Sewing machine based on automatic template split synchronizing wheel apparatus

A sewing machine and synchronous wheel technology, applied in the field of locket sewing machines, can solve the problems of fabric tearing, inability to control itself, inconvenient operation, etc., and achieve the effects of increasing elastic friction, improving sewing performance, and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

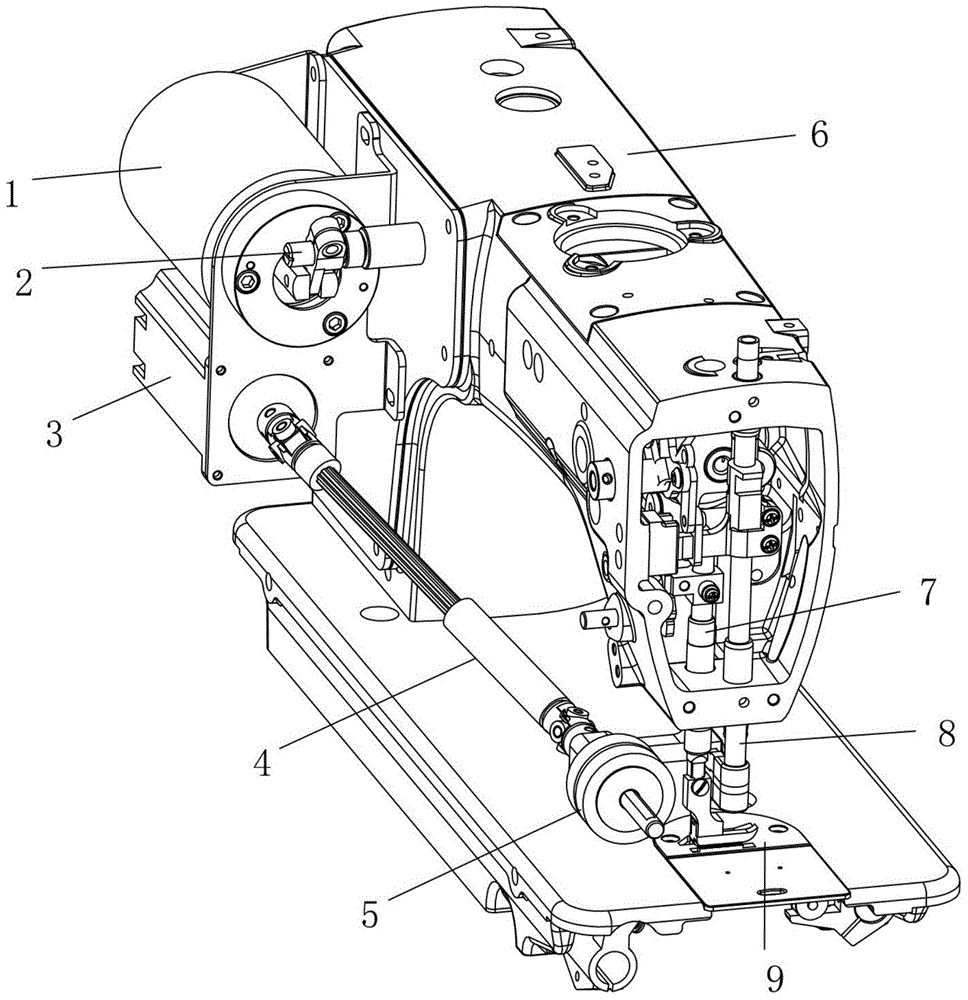

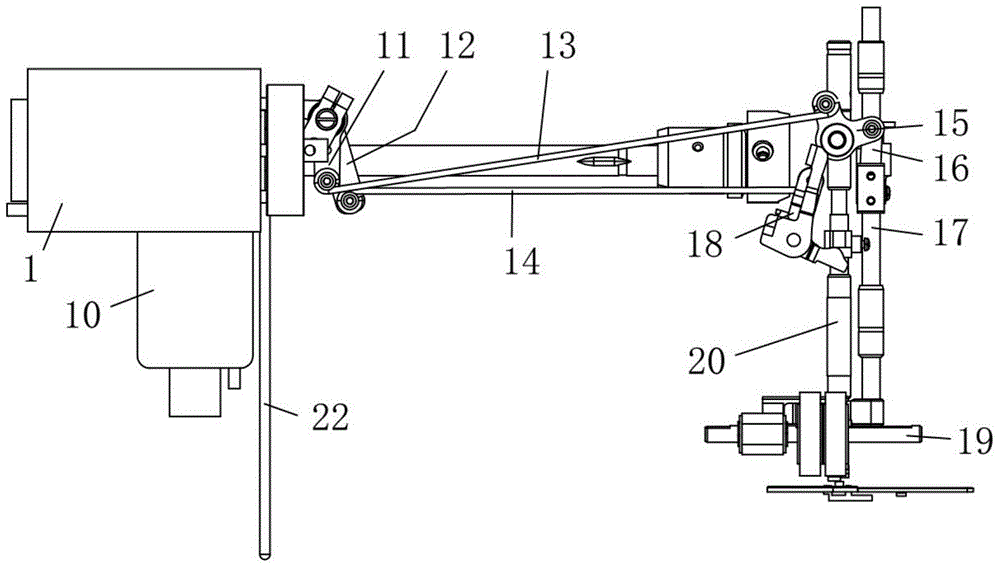

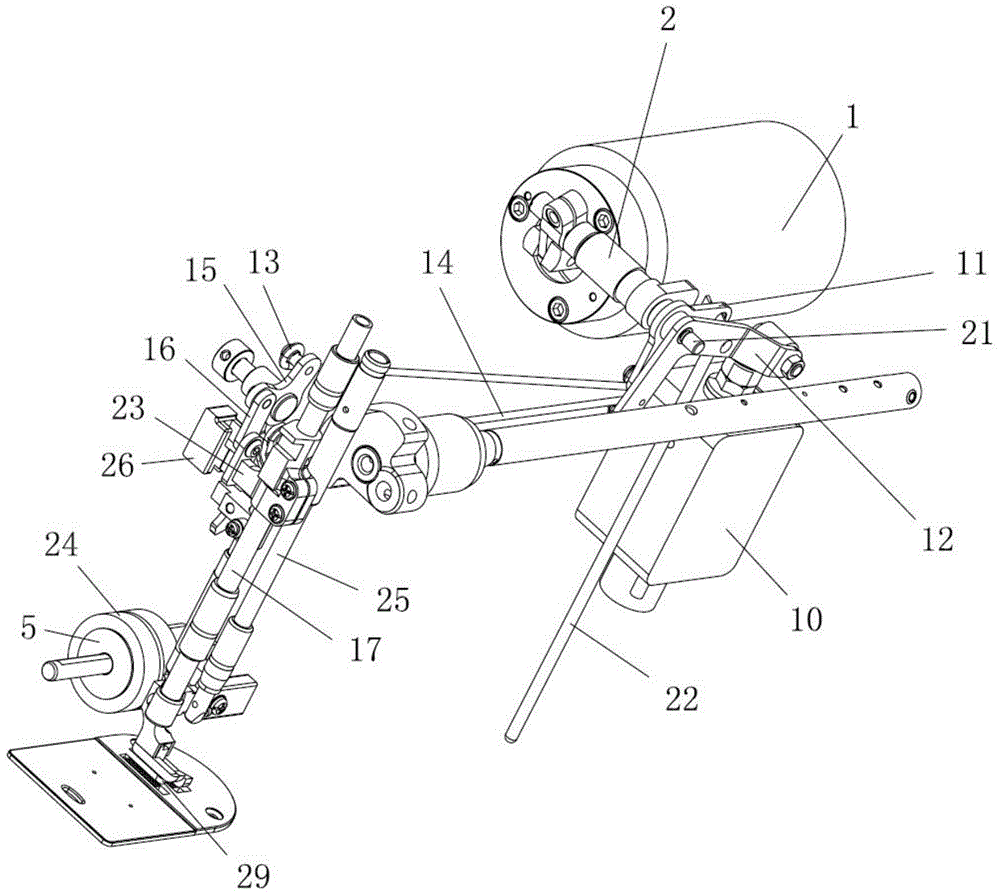

[0024] A sewing machine based on a fully automatic template split synchronous wheel device, comprising a sewing machine main body, a tug wheel lifting mechanism 8 and a presser foot lifting mechanism 7 are arranged on the sewing machine main body, and the casing 6 rear cover of the sewing machine main body is provided with a lifting pressure mechanism. The tugboat electromagnet 1 and the lifting and pressing tugboat electromagnet 1 are attracted to make the swing crank drive the lifting and pressing tugboat crank shaft 2 to rotate, one end of the tugboat crank shaft 2 extends into the inside of the casing 6, and the lever 28 of the crank shaft is against the tugboat lifting right lever 11 The right end of the right end of the tugboat lifts the rotation fulcrum of the right lever 11 and is installed on the casing 6. Through the rotation of the lever, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com