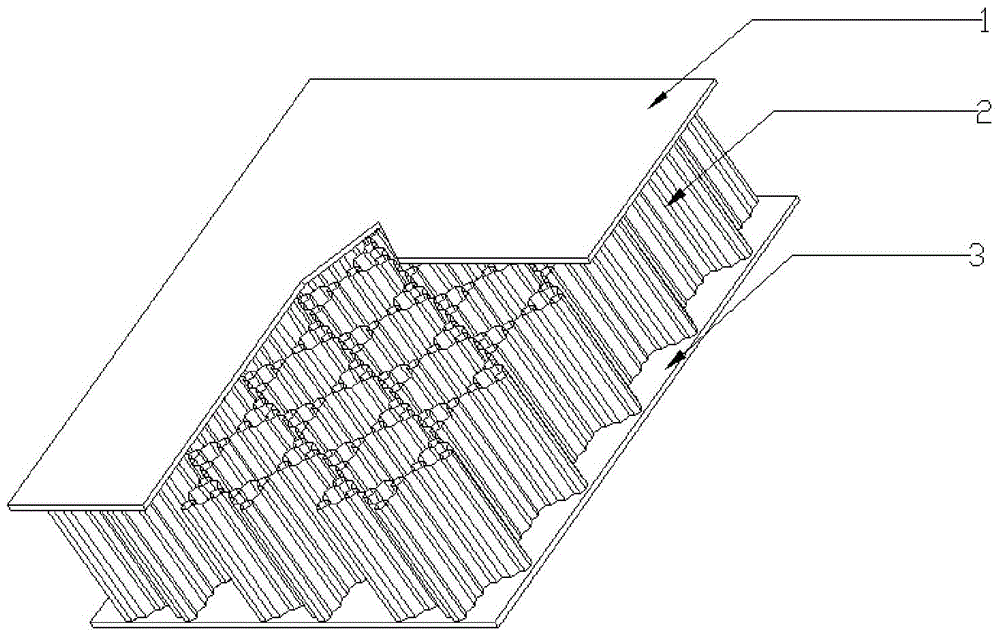

[0059] Embodiment 1 is the sandwich plate that is the core matrix with the multi-stage honeycomb structure, and its structure is as follows figure 2 As shown, it includes an upper plane plate 1, a core body 2 and a lower plane plate 3. The upper plane plate 1 and the core body 2 as well as the core body 2 and the lower plane plate 3 are connected by bonding. The matrix materials constituting the upper plane plate 1, the lower plane plate 3, and the core body 2 can be made of different materials according to the requirements of different fields, and are not limited to metal materials.

Embodiment 2

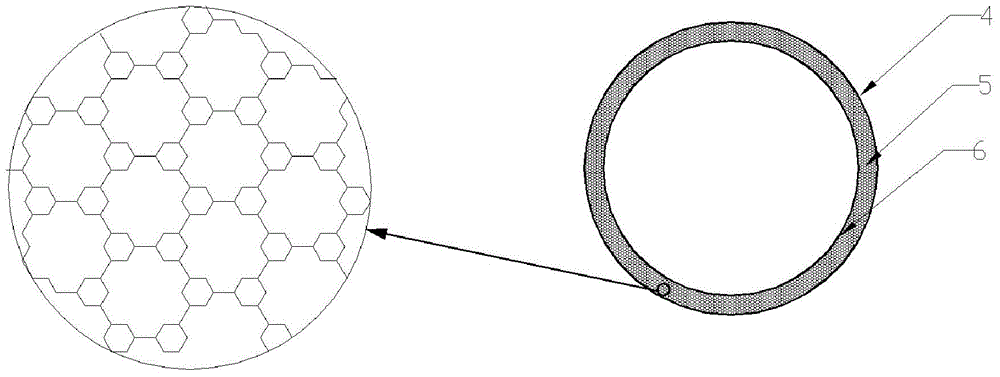

[0061] Embodiment 2 is a sandwich pipe material with a multi-level honeycomb structure as the core matrix, and its structure is as follows image 3 As shown, it includes an outer tube 4 , a core 5 and an inner tube 6 . The outer tube 4 and the core body 5 as well as the core body 5 and the inner tube 6 are also connected by bonding. Similarly, the matrix materials constituting the outer tube 4, the core body 5, and the inner tube 6 can be made of different materials according to the requirements of different fields, and are not limited to metal materials.

Embodiment 3

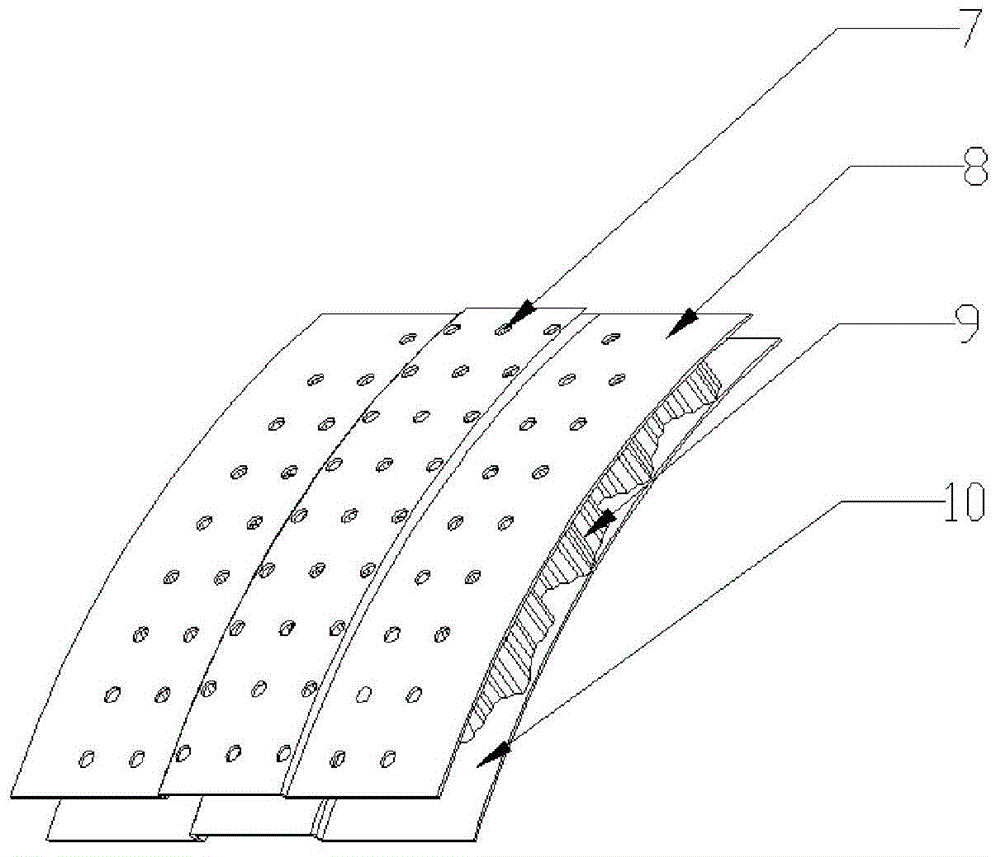

[0063] Embodiment 3 is a sandwich curved panel with a multi-level honeycomb structure as the core matrix. Its structure is shown in FIG. Wherein the upper curved panel 8 and the lower curved panel 10 are provided with lightening holes 7; the upper curved panel 8 and the core 9 and the core 9 and the lower curved panel 10 are connected by bonding. The matrix materials constituting the upper curved panel 8, the core body 9 and the lower curved panel 10 can be made of different materials according to the requirements of different fields, and are not limited to metal materials.

[0064] When the core needs to have a strong energy absorption capacity, by increasing the weight-reducing holes 7 and reducing the thickness of the curved panel, the weight of the sandwich curved panel structure can be effectively reduced without affecting its performance, which is useful in the automotive and aerospace fields Wide application prospects.

[0065] The manufacturing process of the above-me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com