Bottom thread control mechanism for sewing machine

A control mechanism and technology for sewing machines, which are applied to the ferrule mechanism for sewing machines, sewing machine components, sewing equipment, etc., can solve the problems of inconvenient disassembly and maintenance, poor operability, etc., and achieve convenient disassembly and maintenance, improve production efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

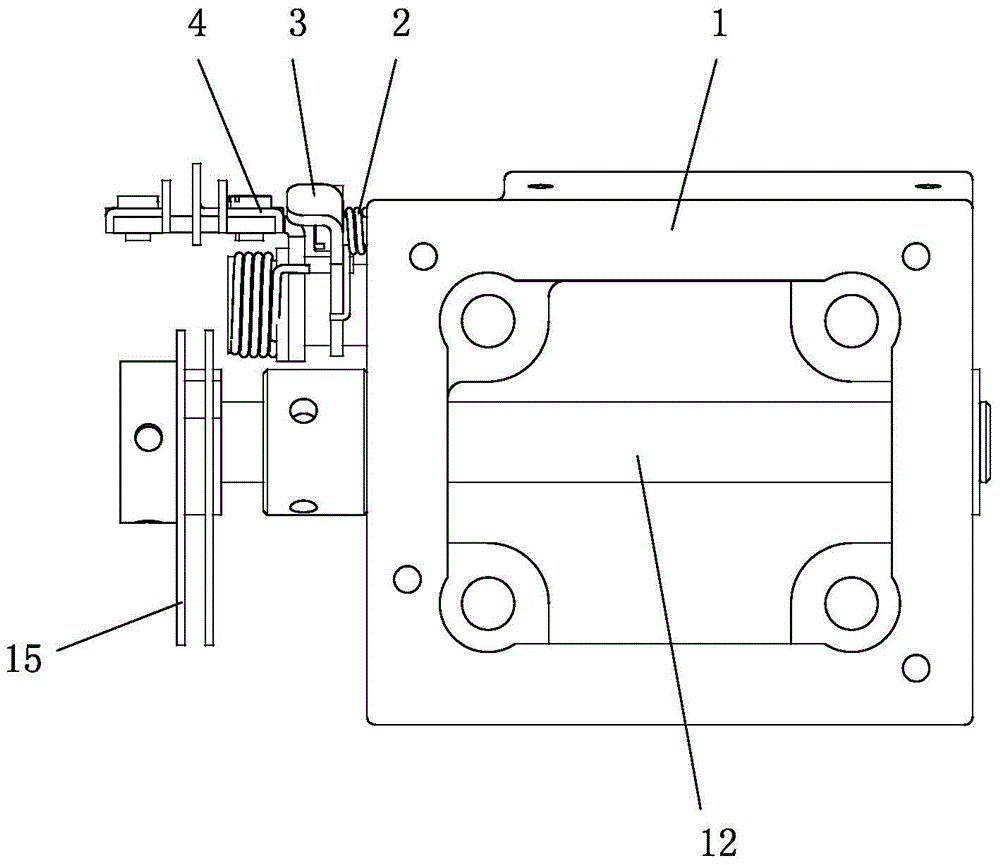

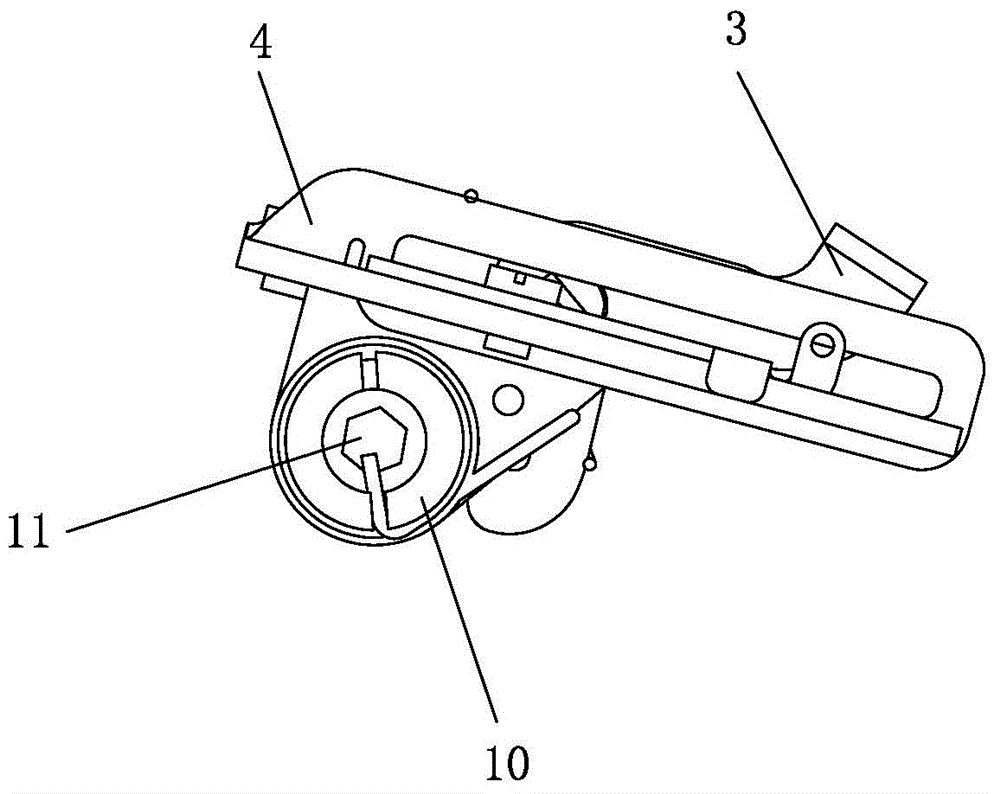

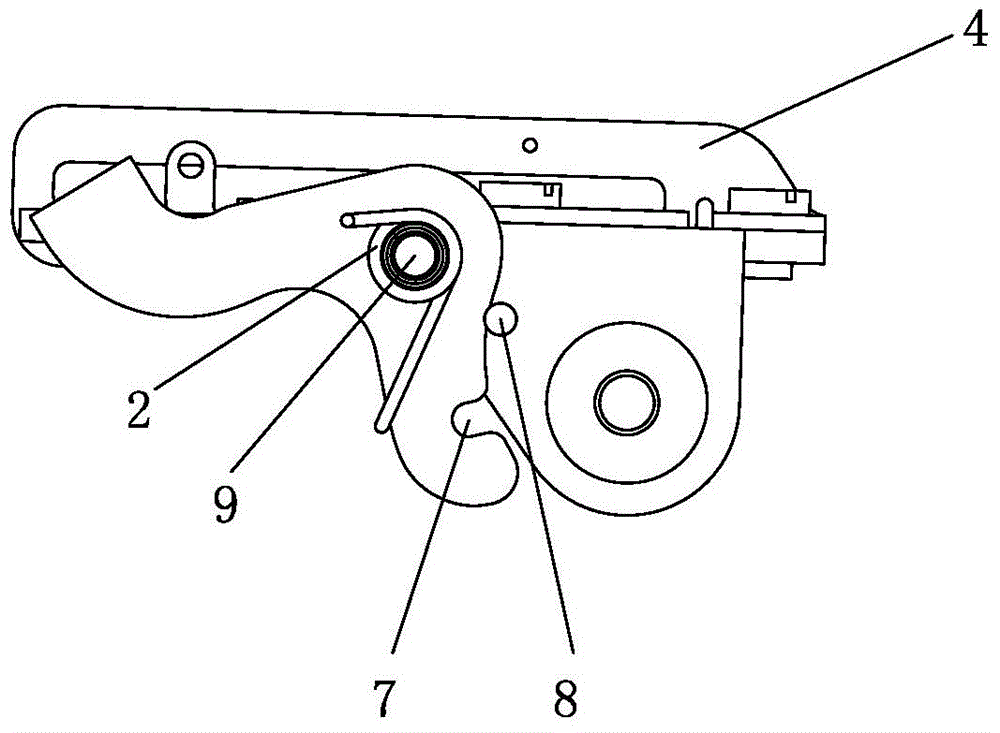

[0019] The present invention will be further described below with specific embodiment, see figure 1 -6:

[0020] A bottom thread control mechanism of a sewing machine, which includes a pin shaft with one end fixed on the casing 1, on the pin shaft is provided a threading frame wrench 3 that rotates around it and is driven by the first return torsion spring 2 to automatically reset. One side of the frame wrench 3 is provided with a wire frame 4, the wire frame 4 is connected with the block 5, the block 5 is fixed on the casing 1, the wire frame 4 rotates around the block 5 and is driven by the second reset torsion spring 6 The drive automatically resets, the wire frame wrench 3 is provided with a card slot 7, and the wire frame 4 is provided with a limit pin 8, and the limit pin 8 is in the working state when it is arranged in the card slot 7 of the wire frame wrench 3 , the limit pin 8 is in the threading state of the wiring frame 4 after disengaging from the card slot 7 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com